21

3. OPERATING PROCEDURE [How to Use the Liquid Crystal Display (LCD)]

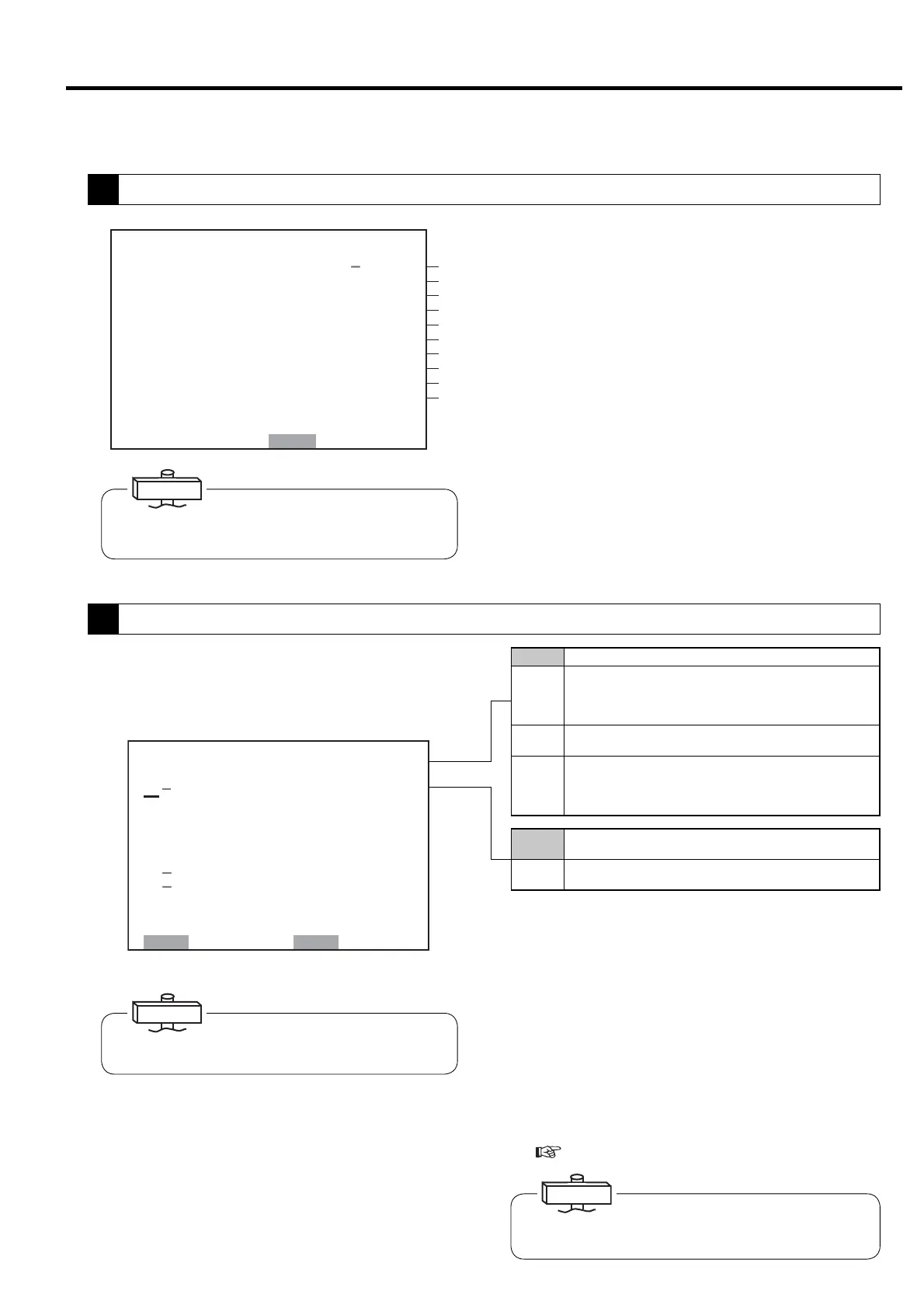

3.3.5 [FUNCTION MENU] - Setting Displays

Confirm the settings by lead/lag and multi unit

control (option). These options need wiring

modification. Item number with a dash “-“ cannot be

selected on LCD monitor.

1- MODE:

Operation mode set on the digital monitor.

2. DUAL TIME: Alternate operation hours of lead/

lag operation.(Setting range : 0.1 to 99.9 hours;

initial value: 8.0)

3. METHOD: Switching method (overlap or interval)

of lead/lag operation.

4. SWITCHOVER: Switching-over or overlapping

period of lead/lag operation. (Setting range : 5 to

300 seconds; initial value: 15)

㼇㻹㼁㻸㼀㻵㻙㼁㻌㻿㻱㼀㼀㻵㻺㻳㼉

㻝

㻹㻻㻰 㻱 䠖 㻳㻸

㻞䠊㻰㼁㻭㻸 㻌 㼀 㻵㻹㻱䠖 㻌 㻤䠊

㻌㻿㻺

㻜㼔

㻟䠊㻹㻱㼀㻴㻻㻰䠖 㻭㻼

㻠䠊㻿㼃㻵㼀㻯㻴㻻㼂㻱㻾䠖 㻜㻝㻡㼟

㻡䠊㻮㻭㻯㻷㼁㻼䠖 㻌 㻌 㻌 㻣㼜

㻻㼂㻾㻾㻸

㼟㼕

㻢䠊㼁㻺㻸㻻㻭㻰䠖 㻌 㻌 㻌 㻟㼜 㼟 㼕

㻣

㻭㻸㼀䠊㼀 㻵㻹㻱䠖㻌 㻠㻤㻜㻹㻵 㻺

㻤

㻯㻻㻺㼀㻾㻻㻸 㻹㻻㻰㻱 䠖 㻮

㻿㻱㼀䠖㻿㼀㻻㻾㻱 㻌㻹㻻㻺䠖㻮㻭㻯㻷

①

②

③

④

⑤

⑥

⑦

⑧

⑨

⑩

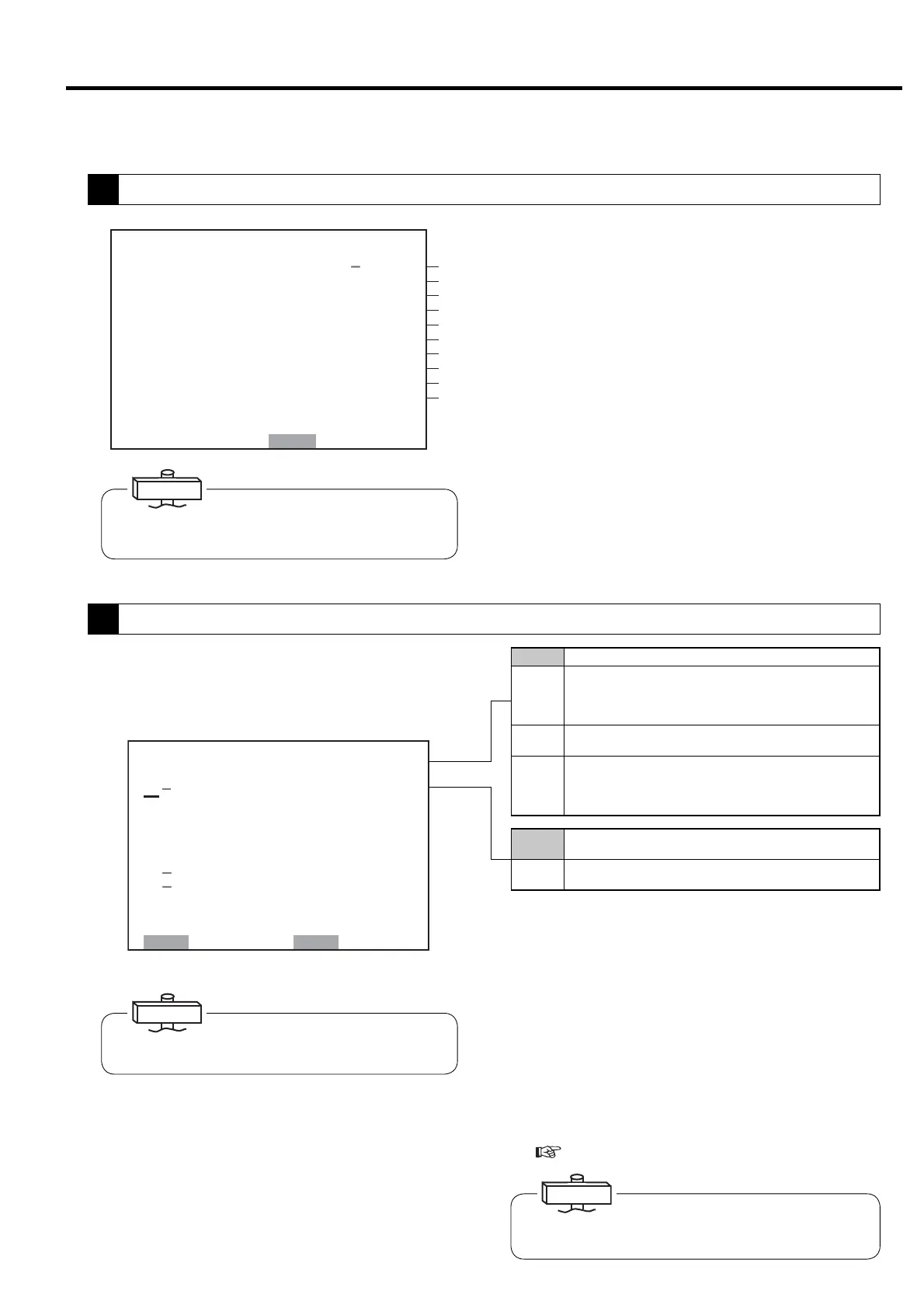

㼇㻮㻭㻿㻵㻯 㻿㻱㼀㼁㻼㼉

㼂㻱㻾䠊䠖 㻡䠊㻜

㻡䠊㻜

㻿㻱㻾 㻵 㻱㻿 㻺㻭㻹㻱䠖 㻰㻿㻼

㻯㻻㻻㻸 㻵 㻺㻳 㻹㻱 㼀㻴㻻㻰 䠖 㼃㼀 㻾

㻺㻻䠊㻻㻲 㻿㼀㻭㻳㻱 䠖 㻌 㻞

㻼㻙㻿㻼㻱㻯䠖 䚷㻝 㻜㻜㼜㼟 㼕

㻼䠊㻰㻭㼀㻭䠖 䚷䚷 㻢㻤 㼜 㼟 㼕

䠟䠰 䠖 㻞 㻡 㻜䠝

㻯㻸㼀䠊㻰㻱㻸㻭㼅䠖 㻌 㻡 㼟

㻵㻼㻵䠖 㻵 㻵 㻵

㻭㻰㻾㻱㻿㻿 㻺㻻䠊䠖 㻌 㻝

㻹㻻㻺 䠖 㻮㻭㻯㻷

If using the backup function, switch to the digital

monitor for setting.

When contacting the local Hitachi distributor, inform

this information as a based setting status.

IMPORTANT

IMPORTANT

1

Model Setting Confirmation

2

Operation Mode Setting

This display contains software version (VER.), air

compressor series (SERIES NAME), cooling method

(COOLING METHOD), number of air compression

stages (NO. OF STAGE), action against instantaneous

power interruption (IPI) and etc. “** ” means the

setting that is not required.

① Indicates board software version.

② Indicates compressor type.

③ Displays cooling type.

④ Displays the number of compressor stages.

⑤ Displays pressure specification.

⑥ Displays interstage pressure.

⑦ Indicates CT setting value.

⑧ Displays water failure detection conditions for water

cooled compressor.

⑨ Displays status of instantaneous power interruption

(IPI) restart setting.

⑩

Displays compressor number. (Must be distinguished

by number is using communication function.)

The settings can be memorized while the air compressor

is stopped.

IMPORTANT

5. BACKUP: Pressure to start a backup unit in a

backup operation (cut-in (load) pressure – α)

6. UNLOAD: Pressure to unload both the units in a

backup operation (cut-out (unload) pressure – α)

7- ALT. TIME: Displays time remaining until switch for

dual / backup operation. Time is not counted down

when operating 2 units for backup operation. When

operation is stopped, remaining time is maintained.

8- CONTROL MODE: Control mode A or B for Vtype

(

3.3.2). “**” is indicated in fixed speed type.

SNGL Operates an air compressor independently

STPR

Operates by multi roller EX of exclusive use for NEXT

series using communication function.

By this setting RS485 communication port is effective.

The setting of air compressor number is required.

DUAL

Operates two air compressors alternately according to

a time schedule. The AUTO light comes ON (glowing).

BKUP

Operates two air compressors according to a preset

back up pressure. Starts the back up slave unit when

the pressure has dropped to the desired preset back up

pressure. The AUTO light comes ON (glowing)

OVERLAP

Slave unit starts, master/slave units overlap in operation

for a preset period, and then master unit stops.

INTERVAL

Master unit stops, a non-operating interval passes, and

then slave unit starts.

Loading...

Loading...