HEIDENHAIN iTNC 530 183

5.3 Tool Compensation

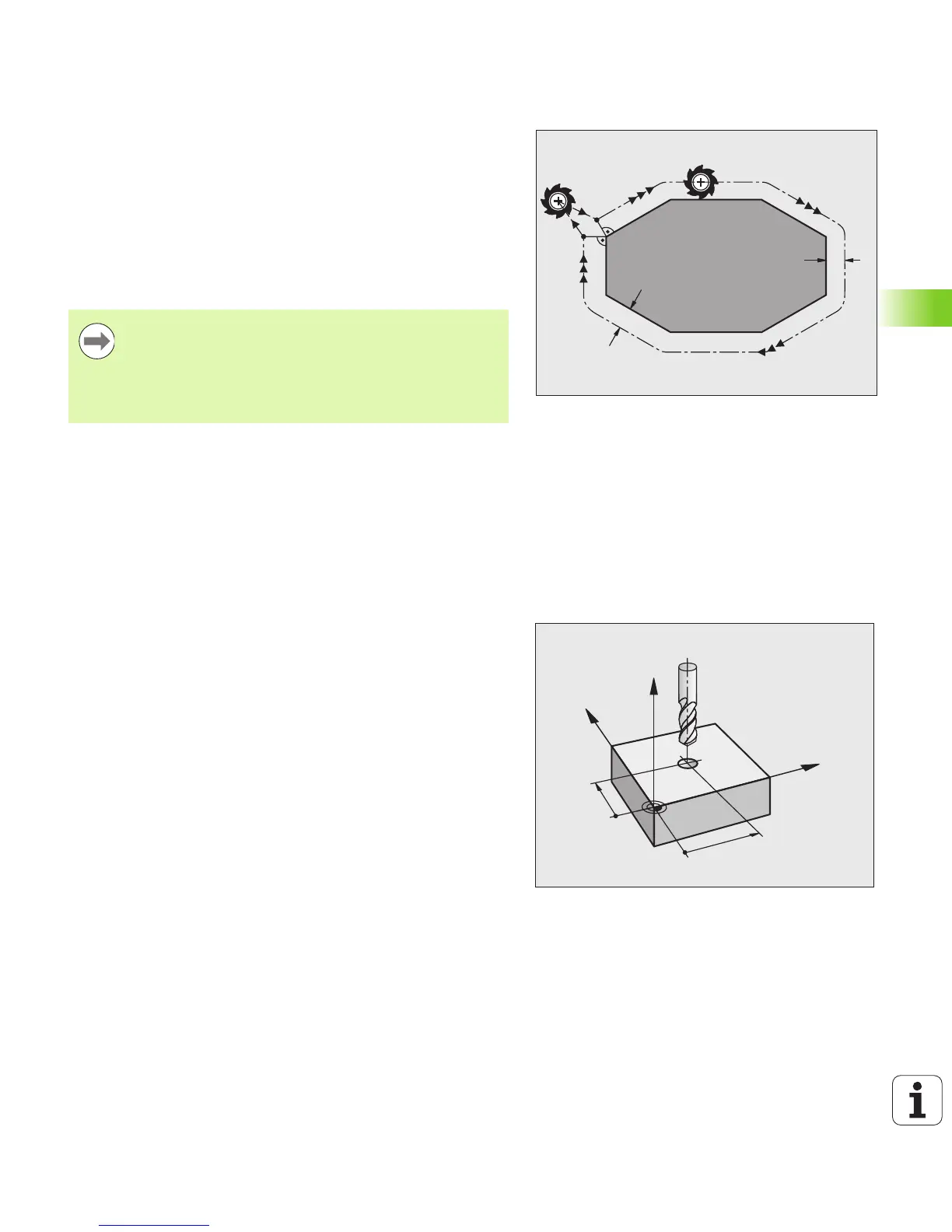

Tool radius compensation

The NC block for programming a tool movement contains:

G41 or G42 for radius compensation

G43 or G44, for radius compensation in single-axis movements

G40 if there is no radius compensation

Radius compensation becomes effective as soon as a tool is called

and is moved with a straight line block in the working plane with G41

or G42.

For radius compensation, the TNC takes the delta values from both the

T block and the tool table into account:

Compensation value = R + DR

TOOL CALL

+ DR

TAB

where

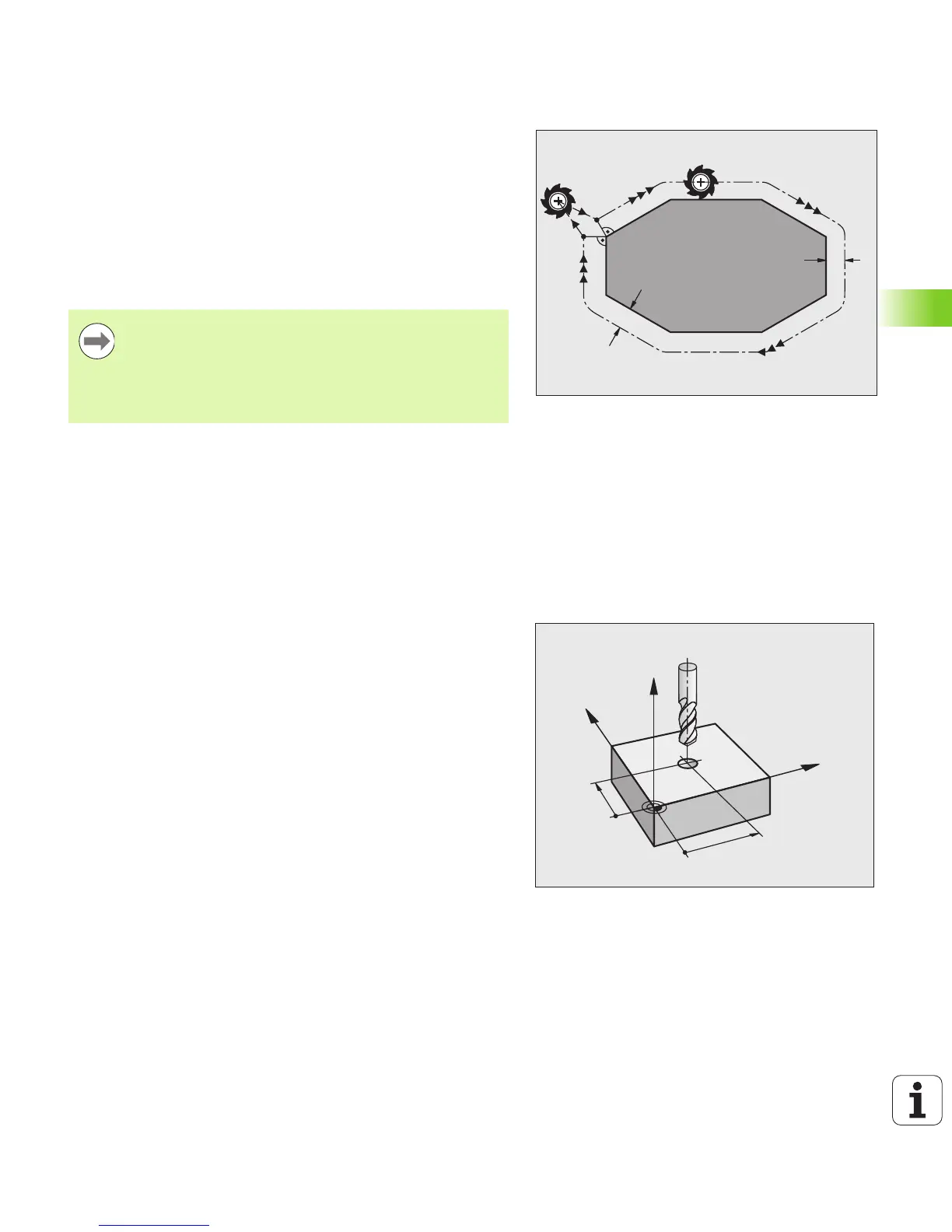

Contouring without radius compensation: G40

The tool center moves in the working plane along the programmed

path or to the programmed coordinates.

Applications: Drilling and boring, pre-positioning.

The TNC automatically cancels radius compensation if

you:

program a straight line block with G40

program a PGM CALL

select a new program with PGM MGT.

R Tool radius R from the G99 block or tool table

DR

TOOL CALL

Oversize for radius DR in the T block (not taken

into account by the position display)

DR

TAB:

Oversize for radius DR in the tool table

Loading...

Loading...