1-4

Lasting low relative humidity can cause washer contraction and ESD and cause problems

including loose mounting screws and circuit failure.

High temperature can accelerate the aging of insulation materials and significantly lower the

reliability and lifespan of the switch.

For the temperature and humidity requirements of different switch models, see technical

specifications in Hardware Information and Specifications.

Cleanliness

Dust buildup on the chassis might cause electrostatic adsorption and dust corrosion, resulting in

poor contact of metal connectors and contact points. This might shorten the device's lifetime and

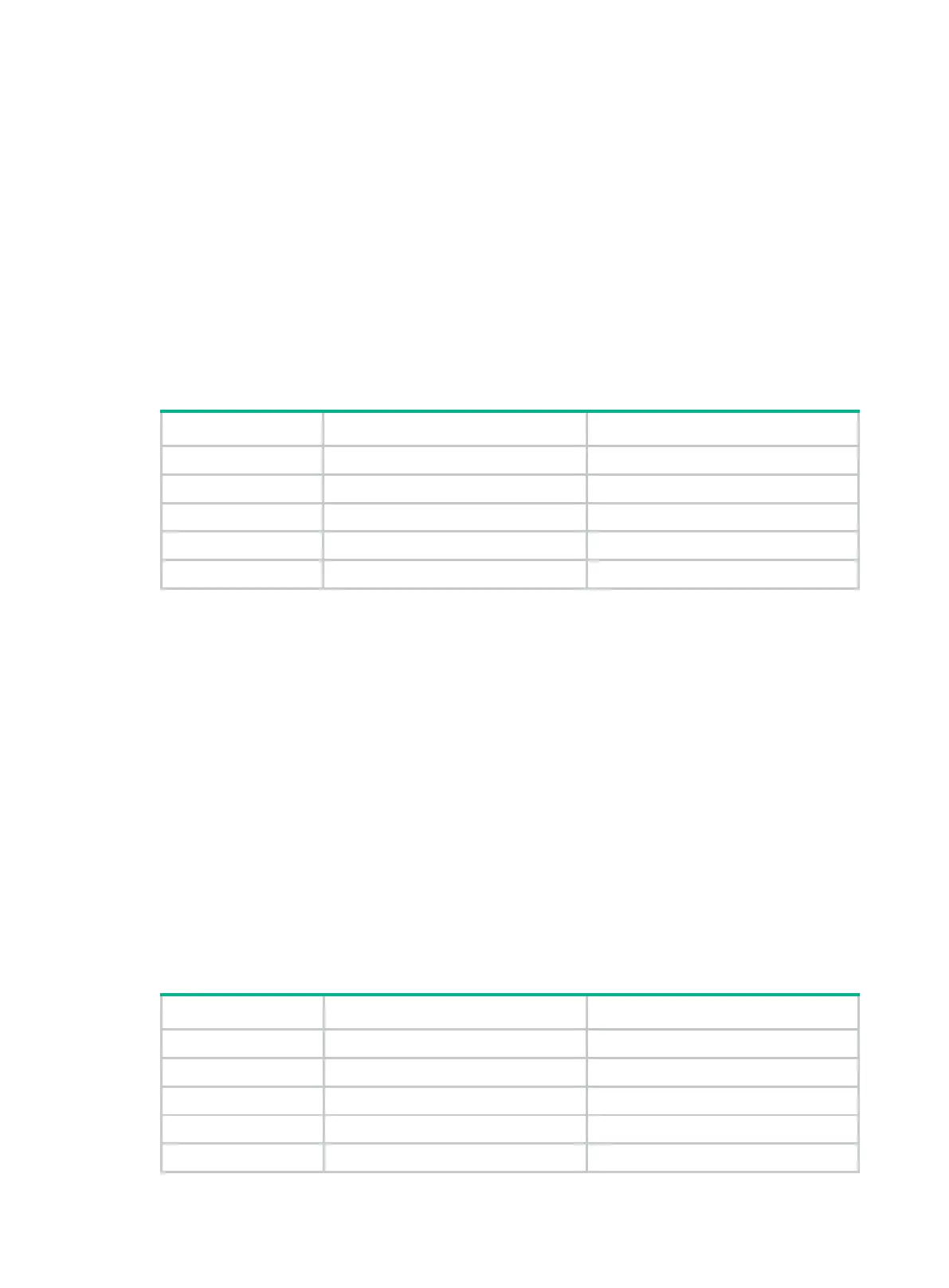

even cause device failure in the worst case. Table1-2 describes the dust concentration limits in the

equipment room.

Table1-2 Dust concentration limits in the equipment room

Substance Particle diameter Concentration limit

Dust particles ≥ 0.5 µm ≤ 3.5 × 10

6

particles/m

3

Dust particles ≥ 5 µm ≤ 3 × 10

4

particles/m

3

Dust (suspension) ≤ 75 µm ≤ 0.4 mg/m

3

Dust (sedimentation) 75 µm to 150 µm ≤ 15 mg/(m

2

h)

Sand ≥ 150 µm ≤ 300 mg/m

3

To maintain cleanliness in the equipment room, follow these guidelines:

Keep the equipment room away from pollution sources. Do not smoke, eat, or drink in the

equipment room.

Use double-layer glass in windows and seal doors and windows with dust-proof rubber strips.

Use screen doors and window screens for doors and windows open to the outside and make

sure the external windows are air tight.

Use dustproof materials for floors, walls, and ceilings and use wallpaper or matt paint that does

not produce powders.

Clean the equipment room regularly and clean the air filters of the rack each month.

Wear ESD clothing and shoe covers before entering the equipment room, keep the ESD

clothing and shoe covers clean, and change them frequently.

Corrosive gas limit

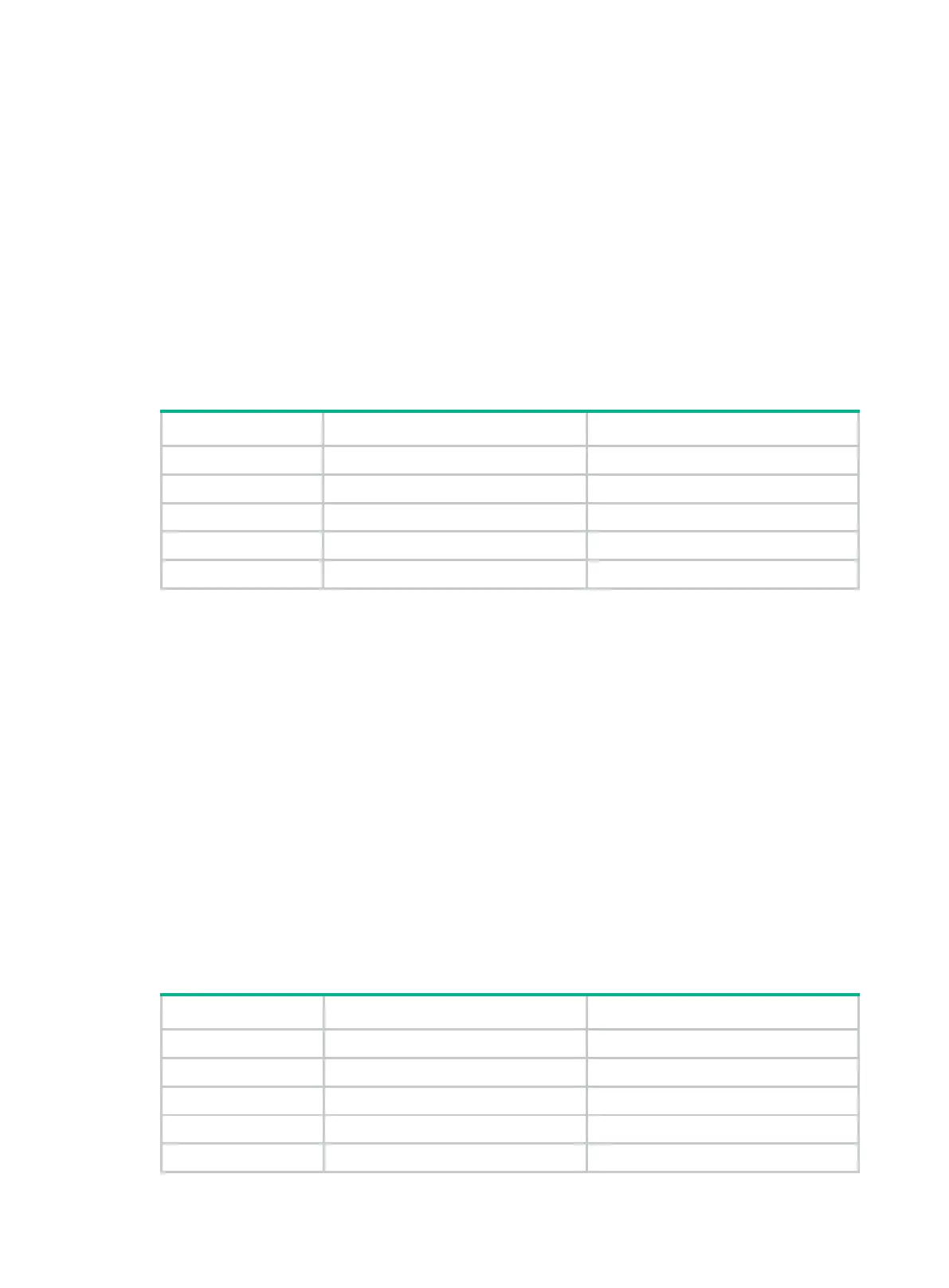

Corrosive gases can accelerate corrosion and aging of metal components. Make sure the corrosive

gases in the equipment room do not exceed the concentration limits as shown in Table1-3.

Table1-3 Corrosive gas concentration limits in the equipment room

Gas Average concentration (mg/m

3

) Maximum concentration (mg/m

3

)

SO

2

0.3 1.0

H

2

S 0.1 0.5

Cl

2

0.1 0.3

HCI 0.1 0.5

HF 0.01 0.03

Loading...

Loading...