9. MAINTENANCE [How to Service the Air Compressor]

92

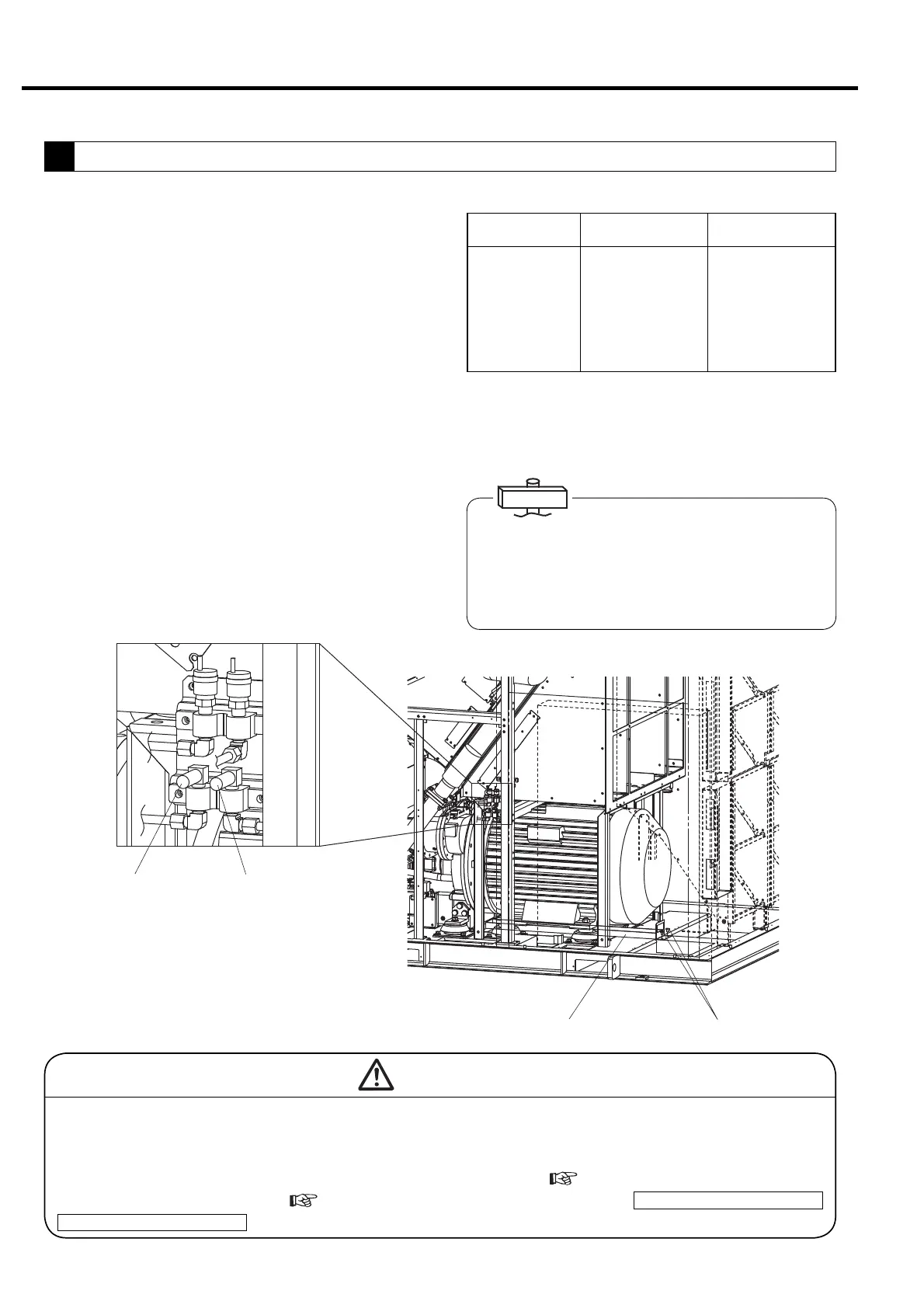

Load-side bearing

Grease port

Anti-Load-Side bearing

Grease port

Grease pan Bolt with knob

Grease filling amount

Model Load-Side bearing

Anti-Load Side

bearing

DSP-90A6N

DSP-90W6N

DSP-90VA6N

DSP-90VW6N

DSP-110A6N

DSP-110W6N

DSP-110VA6N

DSP-110VW6N

1.2oz

(30g)

2.5oz

(70g)

● Example of grease gun

Lever-type grease gun CH-400 Micro-Hose (pin type

SPK-1C) by Yamada Corporation.

Feed the main motor with grease in accordance with the

Grease Filling Amount table. Grease to be used is Raremax

Super by Kyodo Yushi (Hitachi part name: RMS grease)

(P/N 455).

① Open the front door. Grease the specified amount

through the grease port using a grease gun.

②

Check the grease pan, and clean the pan as necessary.

③ Close the front door.

Be cautious of replenishing grease more than the spcified amont. It may cause leaking of grease and/or

malfunction of the protective device due to overheat of the bearing. Grease at once during start-up

commissioning.

Periodically replace the main motor bearing in accordance with

“9.1 Periodical Maintenance of

Compressor” in page 74 and

“9.2 Standard Maintenance Schedule”

Maintenance Schedule A

Maintenance Schedule B

in pages 75 to 78.

CAUTION

● Contact the local HITACHI distributor/master dealer or

representative office for the grease detail.

● Greasing must be done while the main motor

operating.

● Cleaning of grease pan must be done while the air

compressor stops.

IMPORTANT

14

Main Motor Greasing

Loading...

Loading...