10 Troubleshooting

Troubleshooting in check mode

SMGB0136 rev.0 - 07/2021

301

10

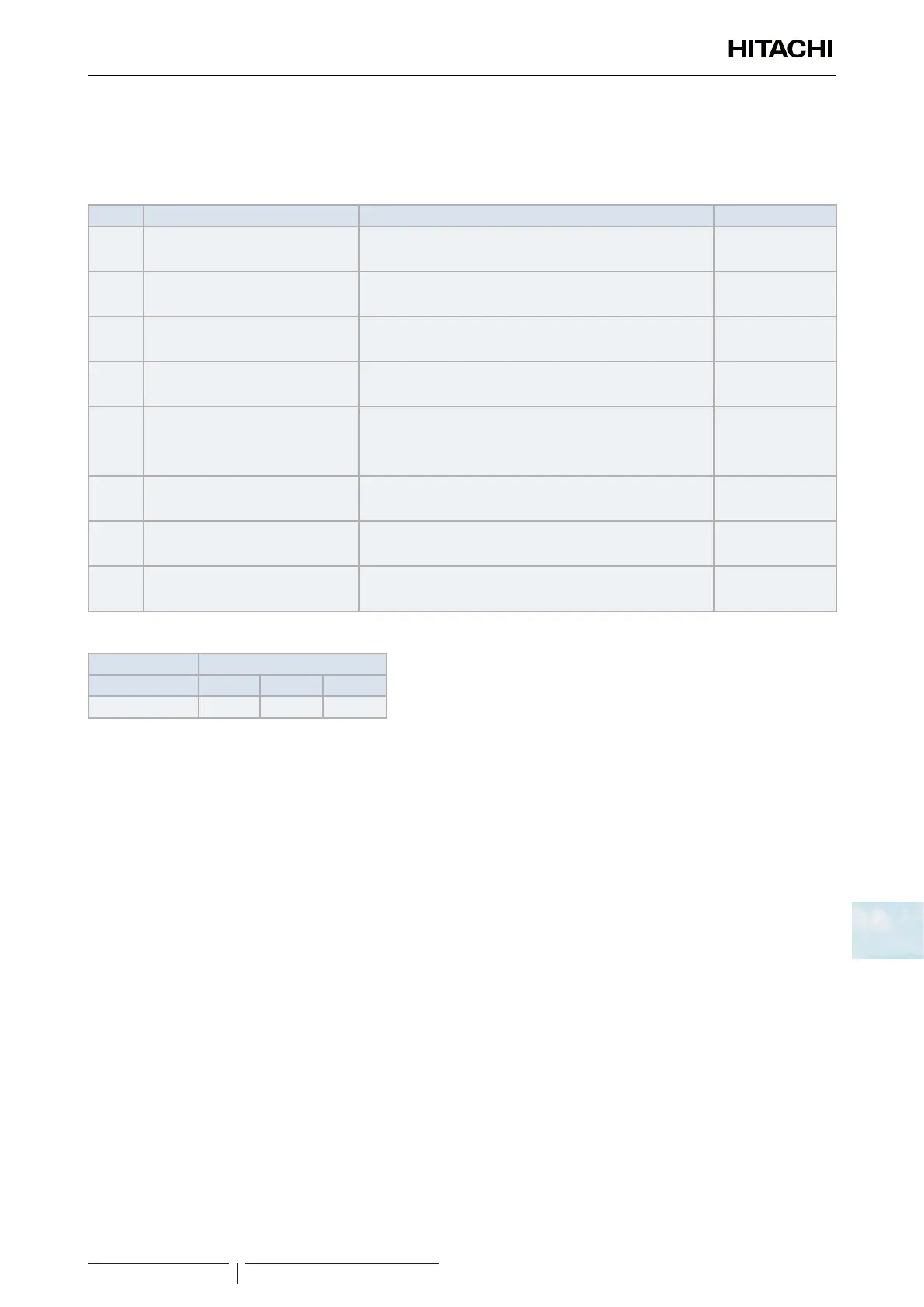

Activating condition of protection control code

To monitor the conditions such as the temperature change and others, the control of the frequency and other controls are

performed by the protection control in order to prevent the abnormal operations. The activating conditions of protection

control are shown in the table below:

Code Protection Control Activating Condition Remarks

P0

Low-Pressure Ratio Control at

Cooling Operation

IfCompressionRatioεexceedsathresholdvalue

=> Frequency Increase

—

P1

High-Pressure Ratio Control at

Heating Operation

IfCompressionRatioεislowerthanathresholdvalue

=> Frequency Decrease

—

P2

High-Pressure Increase Protection

High Pressure Switch for Control is activated

=> Frequency Decrease

—

P3

Over Current Protection

Inverter Output Current > (*1)A

=> Frequency Decrease

—

P4

Inverter Temperature Increase

Protection

Inverter Fin Temperature

RAS-3HVRC2≥70ºC

=> Frequency Decrease

—

P5

Discharge Gas Temperature

Increase Protection

Temperature at the top of compressor is high

=> Frequency Decrease

—

P9

Unbalance Power Source Detecting

Inverter Output Current exceeds a threshold value

=> Frequency Decrease

—

PA

Current Demand Control

Inverter Output Current exceeds a threshold value

=> Frequency Decrease

In case of Demand

Control Setting

(1*)

Connection 220-240V

HP 2 2.5 3

Current (A) 10.5 10.5 10.5

10.3.2 RAS-(4-6)H(V)(R/N)(C/P)2E

10.3.2.1 Troubleshooting by using the 7-segment display

? NOTE

Only the authorized person can carry out checks using this method.

The operating conditions and each part of the refrigerant cycle can be checked with the 7-segment display and push

switches on the PCB1 (models RAS-(4-6)HV(R/N)(C/P)2E and PCB2 (models RAS-(4-6)H(R/N)(C/P)2E) in the outdoor

unit.

Before carrying out checks

1 Turn ON the main power supply switch. Wait more than 20 seconds before starting the checks.

2 Check items:

- Information of the outdoor unit.

- Information of the indoor unit and ombined indoor units number.

- Expansion valve opening.

- Temperature at each part, etc.

- Information of the cause of the alarm code.

- Alarm code historical information.

3 Check the location of the 7-segment display and the push switches.

! DANGER

AC220-240V is applied to the PCB and electrical parts. Never touch the electrical parts and the cables when carrying out the

checks.

Loading...

Loading...