HEIDENHAIN iTNC 530 193

6.3 Contour Approach and Departure

End point

The end point should be selected so that it is:

Approachable without danger of collision

Near to the last contour point

In order to make sure the contour will not be damaged, the optimal

ending point should lie on the extended tool path for machining the

last contour element

Example

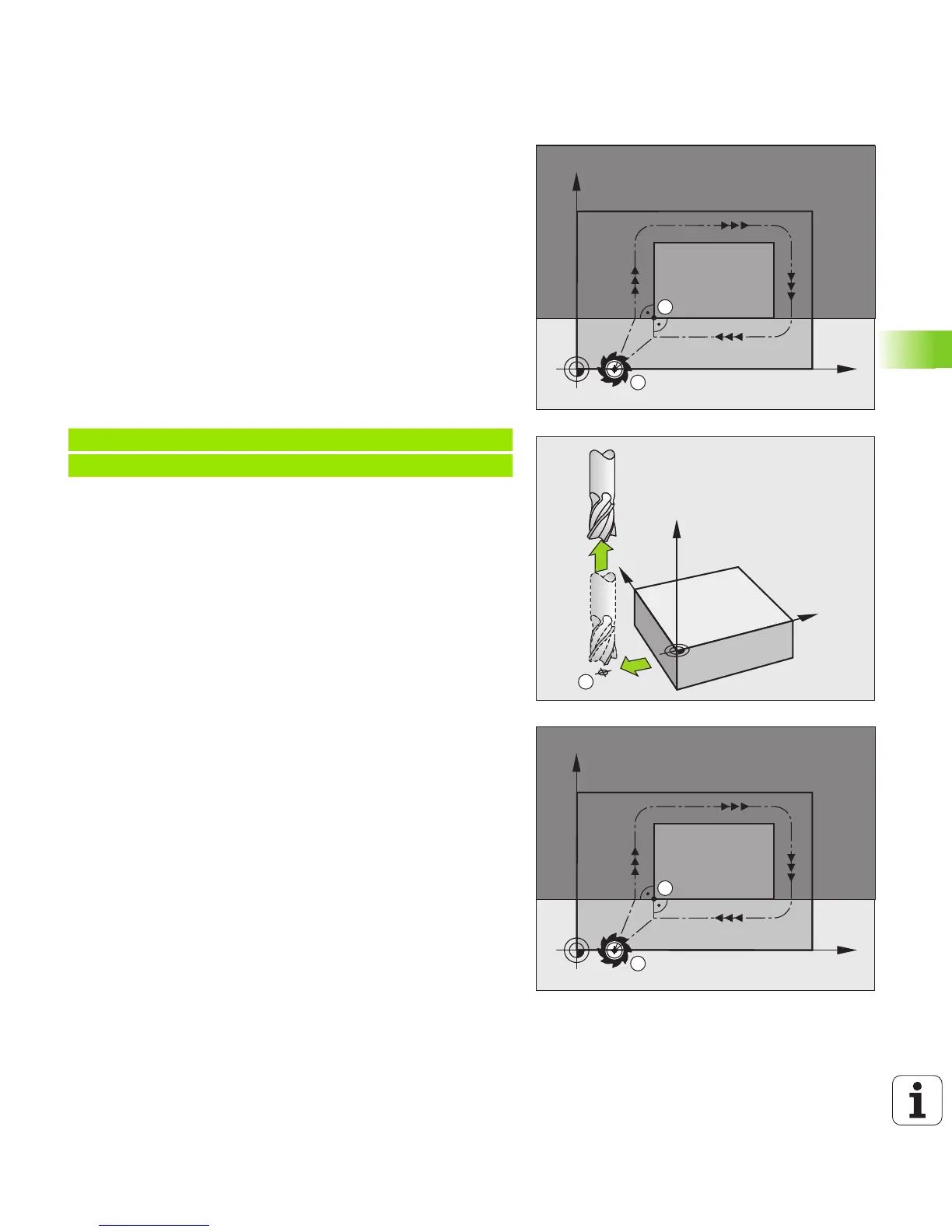

Figure at upper right: If you set the ending point in the dark gray area,

the contour will be damaged when the end point is approached.

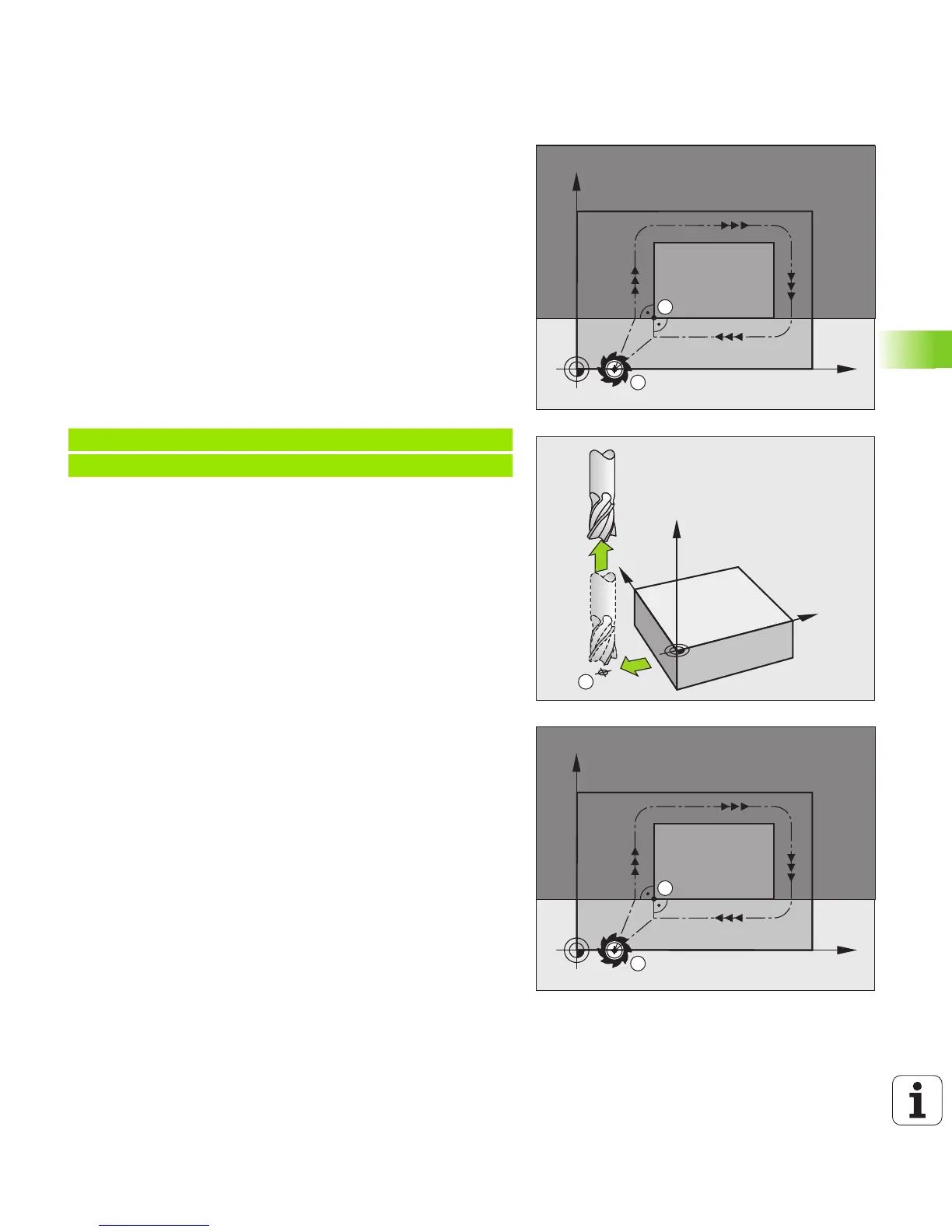

Depart the end point in the spindle axis:

Program the departure from the end point in the spindle axis

separately. See figure at center right.

Example NC blocks

Common starting and end points

Do not program any radius compensation if the starting point and end

point are the same.

In order to make sure the contour will not be damaged, the optimal

starting point should lie between the extended tool paths for

machining the first and last contour elements.

Example

Figure at upper right: If you set the starting point in the dark gray area,

the contour will be damaged when the first contour element is

approached.

Loading...

Loading...