3.4 Checking Measured Values

39

3

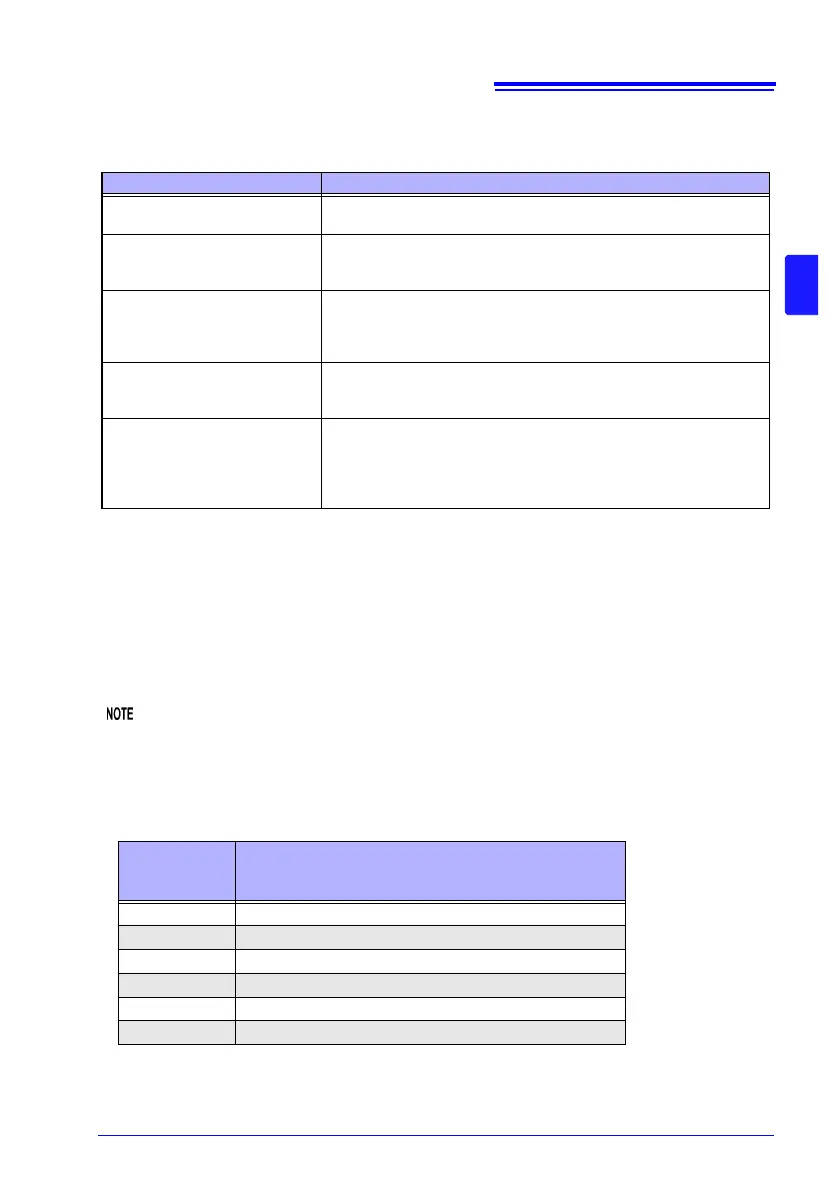

*1 Over-range Detection Function

Examples of Over-range Faults

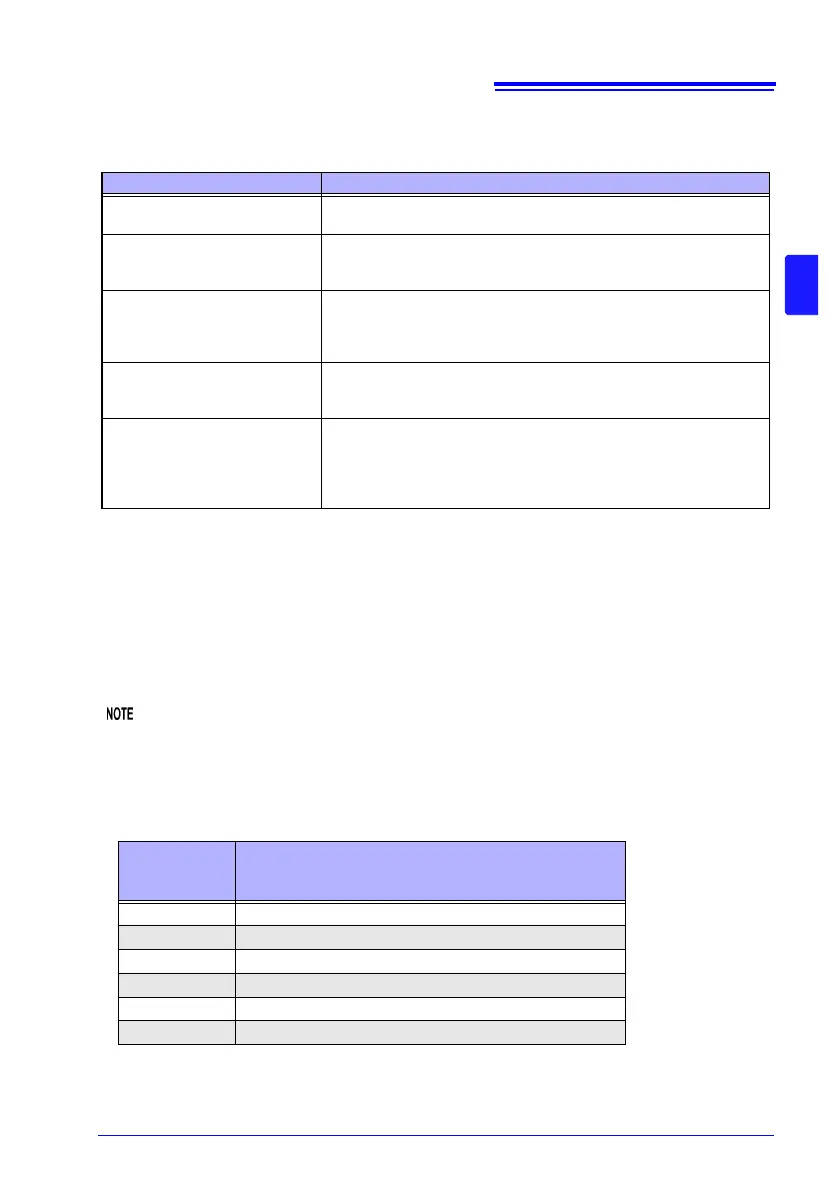

*2 Current Fault Detection Function

Example of Current Fault

• SOURCE A or SOURCE B probe open

• Broken measurement target (open work)

• SOURCE A or SOURCE B cable break, poor connection

• SOURCE wiring resistance in excess of the following values may cause a current fault,

making measurement impossible. When using measurement current 300 mA ranges,

keep the wiring resistance as well as the contact resistance between the measurement

target and measurement lead low.

• If a measurement is performed using a high-resistance range, it will take time after the

probes are actually open until a constant current error occurs.

Example:300 k range 20 ms

3 M range 250 ms

Over-range Detection Measurement Example

The measured value is outside of

the measurement range.

Attempting to measure 40 m with the 30 m range selected

The relative tolerance (%) display

of the measured value exceeds

the display range (999.99%).

Measuring 500 (+2400%) with a reference value of 20

The zero-adjusted value is out-

side of the display range.

Performing zero-adjustment after connecting 50 m with the 300 m

range

Measuring 10 m yields a -40 m reading, exceeding the display

range.

While measuring, input voltage

exceed the A/D converter input

range.

Measuring a large resistance value in an electrically noisy environment

Current did not flow normally to

the measurement target.

(When the current fault mode set-

ting is set to “Over-range output”

only)

When the measurement target yields an open FAIL result

When either the SOURCE A or SOURCE B terminal suffers from poor

contact.

*To display “- - - - -” when a current fault occurs, set the current fault

mode setting to “Current fault.”(p.40)

(Reference value)

Range

Wiring resistance and contact resistance

(Resistance value between SOURCE B and SOURCE A,

excluding measurement target)

30 m, 300 m 2

3 70

30 100

300 2 k

3 k 700

30 k to 3 M 2 k

Loading...

Loading...