7

English (US)

4. Installing the product

All installations must be performed by personnel experienced with

the placement, connection, and alignment of pumping equipment.

The following instructions are general in nature, and may not deal

with the specifics of your installation. Read these instructions

thoroughly before installing and operating your KP, KPV, or KPVS

pump.

4.1 Location

• Locate the pump as close as possible to the liquid supply. Use

the shortest and most direct inlet pipe practical. Refer to

section 4.4.2 Inlet pipe.

• Locate the pump below system level wherever possible. This

will facilitate priming, assure a steady liquid flow, and provide

a positive inlet pressure.

• The Net Positive Suction Head (NPSH) available must always

be equal to or exceed the required NPSH specified on the

pump performance curve. Make sure that sufficient NPSH is

provided at the inlet.

• Always allow sufficient accessibility space for maintenance

and inspection. Provide a clearance of 24 in. (610 mm) with

ample head room for use of overhead lifting equipment strong

enough to lift the product.

• Do not expose the product to sub-zero temperatures to

prevent the pumped liquid from freezing. If there is frost during

shutdown periods, see the shutdown information included in

section 8.8 Taking the product out of operation.

4.2 Pump foundation

Install the pump permanently on a firm, raised concrete

foundation of sufficient size to dampen any vibration and prevent

any deflection or shaft misalignment. The foundation may float on

springs or be a raised part of the floor.

Proceed like this:

1. Pour the foundation without interruption to 0.75 - 1.5 in. (20-

35 mm) below the final pump level.

2. Scour and groove the top surface of the foundation before the

concrete sets to provide a suitable bonding surface for the

grout.

3. Place anchor bolts in pipe sleeves for positioning allowance.

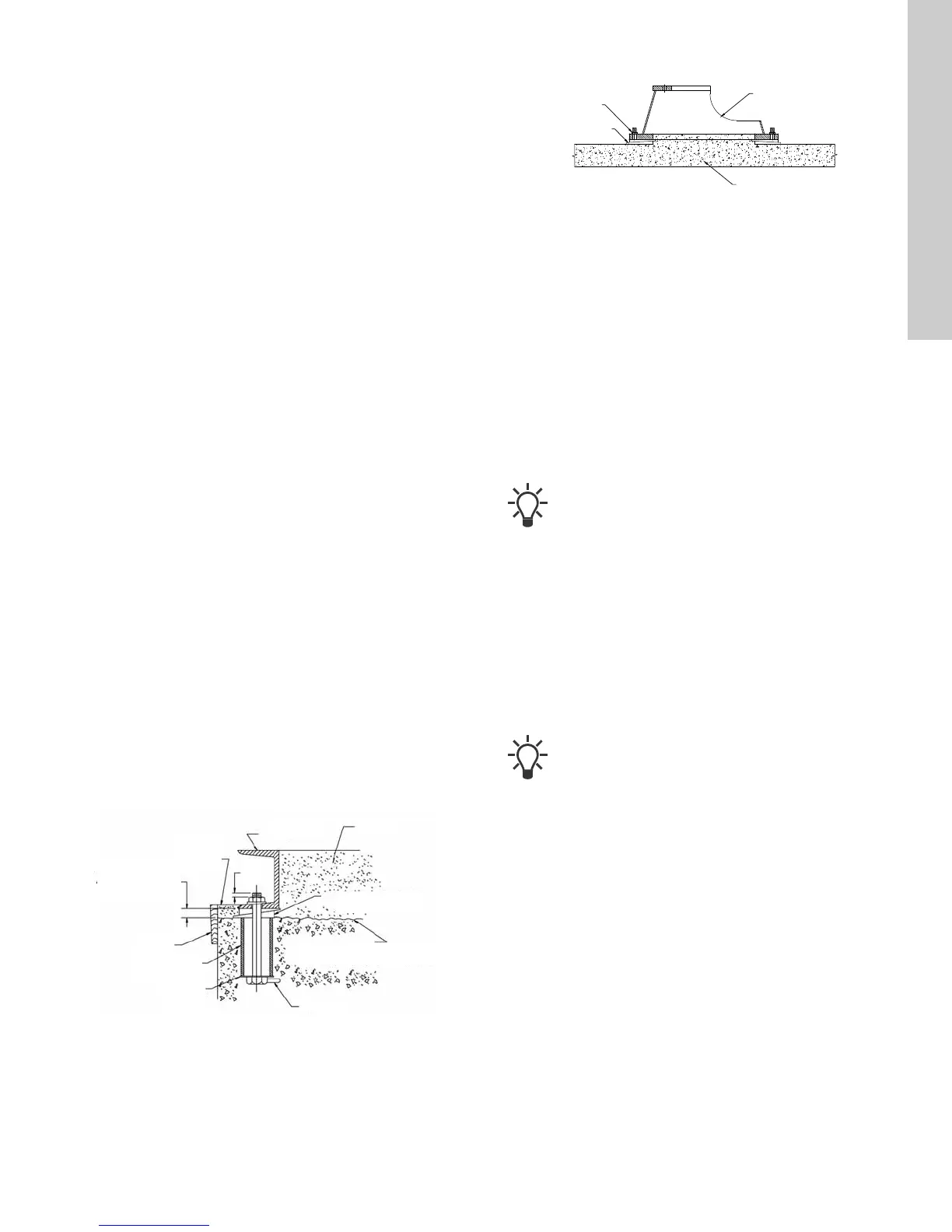

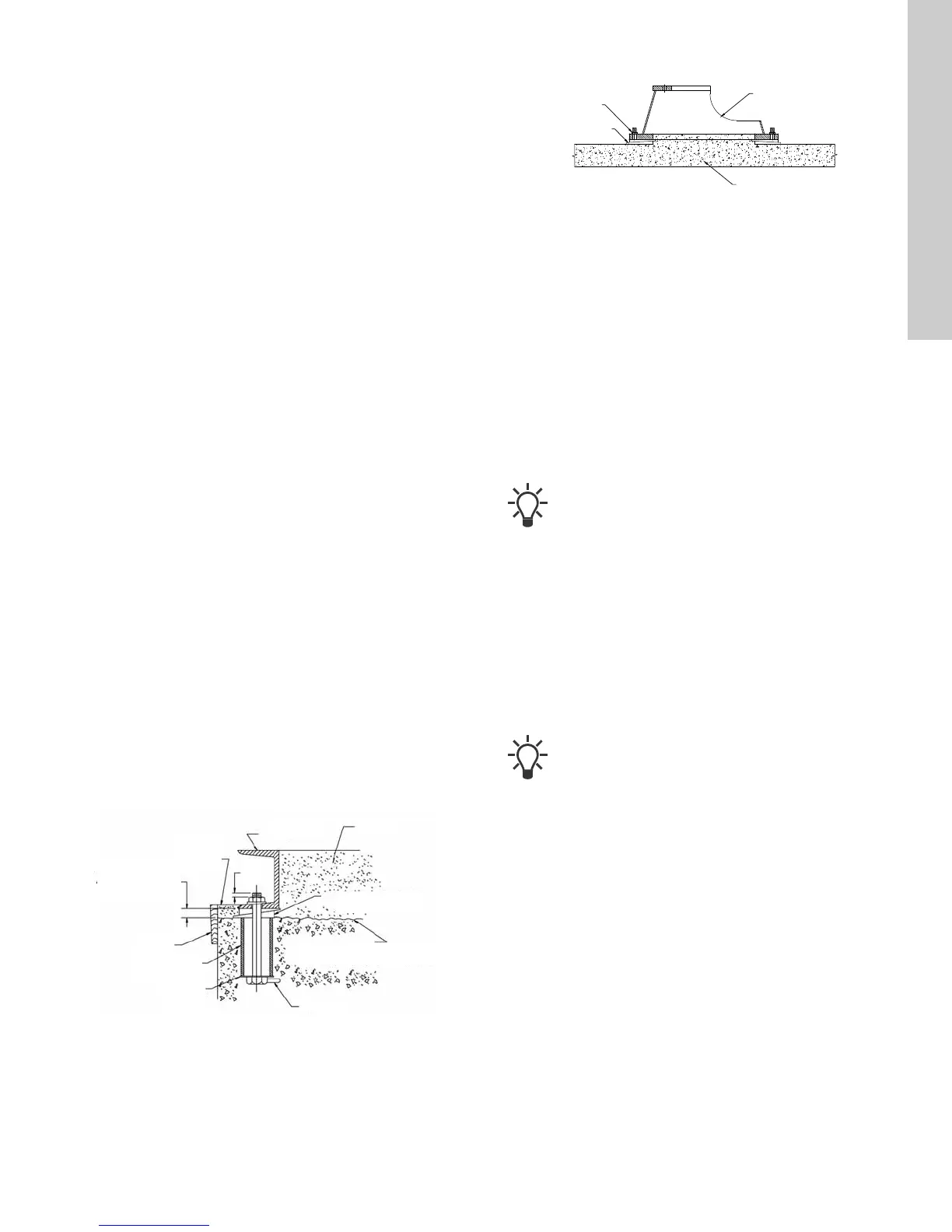

See fig. 5 and fig. 6.

4. Allow enough bolt length for grout, base, flange, nuts, and

washers.

5. Allow the foundation to cure several days before proceeding

to install the pump.

Fig. 5 KP anchor bolt installation

Fig. 6 KPV, KPVS anchor bolt installation

4.3 Securing the baseplate

When the raised concrete foundation has been poured and

allowed to set, proceed as follows:

1. Lower the base plate over the anchor bolts and rest it on loose

adjustment wedges or shims placed near each anchor bolt

and at intervals not exceeding 24 in. (610 mm) along each

side.

2. Place the shims or wedges so that they raise the bottom of the

base plate 0.75 in. - 1.25 in. (20-32 mm) above the pad,

allowing clearance for grout.

3. Level the pump shaft, flanges, and base plate using a spirit

level, adjusting the wedges or shims, as required.

4. Make sure that the pipes can be aligned to the pump flanges

without placing any strain on either flange.

5. After pump alignment has been established, put nuts on

anchor bolts and tighten them just enough to keep the base

plate from moving.

6. Construct a formwork around the concrete foundation and

pour grout inside and around the base plate. See fig. 5 for KP

and fig. 6 for KPV, KPVS. The grout will compensate for

uneven foundation, distribute the weight of the pump, and

prevent shifting.

7. Allow at least 24 hours for the grout to set before proceeding

with the pipe connections.

8. After the grout has thoroughly hardened, check the anchor

bolts and tighten them if necessary. Recheck the pump

alignment after tightening the anchor bolts.

TM05 4775 2512

Grout

Base plate

Finished grouting

0.75 to 1.25 in.

(20 to 32 mm)

allowance for

grout

Formwork

Pipe sleeve

Washer

Lug

Top of foundation

Wedges or shims

left in place

0.25

TM06 6124 0816

Place a spirit level on top of the pump to check that it

is level.

Use an approved, non-shrinking grout.

KPV, KPVS

stand

Anchor bolts for

supporting the base

Wedges or shims

(as required)

Grouted pad for

anchoring/

housekeeping

Loading...

Loading...