EasyBalancer EB 3500 Vibration testing and balancing device - Setup instructions

3 - 15

3.7.8 Calibration

Calibration with two (or three) identical weights

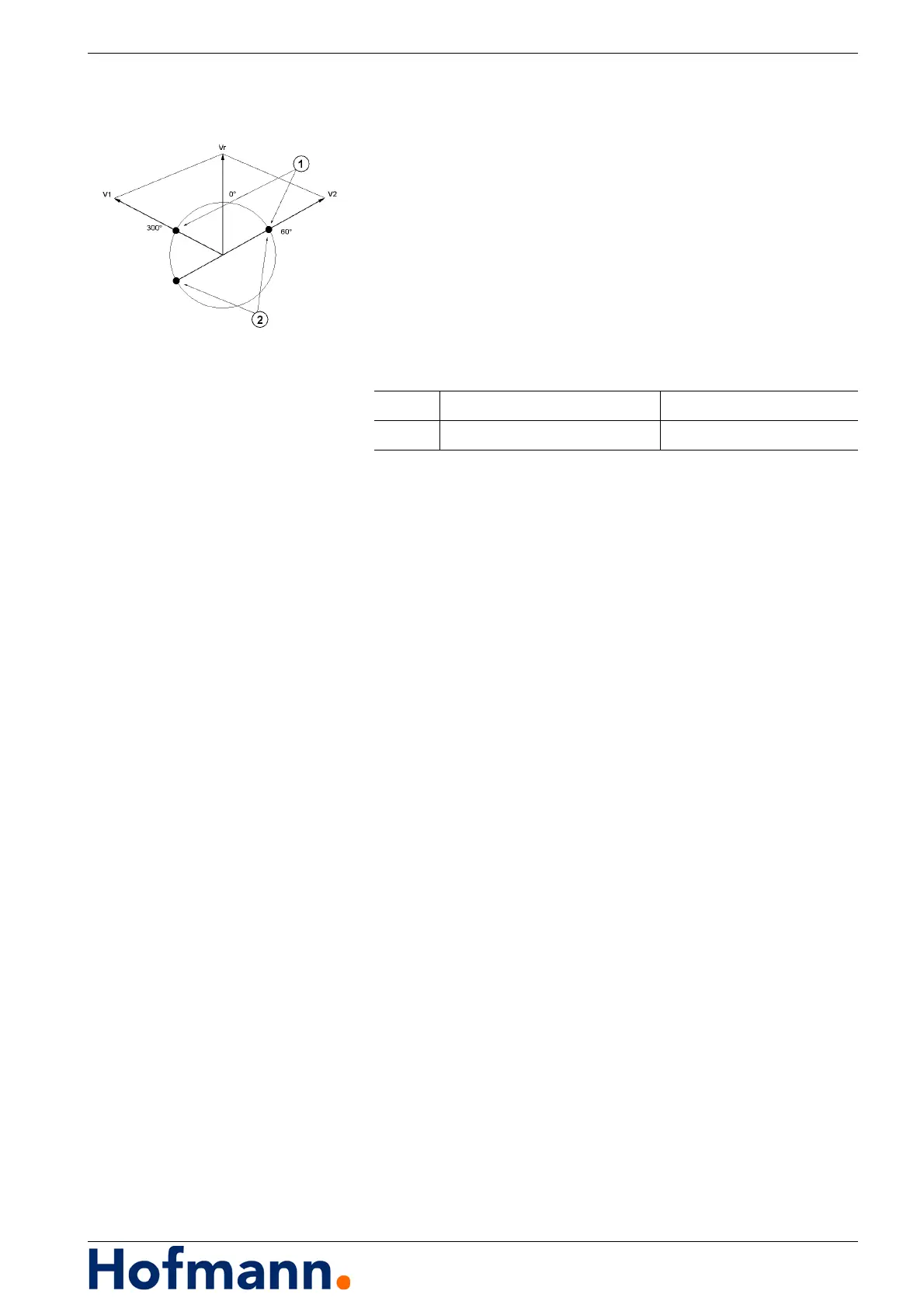

The spread angle method is used to correct the unbalance on

grinding wheels, for example. The two weights are adjusted

during the calibration from the positions 240° (V1) / 60° (V2)

to 300° (V1) / 60° (V2).

Vectorial (geometric) addition of the two vectors V1 and V2

produces the calibration vector Vr.

The magnitude of the vector Vr is the same as one of the two

weights. The position of the resulting vector Vr is at 0°.

At

= 300° and

= 60°, Vr = V1 = V2.

The two sliding weights must be identical.

3.7.9 Permissible vibration severities

When balancing in production, the balancing tolerances

are generally specified in accordance with DIN ISO 1940-1.

For operational balancing, permissible vibration severities are de-

fined, for example, in DIN ISO 20816-1 (see chapter Evaluation –

Overall value measurement).

Operational balancing is often performed up to the resolution limit

of the balancing equipment. Relatively large fluctuations in the

vibration value then occur during the subsequent control run.

In order to exclude erroneous results, a test weight can be attached

.

This must then be correctly displayed according to size and an-

gular position. The test weight should be removed afterwards.

The residual unbalance displayed after the last control run can

be used to calculate the achieved balancing quality according to

DIN ISO 1940-1.

1 Calibration position Vr = V1 = V2

2 Neutral position Vr = V1 + V2 = 0

Loading...

Loading...