48 First Steps with the iTNC 530

1.3 Programming the First Part

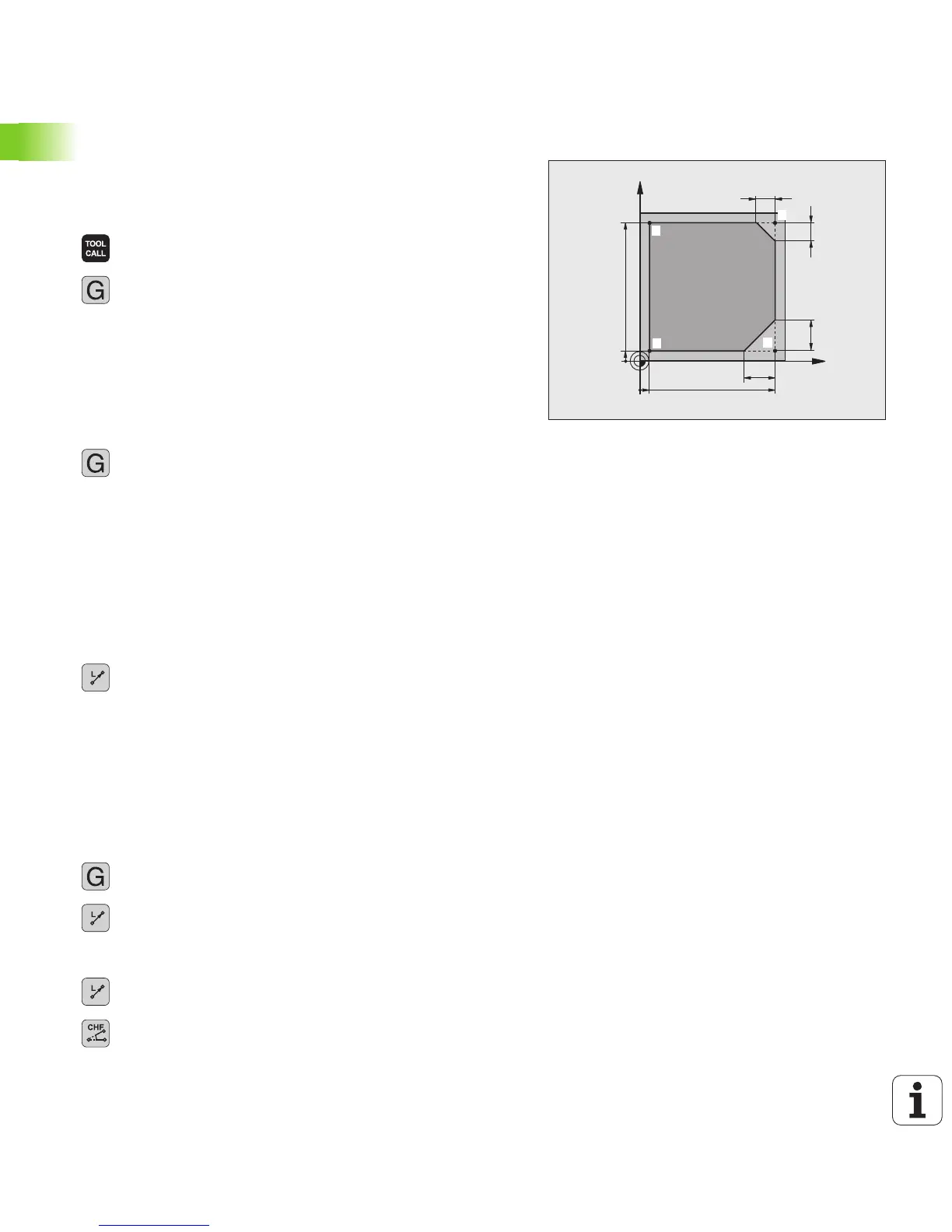

Program a simple contour

The contour shown to the right is to be milled once to a depth of 5 mm.

You have already defined the workpiece blank. After you have initiated

a dialog through a function key, enter all the data requested by the

TNC in the screen header.

U Call the tool: Enter the tool data. Confirm each of your

entries with the ENT key. Do not forget the tool axis

U Retract the tool: Press the orange axis key Z in order

to get clear in the tool axis, and enter the value for the

position to be approached, e.g. 250. Confirm with the

ENT key

U Confirm Radius comp.: RL/RR/no comp? by pressing

the ENT key: Do not activate the radius compensation

U Confirm the Miscellaneous function M? with the

END key: The TNC saves the entered positioning

block

U Preposition the tool in the working plane: Press the

orange X axis key and enter the value for the position

to be approached, e.g. -20

U Press the orange Y axis key and enter the value for the

position to be approached, e.g. -20. Confirm with the

ENT key

U Confirm Radius comp.: RL/RR/no comp? by pressing

the ENT key: Do not activate the radius compensation

U Confirm the Miscellaneous function M? with the

END key: The TNC saves the entered positioning

block

U Move the tool to workpiece depth: Press the orange Y

axis key and enter the value for the position to be

approached, e.g. -5. Confirm with the ENT key

U Confirm Radius comp.: RL/RR/no comp? by pressing

the ENT key: Do not activate the radius compensation

U Feed rate F=? Enter the positioning feed rate, e.g.

3000 mm/min and confirm with the ENT key

U Miscellaneous function M? Switch on the spindle and

coolant, e.g. M13. Confirm with the END key: The TNC

saves the entered positioning block

U Move to the contour: Define the rounding radius of

the approaching arc

U Machine the contour and move to contour point 2: You

only need to enter the information that changes. In

other words, enter only the Y coordinate 95 and save

your entry with the END key

U Move to contour point 3: Enter the X coordinate 95

and save your entry with the END key

U Define the chamfer at contour point 3: Enter the

chamfer width 10 mm and save with the END key

Loading...

Loading...