Evaluation - Interpretation of vibration measurements EasyBalancer EB 3500

10 - 10

Possible cause Comment Appearance Confirmation of cause

Tooth defects High radial and low

axial vibration

Check gear stages.

Often also 2x f and 3x f compo-

nents

Vibrations with double mains frequency

Out-of-round stator bore or

rotor misalignment

High radial and low

axial vibration

Check concentricity

and clearance.

Vibration disappears

when switching off.

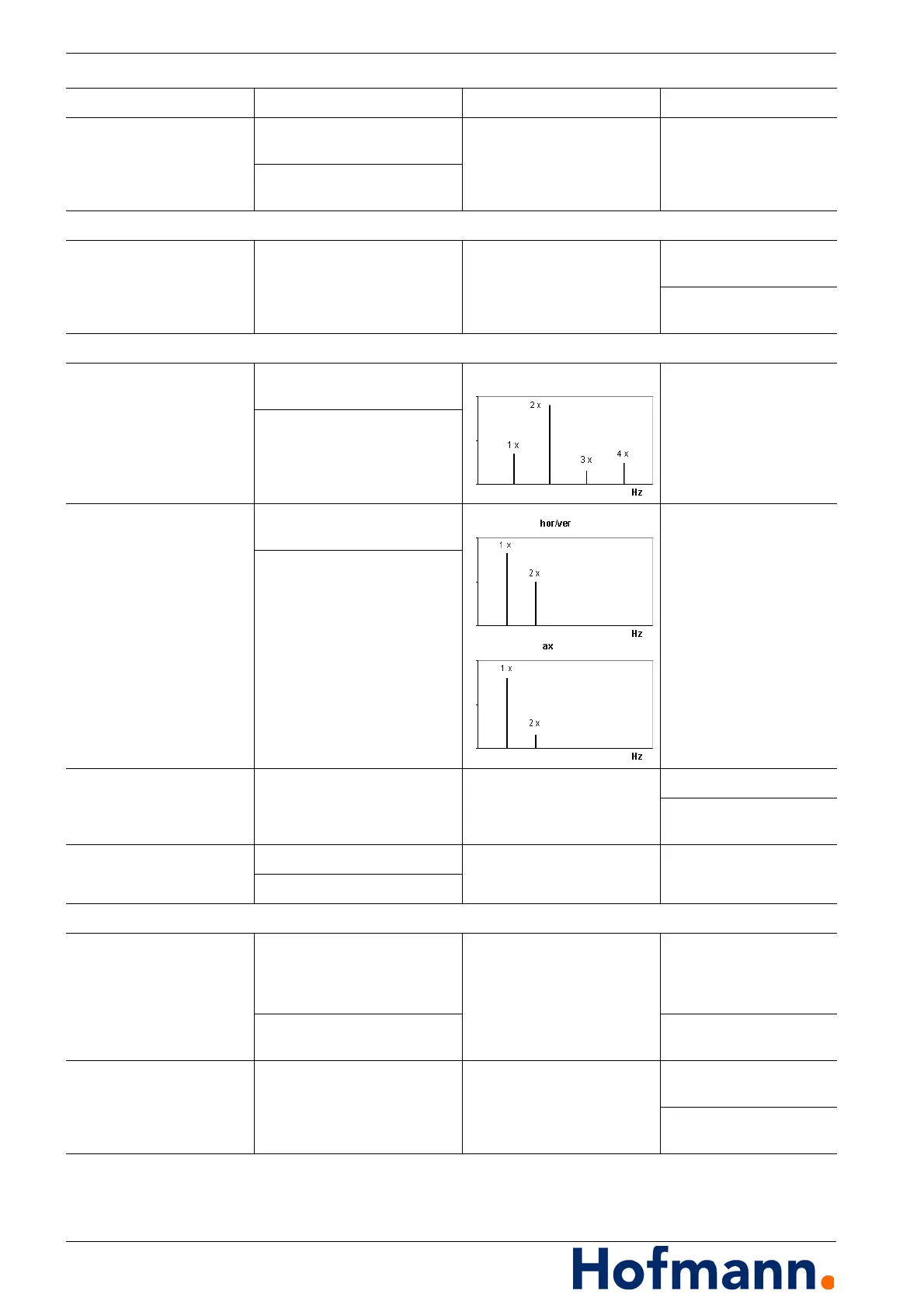

Vibrations with multiple rotational frequency

Loose High radial and low axial

2x f vibration

Check connections.

Often also 1x, 3x

and 4x f components

Flat and centring errors in

couplings

High radial and low

axial 2x f proportion

Check alignment.

Additionally high radial

2x f proportion

Rotor anisotropy, heavily

grooved rotor

2x f proportion

Only with horizontal shafts.

Speed-dependent static

sag

Shaft with crack 2x f proportion Difficulties with balancing.

Also 3x f proportion

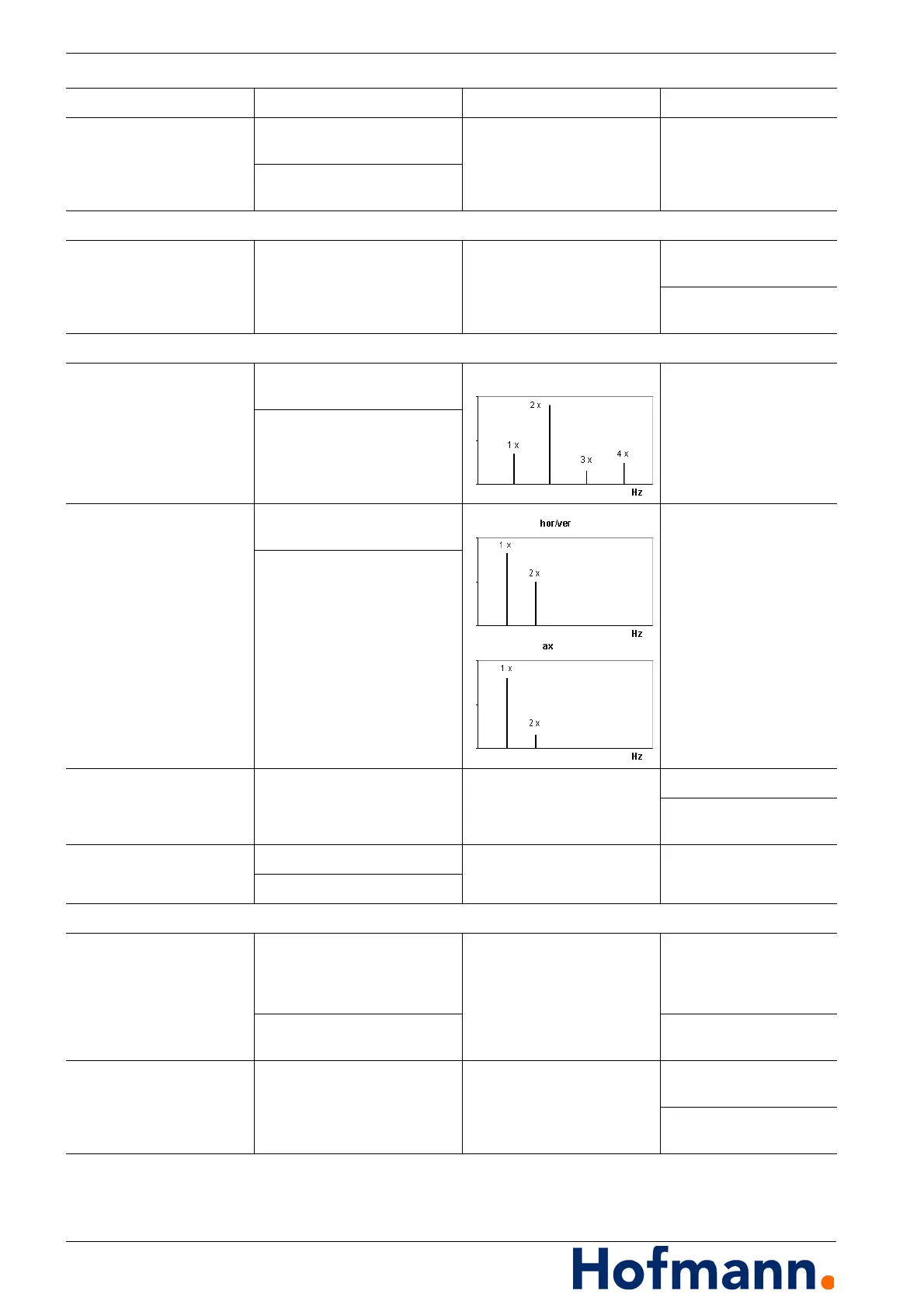

Vibrations at parts of the rotational frequency

Rubbing Slight periodic rubbing can be

seen on vibration components

with 1/4 x, 1/3 x, 1/2 x, 2/3 x

and 1x f

Check clearance, offset

and concentricity.

Also 1/2 x, 1x, 11/2 x and

2x f possible

Slow drift of the phase

position.

Plain bearing instability Vibration with 0.4 x to

0.5 x f

Change oil temperature

and thus oil viscosity.

Further measures by

machine manufacturer

Loading...

Loading...