English (US)

6

Lifting KPV, KPVS (vertical) pumps

Before unloading the product, move the shipping container to an

open area equipped with an overhead lifting mechanism.

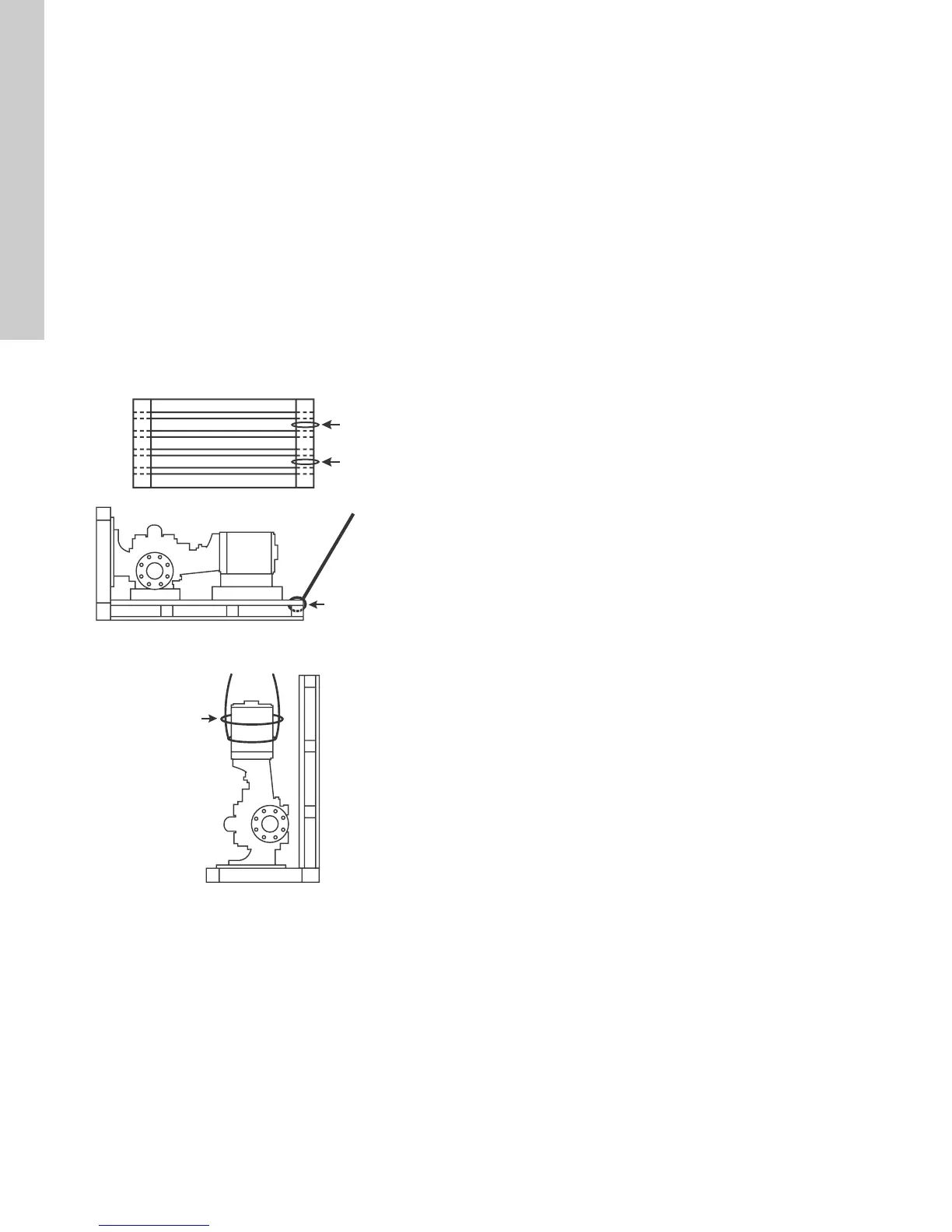

1. Install a lifting strap on each of the pallet's 4 x 4 in. floor

boards. Attach the straps securely at the corners of the pallet

near the top of the pump motor. See fig. 3.

2. Attach the other end of the straps to a lifting hook.

3. Rotate the pump assembly to the vertical position.

4. Remove excess packaging for easier access to the pump

assembly.

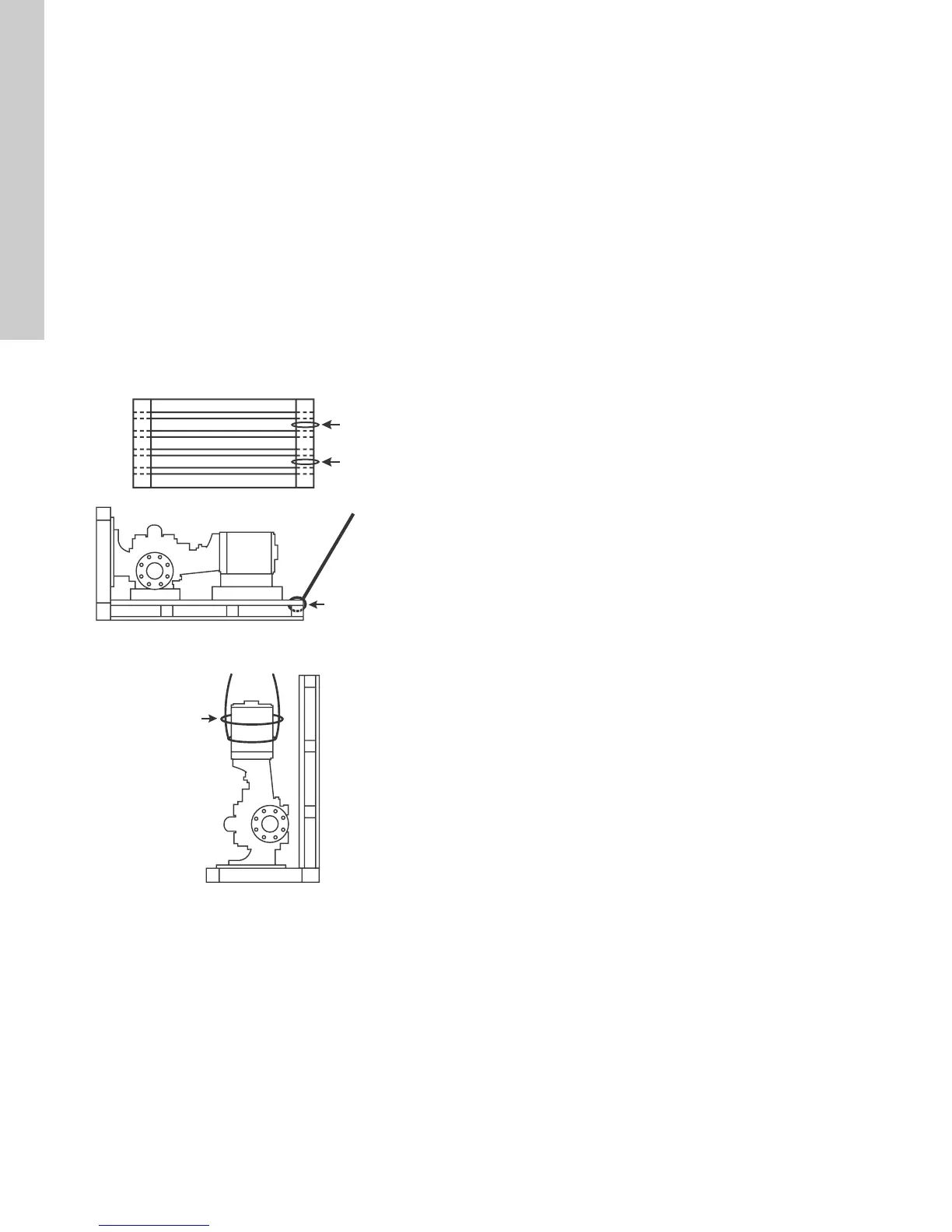

5. Position two lifting straps around the motor, below the junction

box and 180 degrees apart. See fig. 4.

6. Tighten the straps securely.

7. Attach the free ends of the lifting straps to a lifting hook.

8. Tie a strap around the upper portion of the motor to hold the

lifting strips tight against the motor. Ensure the straps stay

tight against the motor while moving the pump assembly.

9. Utilize appropriately rated lifting equipment to move the pump

assembly to the installation location.

Fig. 3 KPV, KPVS pumps, correct lifting points for pallet

Fig. 4 KPV, KPVS pumps, correct lifting points

3.2 Inspecting the product

• Check that the product received is in accordance with the

order.

• Check that the voltage and frequency of the product match the

voltage and frequency of the installation site. See section

7.3 Pump identification.

• Check the product for defects and damage immediately upon

arrival. Any accessories ordered will be packed in a separate

container and shipped with the product.

• If any equipment is damaged in transit, promptly report this to

the carrier's agent. Make complete notations on the freight bill.

3.3 Temporary storage after delivery

If the product is not to be installed and operated immediately after

receiving it, store it in a clean, dry place at a moderate ambient

temperature. Protect the pump from moisture, dust, dirt and

foreign bodies. Prior to and during storage, we recommend these

precautions:

1. Ensure that the bearings are filled with the recommended

grease to prevent moisture from entering around the shaft.

See section 8.1.2 Lubricating the pump bearings.

2. Ensure that the inlet and outlet ports of the pump and all other

openings are covered with cardboard, wood or masking tape

to prevent foreign objects from entering the pump.

3. Cover the product with a tarpaulin or other suitable covering if

it is to be stored where there is no protective covering.

4. Rotate the shaft 2 turns every 2 weeks to coat the bearings,

stuffing box (packing), and shaft seal faces with lubricant to

impede oxidation and corrosion.

5. This equipment contains vegetable fiber gaskets that can dry

out during long storage periods. To avoid leaks, fill the pump

with water and let stand for 24 hours prior to startup or

pressure testing. Typically, this will allow the dry gaskets to

wick moisture back into themselves, sealing the pump.

6. Split case pumps must be pressurized only with the medium

they are intended to pump. Do not perform any pressurized

"air" test.

TM06 8345 0117 - TM06 8347 0117TM06 8348 0117

Attach lifting

straps to the

pallet

Use lifting

straps to

rotate the

pallet with the

pump

assembly to

vertical

position

Loading...

Loading...