2.4 Grounding Requirements

● The external ground resistance of the pre-fab. module must not exceed 10

ohms, or the equivalent radius of the ground grid is no less than 5 m.

● The pre-buried ground grid must be at least 0.7 m underground. In cold areas,

the ground electrodes must be buried under the frozen layer.

● A pre-fab. module can be grounded using ground lugs or ground cables.

– Ground lug method: Use a ground lug made of hot-dip zinc-coated

at

steel sheet with a cross-sectional area of 40 mm x 4 mm, connect one

end of the ground lug to the pre-buried ground grid, and connect the

other end to the pre-fab. module ground point. When a ground grid is

pre-buried, the ground lug must be long enough to connect to a ground

point on the pre-fab. module.

– Ground cable method: Use a 95 mm

2

cable as the ground cable, connect

one end of the cable to the pre-buried ground grid, and connect the

other end to the pre-fab. module ground point. When a ground cable is

used, the ground cable must be routed through a plastic-coated metal

hose.

● The screw reserved at a ground point is an M12 screw.

● A pre-fab. module can be grounded in the TN-S or TN-C-S mode.

2.5 Water Rell and Drainage Requirements

2.5.1 Water Rell Requirements

The water rell ports for humidiers must supply water continuously when the

FusionDC1000 is operating.

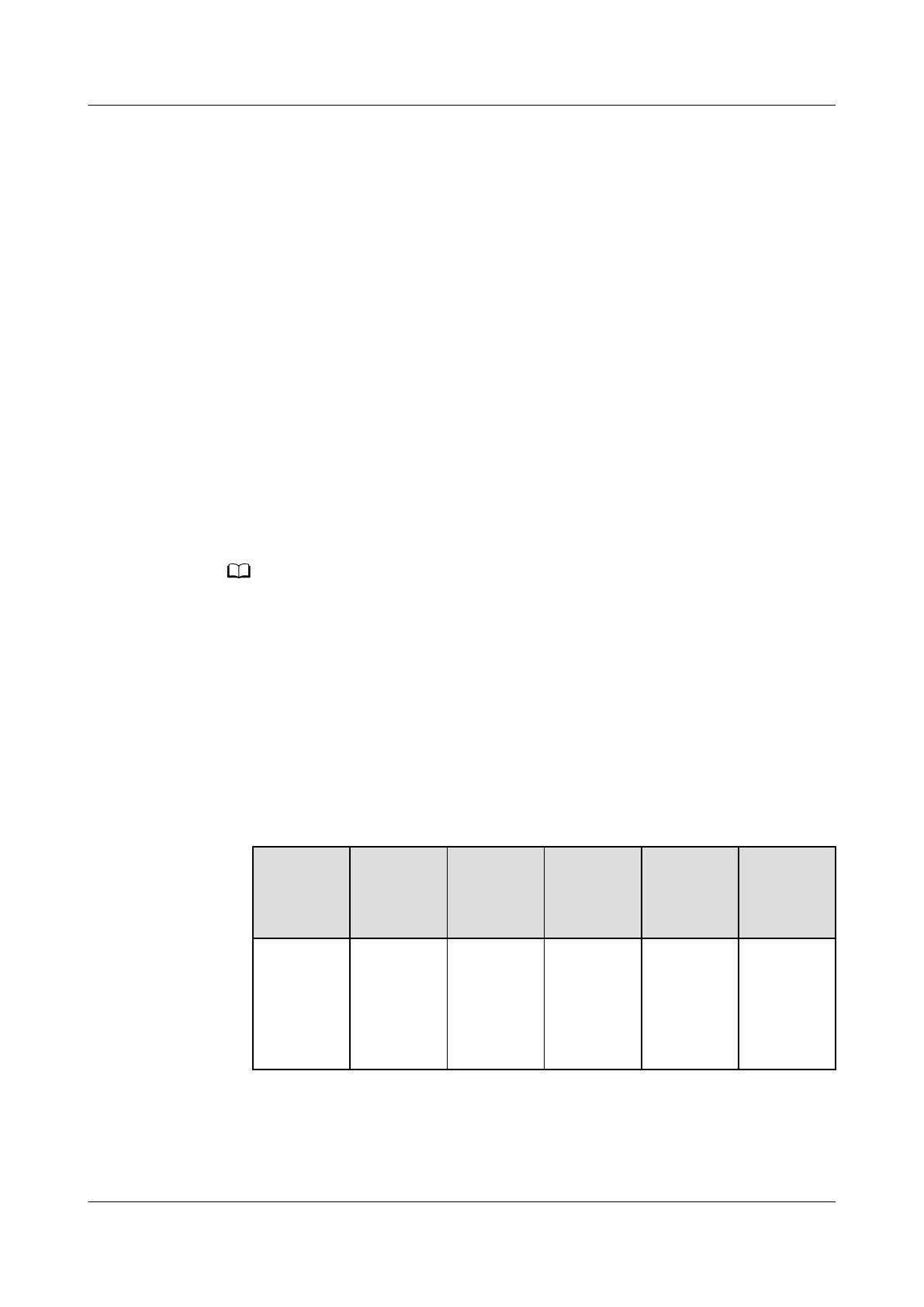

● Table 2-1 Requirements for water

Rell ports and pipes

Port

Position

Port

Dimensio

ns

Water

Pressure

Requirem

ent

Transient

Water

Flow

Pipe

Pressure

Bearing

Capacity

Remarks

For the

humidier

in the

smart

cooling

product

DN25 PP-

R pipe

port

0.1–0.7

MPa

≥ 1.2

L/min

1 MPa Consider

connectivit

y to water

rell

devices.

FusionDC1000A Prefabricated All-in-One Data

Center

Installation Guide (IT Scenario) 2 Site Requirements

Issue 01 (2021-04-20) Copyright © Huawei Technologies Co., Ltd. 19

Loading...

Loading...