11 Maintenance notes

Refrigerant collection method

SMGB0136 rev.0 - 07/2021

334

11.6 Refrigerant collection method

11.6.1 Refrigerant collection method when replacing the parts of outdoor unit

Process

No.

Procedure Remarks

1 Turn OFF the main switch of the outdoor unit. -

2

Remove the covers, the thermistor, the crankcase heater, the

power wirings, and other items.

Make sure that the terminal part of the detached power

supply wires is not exposed by the winding insulation

tape and other items.

3

Attach the manifold to the check joint of the high pressure side

and the low pressure side of the outdoor unit.

-

4 Turn ON the main switch of the outdoor unit. -

5

In case that compressor operates

Perform pre-refrigerant collection during cooling test run.

• Start the test run:

- Turn ON the dip switch of outdoor unit:

3HP 1ph = PCB - DSW301 pin1

4-6HP 1ph = PCB2 - DSW1 pin1 → ON

4-6HP 3ph = PCB1 - DSW1 pin1 → ON

• The test run should be performed for approx. 10 min, (until

Ps>0.3 MPa, Td>75 °C)

• Check the suction pressure “Ps” on 7-segments display of

outdoor unit.

• Close the gas valve inmediately. When Ps is ≤0.2 MPa

perform the forced stoppage by turning on the dip switch:

3HP 1ph = PCB - DSW301 pin4 → ON

4-6HP 1ph = PCB2 - DSW1 pin4 → ON

4-6HP 3ph = PCB1 - DSW1 pin4 → ON

• Cancel cooling operation:

3HP 1ph = PCB - DSW301 pin1 → OFF

4-6HP 1ph = PCB2 - DSW1 pin1 → OFF

4-6HP 3ph = PCB1 - DSW1 pin1 → OFF

• Cancel the forced stoppage:

3HP 1ph = PCB - DSW301 pin4 → OFF

4-6HP 1ph = PCB2 - DSW1 pin4 → OFF

4-6HP 3ph = PCB1 - DSW1 pin4 → OFF

In case that compressor does not operate

• Close all the gas stop valves (at low and high pressure

sides).

After closing the gas stop valve, the decrease of Ps value

is fast. To guarantee the reliability of the compressor.,

make sure that the decrease does not reach Ps<0.1 MPa

when performing the forced stoppage.

The operation may nished when any of the conditions 1)

to 3) occus:

1 Ten minutes have passed and STP is displayed in

7-segments.

2 “08” is displayed in 7-segments.

3 When Ps<0.1 MPa is continued for one minute in

ten minutes STP is displayed in 7-segments and the

operation nishes.

6 Close the liquid stop valve completely.

To avoid the spillage of all the refrigerant if the check

valve is broken.

7

Check for a leakage of the check valve on the discharge gas

side:

• Enforced stoppage of the compressor → ON so that the

compressor will not run although the running command is

sent from the remote control switch.

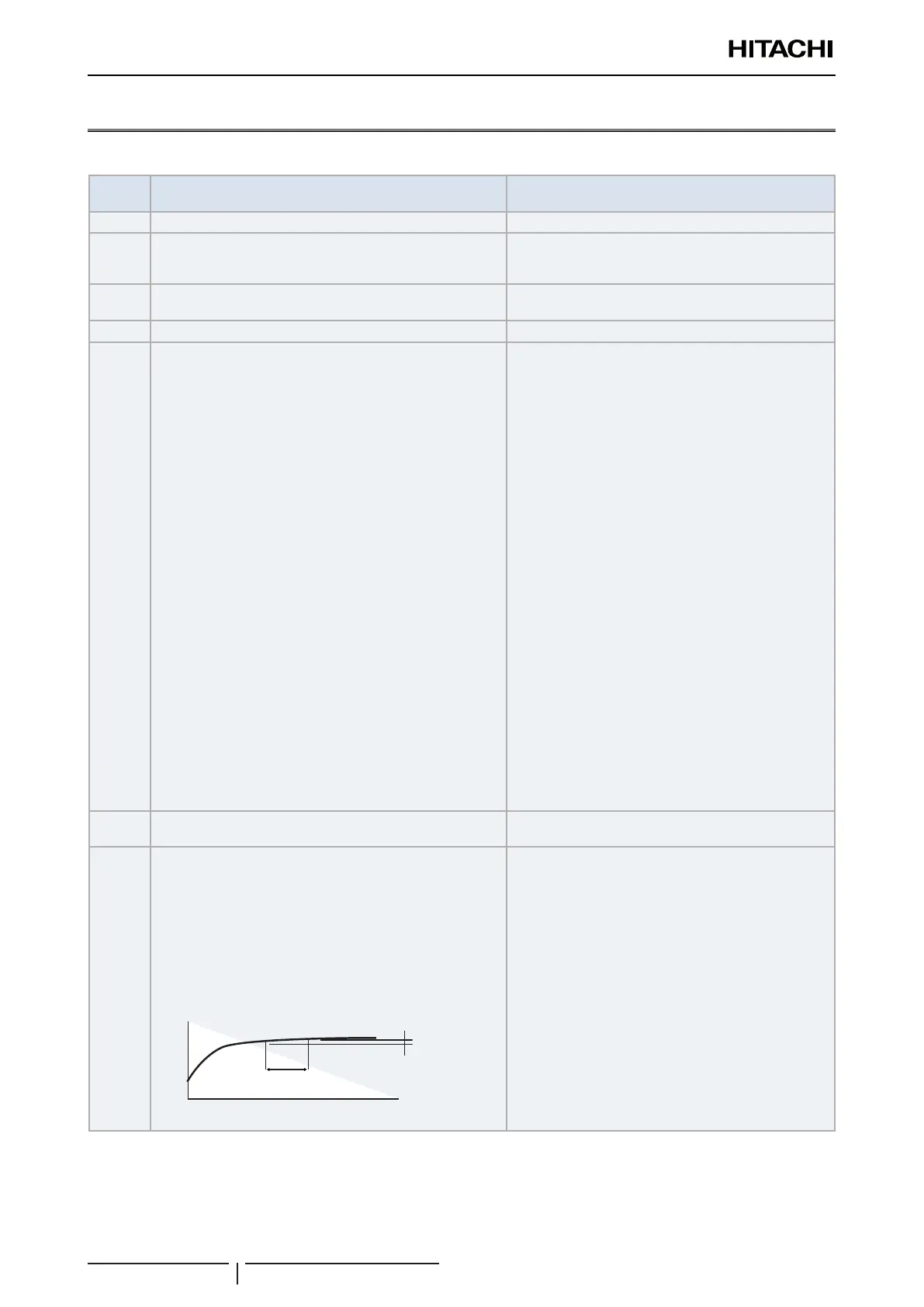

• Check that variation of Ps on the outdoor unit PCB is

17 seconds. Make sure that the Ps increase is within

0.03 MPa in two minutes after the Ps increase at the

stoppage (during approximately ve minutes). Also make

sure that Pd > Ps.

0.03 MPa

or smaller

2 minutes

Time

Ps

When you stop the compressor for replacing:

• You can check the leakage of the check valve by

means of the Ps variation because the SVA opens

so that the discharge gas side of the inverter

compressor can connect to the low pressure side.

• 0.03 MPa/2 minutes is within the permissible limits

for the check valve on the discharge gas side.

• The leakage of the check valve may cause an

incorrect brazing due to the gas pressure at the

brazing of the discharge piping.

• If the compressor-replacing mode is performed again

set the DSW4-4 to OFF and keep the DSW4-4 at the

OFF side during ten minutes. Then start according to

the procedure No. 6.

Loading...

Loading...