Chapter 5 Function Introduction Shenzhen Hpmont Technology Co., Ltd.

―42― HD3N-TC Series Inverter User Manual V1.0

Ref. code Name Description Setting Range [Default]

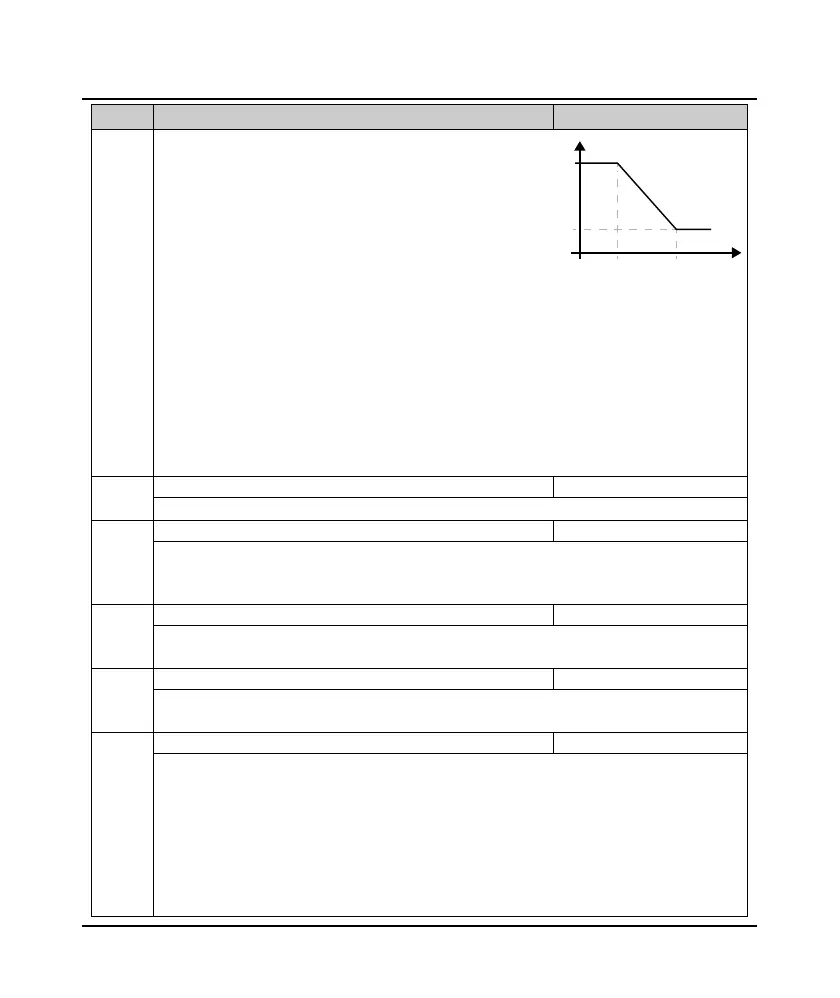

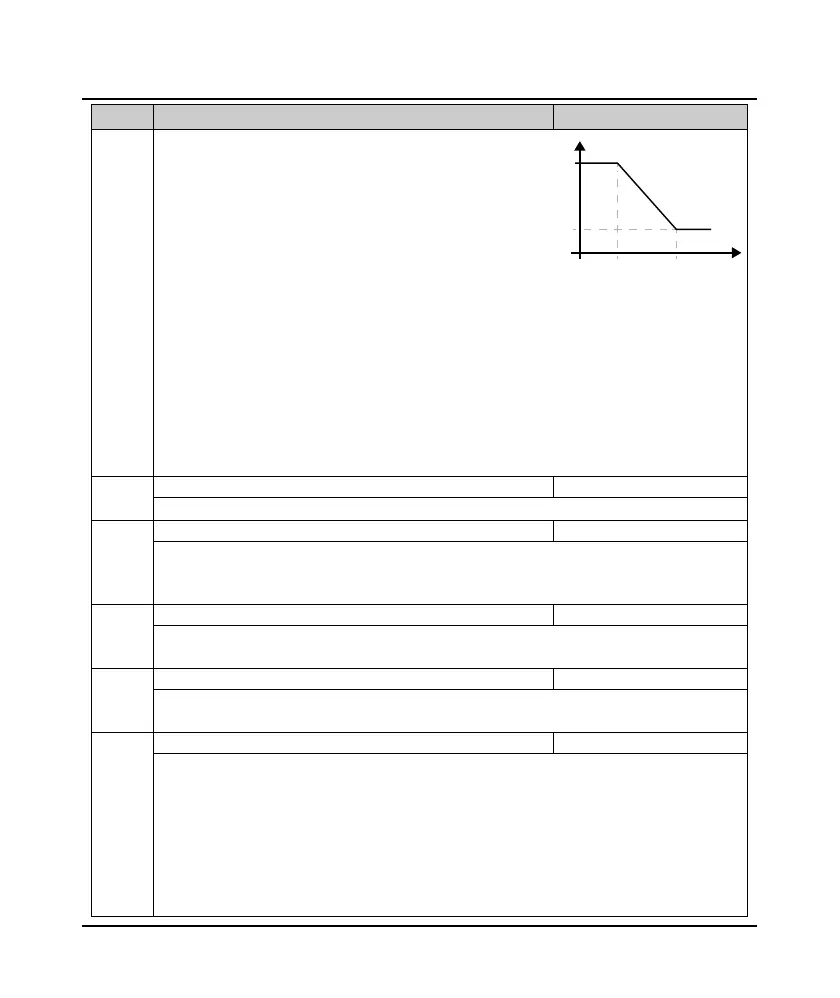

As the right figure:

• When inverter operates within 0 - F10.04, the PI parameters

of vector control are F10.00 and F10.01;

• When inverter operates above F10.05, the PI parameters of

vector control are F10.02 and F10.03;

• When inverter operates within F10.04 - F10.05, P is the linear

interpolation between F10.00 and F10.02, while I is the linear

interpolation between F10.01 and F10.03.

• The system response can be expedited through increasing proportional gain P, but oscillation may occur

if the value of P is too high.

• The system response can be expedited through decreasing ASR integral time Ti, but oscillation and big

overshoot may occur if the value of Ti is too small.

• If integral time constant=0, integral function is not effective, and speed loop is merely a propotional

regulator.

• Generally, adjust proportional gain P first to the max. condition that the system does not vibrate, and

then adjust the Ti to shorten the response time without overshoot.

• To shorten dynamic response time during low frequency running, increase proportional gain and

decrease Ti.

F10.06 ASR integral limit of motor 1 0.0 - 200.0 (F08.02) [180.0%]

It is used to limit the max. value of the vector control speed-loop integral.

F10.07 Motor 1 speed loop differential time 0.00 - 1.00 [0.00s]

Defines the vector control speed-loop differential time.

• Generally do not set F10.07. But to quicken system response, user can properly set it.

• F10.07 = 0, there is no speed-loop differential.

F10.08 Motor 1 speed loop output filter time 0.000 - 1.000 [0.000s]

It is used to filter the output of ASR regulator.

• F10.08 = 0, the speed-loop filter is unused.

F10.09 Locking selection for motor 1 torque limit 0,1 [0]

0: Do not lock.

1: All of the torque limit is same with FWD electric torque limit.

F10.10 Setting channel of motor 1 torque 0000 - 7777 [0000]

Define the setting channel of torque value.

Units: Electric torque limit channel when motor is FWD

Tens: Electric torque limit channel when motor is REV

Hundreds: Braking torque limit channel when motor is FWD

Thousands: Braking torque limit channel when motor is REV

• 0: Limit by digital setting.

• 3 - 4: AI1 - AI2.

• 7: Potentionmeter. Valid when LED keypad adopted only.

F10.04 F10.05

F10.00 /

F10.01

F10.02 /

F10.03

0

Frequenc

PI parameter

Loading...

Loading...