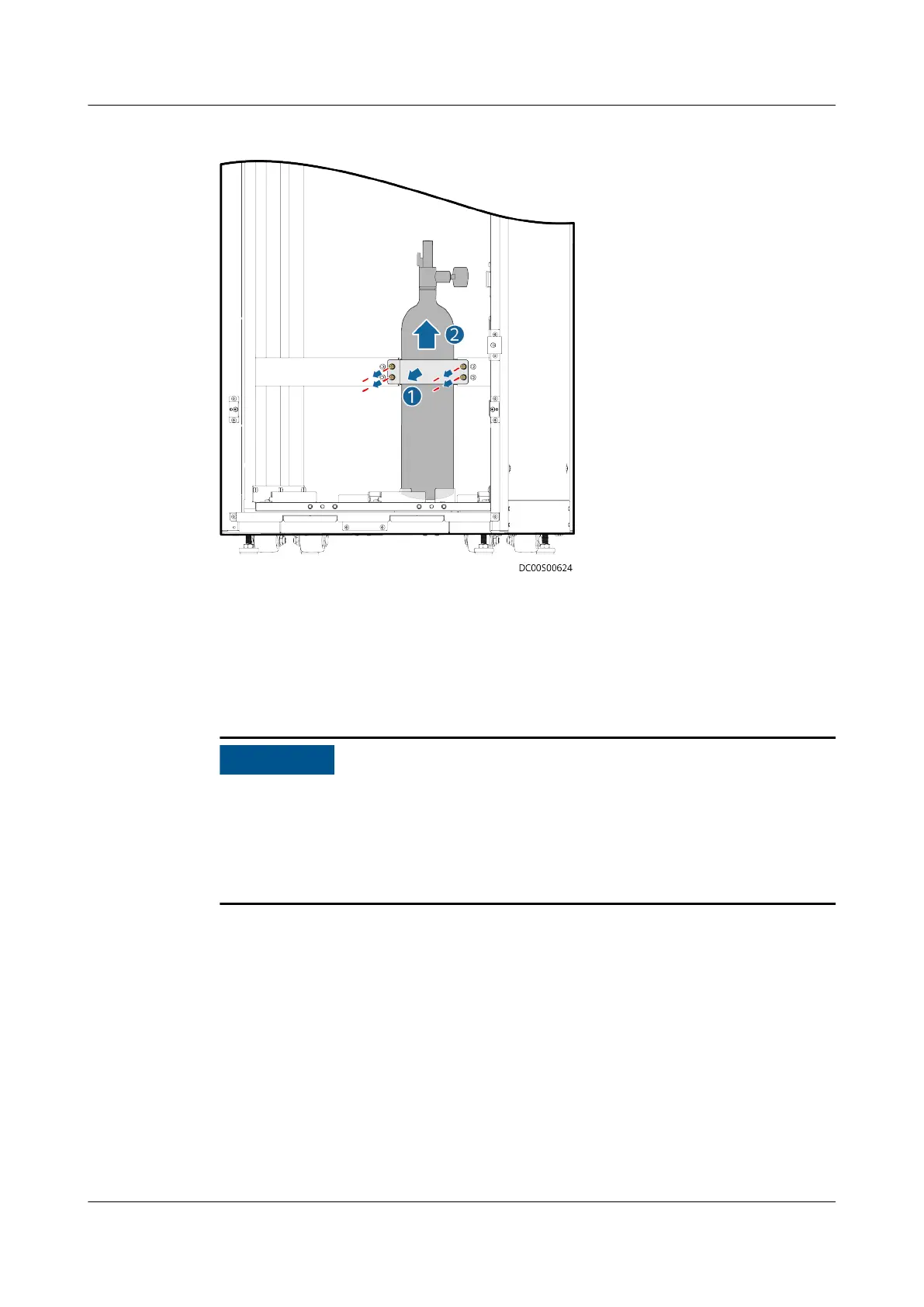

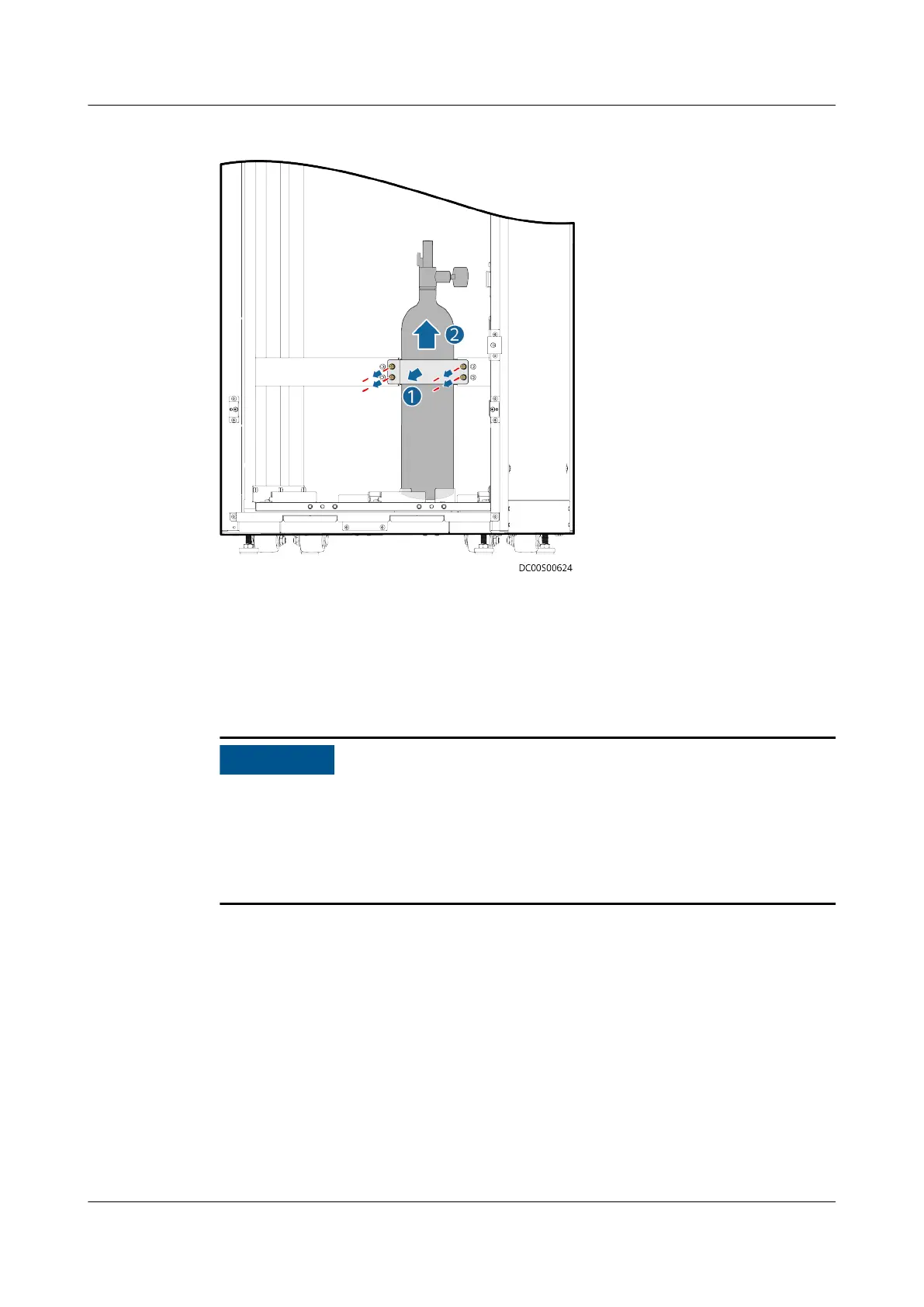

Figure 8-33 Removing the re cylinder

Step 3 Check the re cylinder and all components for any damage, abrasion, or corrosion.

If there is any visible abrasion or corrosion, replace the damaged components and

all corroded components.

Step 4 Send the

re cylinder to the gas station to ll extinguishant. Heptauoropropane

is recommended. The required amount is 3 kg.

● In the process of assembling and lling, ensure that the valve, container, and

other parts are clean and not polluted.

● The internal impurities of the re cylinder have been cleaned and the container

valve has been sealed. Do not remove the container valve and its components.

For other operations, see the related

lling specications.

1. Connect the extinguishant lling port of the container valve to the

extinguishant

lling device. The thread specication of the extinguishant

lling port is M10x1.

2. Remove the valve positioning kit, open the valve, and ll 3 kg extinguishant.

Close the valve after lling the extinguishant.

3. Connect the lling port of the container valve to the nitrogen lling device,

open the valve, and

ll nitrogen until the lling pressure reaches the specied

value. After lling nitrogen, close the valve.

4. Shake the cylinder for 10 times and then ll nitrogen until the pressure

reaches the specied value. Repeat this step for two to three times until the

pressure does not change. Then install the valve positioning kit. After 12

hours, observe the pressure again. If the pressure does not reach the value

FusionDC1000A Prefabricated All-in-One Data

Center

Installation Guide (IT Scenario) 8 Installing Devices Inside the Pre-fab. Module

Issue 01 (2021-04-20) Copyright © Huawei Technologies Co., Ltd. 93

Loading...

Loading...