HEIDENHAIN iTNC 530 415

12.5 Peripheral milling: 3-D radius compensation with workpiece orientation

12.5 Peripheral milling: 3-D radius

compensation with workpiece

orientation

Function

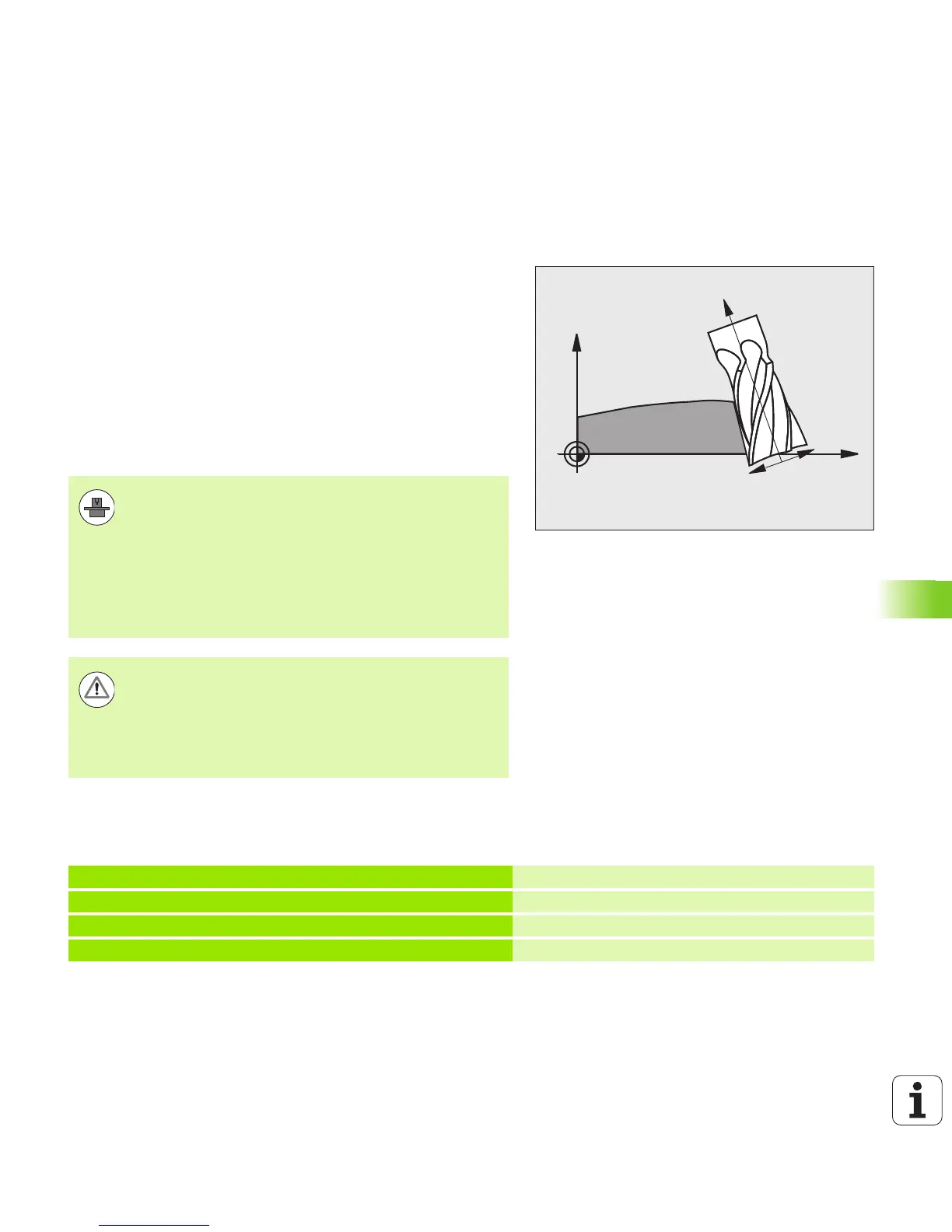

With peripheral milling, the TNC displaces the tool perpendicular to the

direction of movement and perpendicular to the tool direction by the

sum of the delta values DR (tool table and T block). Determine the

compensation direction with radius compensation G41/G42 (see figure

at upper right, traverse direction Y+).

For the TNC to be able to reach the set tool orientation, you need to

activate the function M128 (see “Maintaining the position of the tool tip

when positioning with tilted axes (TCPM): M128 (software option 2)”

on page 410) and subsequently the tool radius compensation. The

TNC then positions the rotary axes automatically so that the tool can

reach the orientation defined by the coordinates of the rotary axes

with the active compensation.

You can define the tool orientation in a G01 block as described below.

Example: Definition of the tool orientation with M128 and the

coordinates of the rotary axes

This function is possible only on machines for which you

can define spatial angles for the tilting axis configuration.

Refer to your machine tool manual.

The TNC is not able to automatically position the rotary

axes on all machines. Refer to your machine manual.

Note that the TNC makes a compensating movement by

the defined delta values. The tool radius R defined in the

tool table has no effect on the compensation.

Danger of collision!

On machines whose rotary axes only allow limited

traverse, sometimes automatic positioning can require

the table to be rotated by 180°. In this case, make sure

that the tool head does not collide with the workpiece or

the clamps.

N10 G00 G90 X-20 Y+0 Z+0 B+0 C+0 *

Pre-position

N20 M128 *

Activate M128

N30 G01 G42 X+0 Y+0 Z+0 B+0 C+0 F1000 *

Activate radius compensation

N40 X+50 Y+0 Z+0 B-30 C+0 *

Position rotary axis (tool orientation)

Loading...

Loading...