Roller for ne seeds

The rollers for ne seeds consist of cell discs,

spacers and drive shaft.

In order to avoid malfunction when sowing ne

seed, the cell rollers are completely pre-assem-

bled in the factory.

The rollers can be assembled with one or two

cell discs.

The use of two cell discs on the roller doubles

the delivery rate.

Cell discs are available with displacements of

3.5 cm³, 5 cm³, 10 cm³ and 25 cm³.

During sowing only the cell discs in the roller will

rotate, the spacers are stopped from rotating by

stops on the housing

On machines with double Venturi area

and 2 seed boxes you may only use

rotors with 2 cell discs.

Otherwise the seed is unevenly distrib-

uted to the two halves.

Removing or installing a ne seed rotor

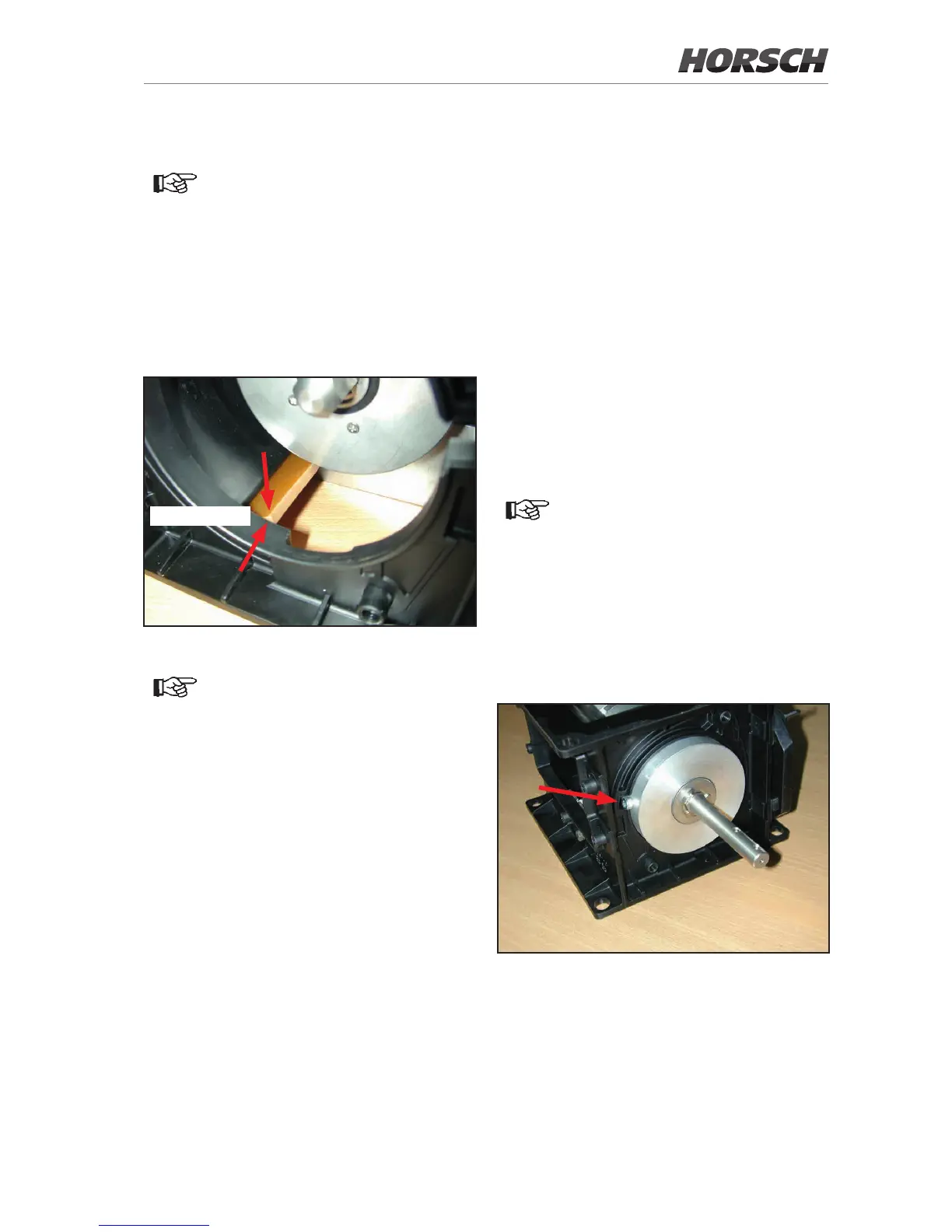

The anti-rotation locks must be turned towards

the recess in the housing in order to remove and

assemble the rollers.

Assembly of roller for ne seeds

Adjusting the sealing lip

A defective sealing lip or an incorrectly

assembled supporting plate causes

metering errors during sowing.

¾ The sealing lip must not be torn or damage

- replace the sealing lip at least 1 × per year.

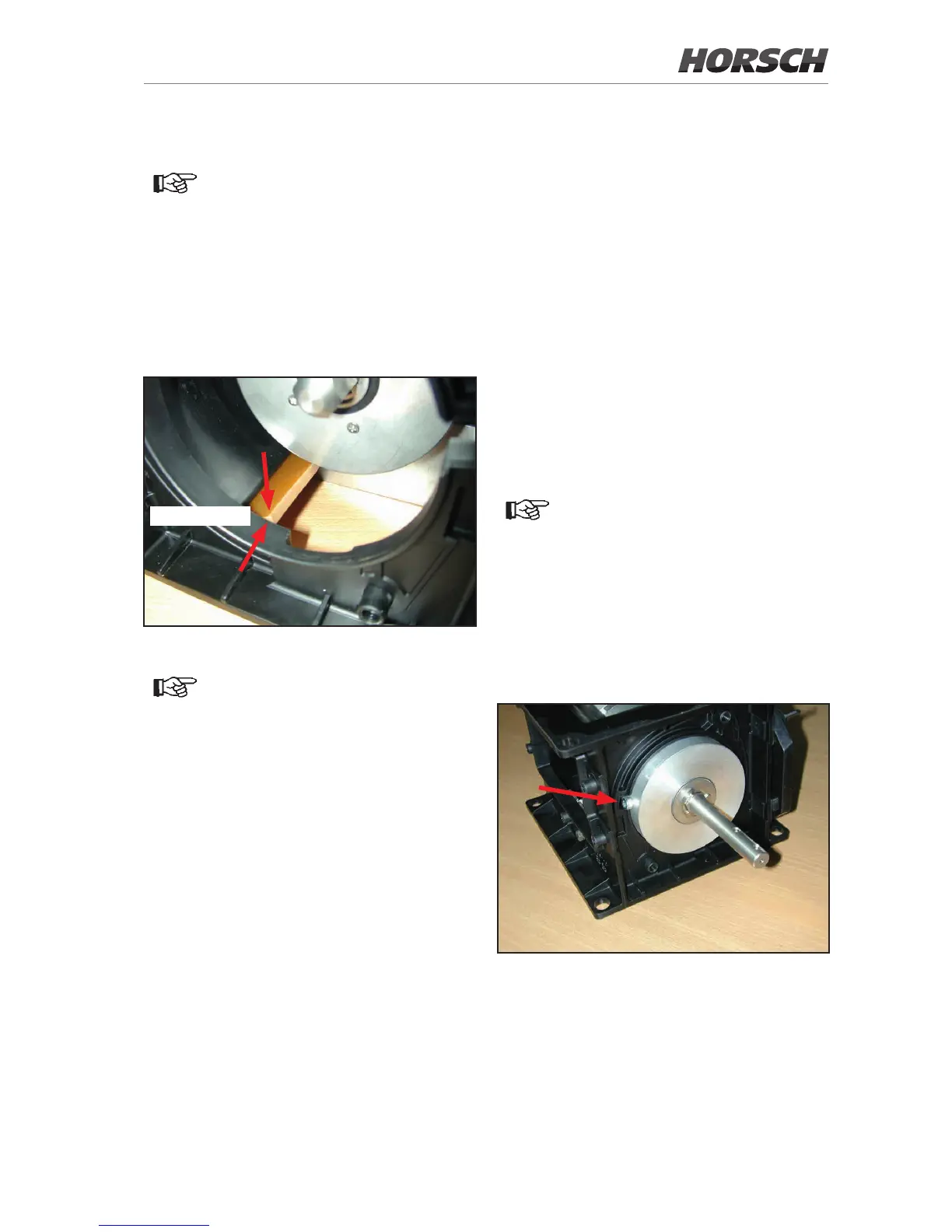

¾ Insert the side cover with the sealing lip into

the metering housing. The sealing lip must

have full contact with the rotor and should be

able to generate approx. 1 mm pre-tension.

approx. 1 mm

Sealing lip

The retaining plate for the sealing lip is

asymmetrically divided.

With all normal and ne seeds the wider side

must face towards the rotor.

In case of disturbances with coarse seeds such

as maize, beans etc. both the retaaining plate and

the sealing lip can be replaced by a wider design.

¾ Take out the rotor.

¾ Insert the side cover with the new sealing lip,

tighten the sealing lip only to such an extent,

that it can still be moved in axial direction.

¾ Move the lip, so that it projects approx. 1 mm

into the roller recess.

¾ Take o the side cover, do not move the lip

any more and tighten it.

¾ Assemble the side cover, check the setting

once again and reassemble rotor.

67

Loading...

Loading...