EasyBalancer EB 3500 Evaluation - Interpretation of vibration measurements

10 - 9

10.4 Interpretation of vibration measurements

Possible cause Comment Appearance Confirmation of cause

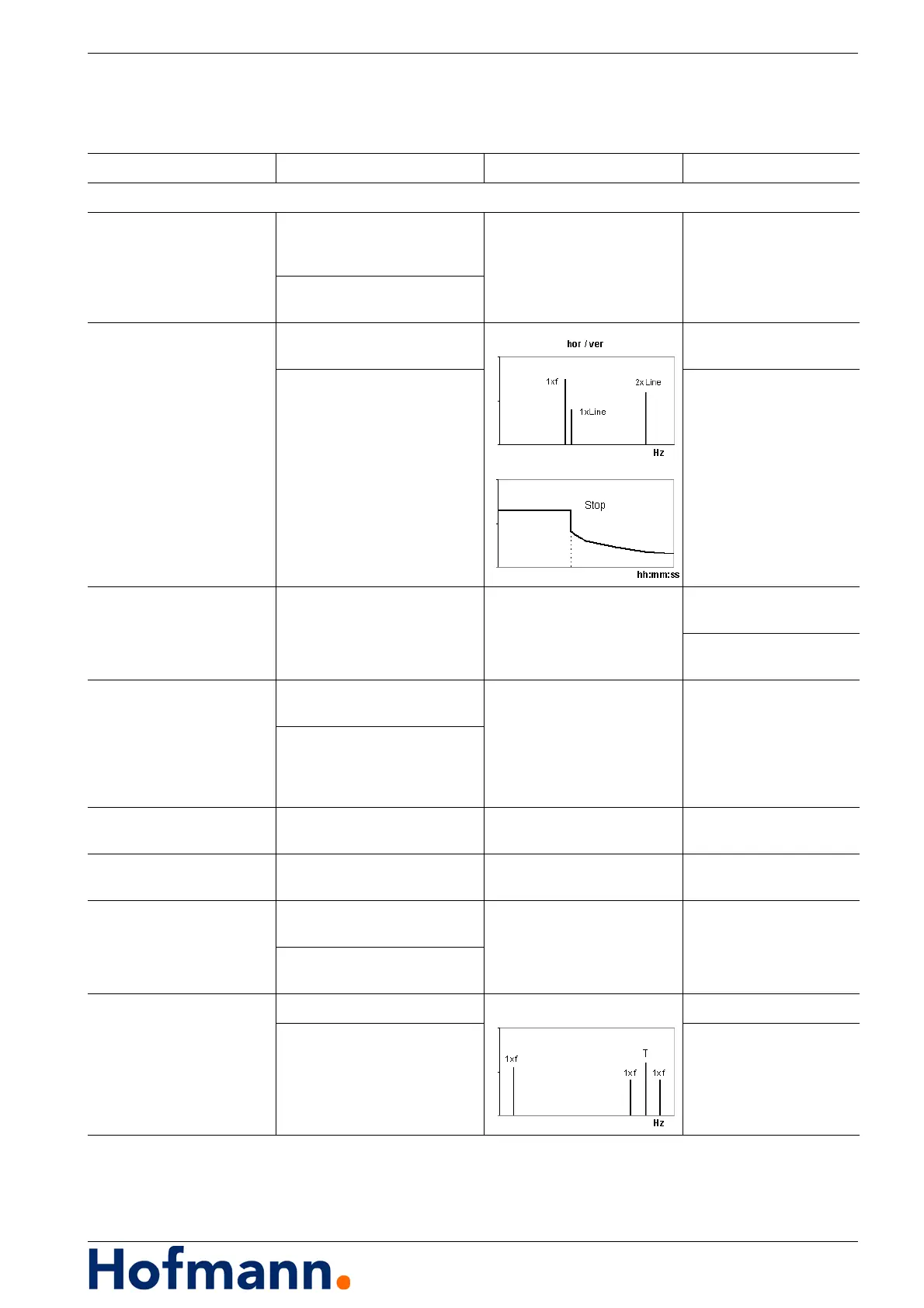

Vibrations with the machine speed 1x f

Unbalance High radial and low axial vibra-

tions with rotors located be-

tween bearings.

Balancing

High radial and high axial vibra-

tion with overhanging rotors.

Magnetic pull on electrical

machines

- Out-of-round rotor

- Eccentric bearing journal

- Bent rotor

- Broken winding

High radial and low

axial vibration

Measure concentricity

and clearance.

Possibly also single

and double line frequency

Vibration disappears

when switching off.

Magnetic pull on electrical

machines

- Axial offset

High radial and high

axial vibration

Check axial position

of rotor to stator.

Vibration disappears

when switching off.

Flat and centring errors

in couplings

High radial and high

axial vibration

Check alignment.

Often proportion with 2x f,

more rarely

3x f for couplings with flexible

intermediate elements

Bent shaft See flat and centring errors

in couplings

Check concentricity.

Bearing offset See flat and centring errors

in couplings

Check alignment of bear-

ing seats.

Eccentricity of pulley High radial and low

axial vibration

Check concentricity

Maximum amplitude in direction

of shaft centres

Eccentricity of gear wheel See eccentricity of pulley Check concentricity.

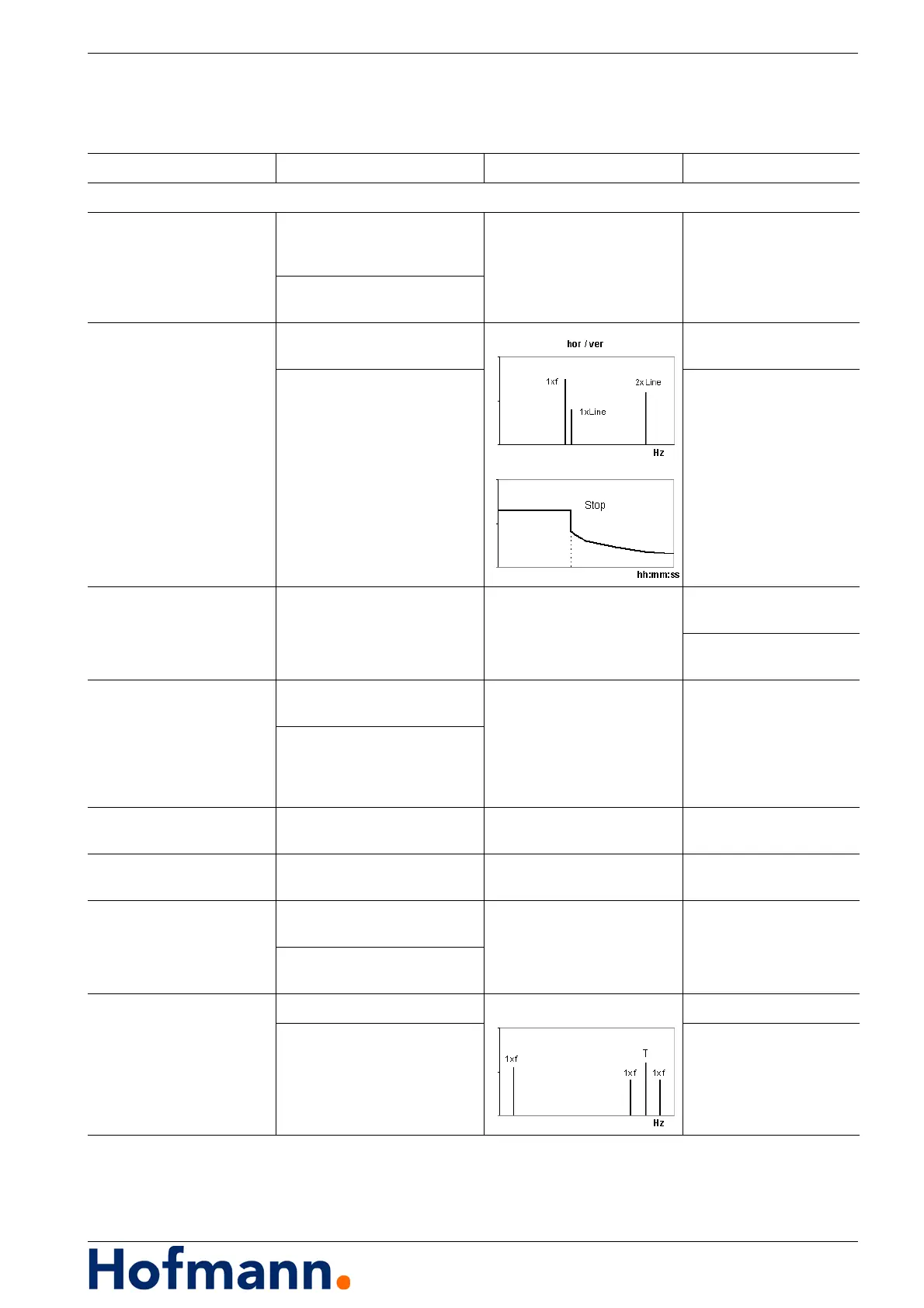

Tooth meshing frequency T with

1x f side straps

Tooth mesh frequency =

Rotational frequency x

Number of teeth.

Loading...

Loading...