EasyBalancer EB 3500 Evaluation - Assessment of roller bearing condition

10 - 7

10.3 Assessment of roller bearing condition

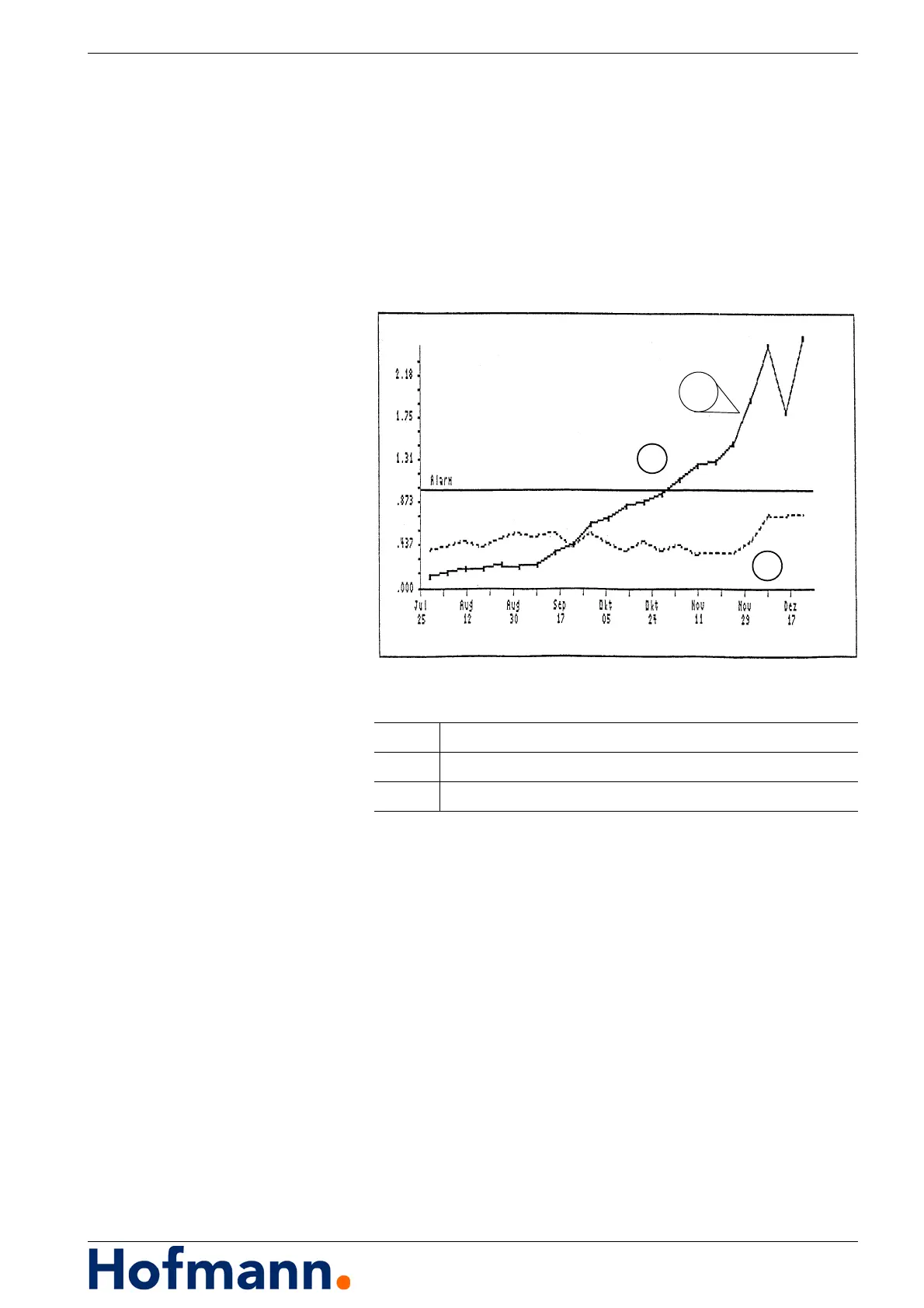

Experience shows that the development of roller bearing damage

on machines running in continuous operation takes several months.

A measuring cycle of two weeks is therefore recommended for

the timely detection of such damage development with the aid of

trend monitoring. However, other cycles, e.g. one week or four

weeks, are also possible. The accuracy of roller bearing damage

is increased if the measurement is started on a new bearing.

The damage phase is reached when the measured values have

increased by a factor of 10 to 20.

Fig. 10-19: Trend of overall vibration and gSP value on a pump bearing; bearing

damage at the beginning of December.

To measure the gSP value, it is recommended to press the

HMA 1130/1140 acceleration sensor onto the measuring point

using a probe tip. The values determined in this way generally do

not agree with measured values obtained by screwing on or fixing

with a magnetic base. This is due to the different transmission

mechanisms of the vibrations in the kHz range with the different

sensor mountings. Nevertheless, measurements with accelera-

tion sensors attached directly to the measuring point can also be

used if the same measuring conditions are repeatedly maintained

and a trend observation is carried out.

1 Bearing damage

2 Spike energy

3 Vibration velocity

Loading...

Loading...