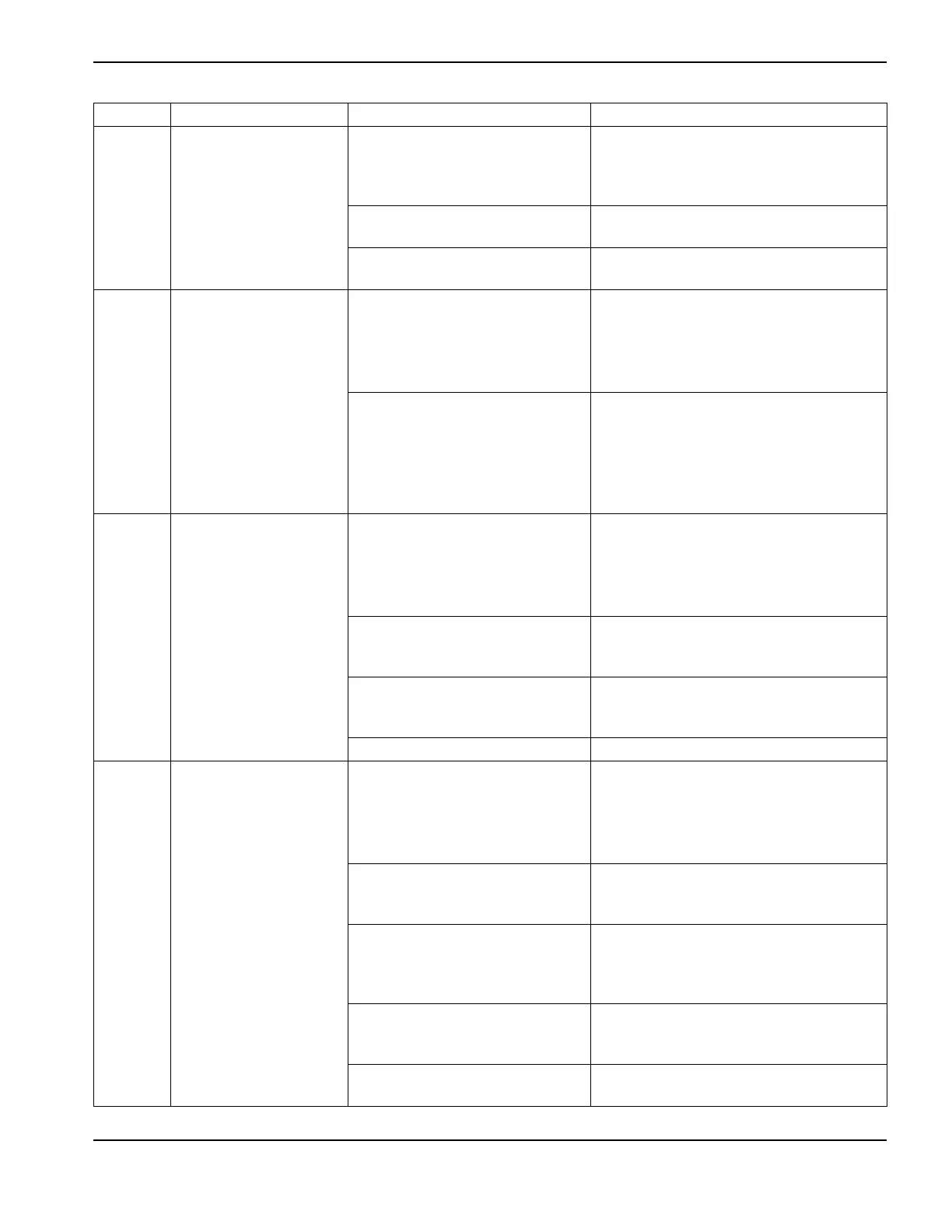

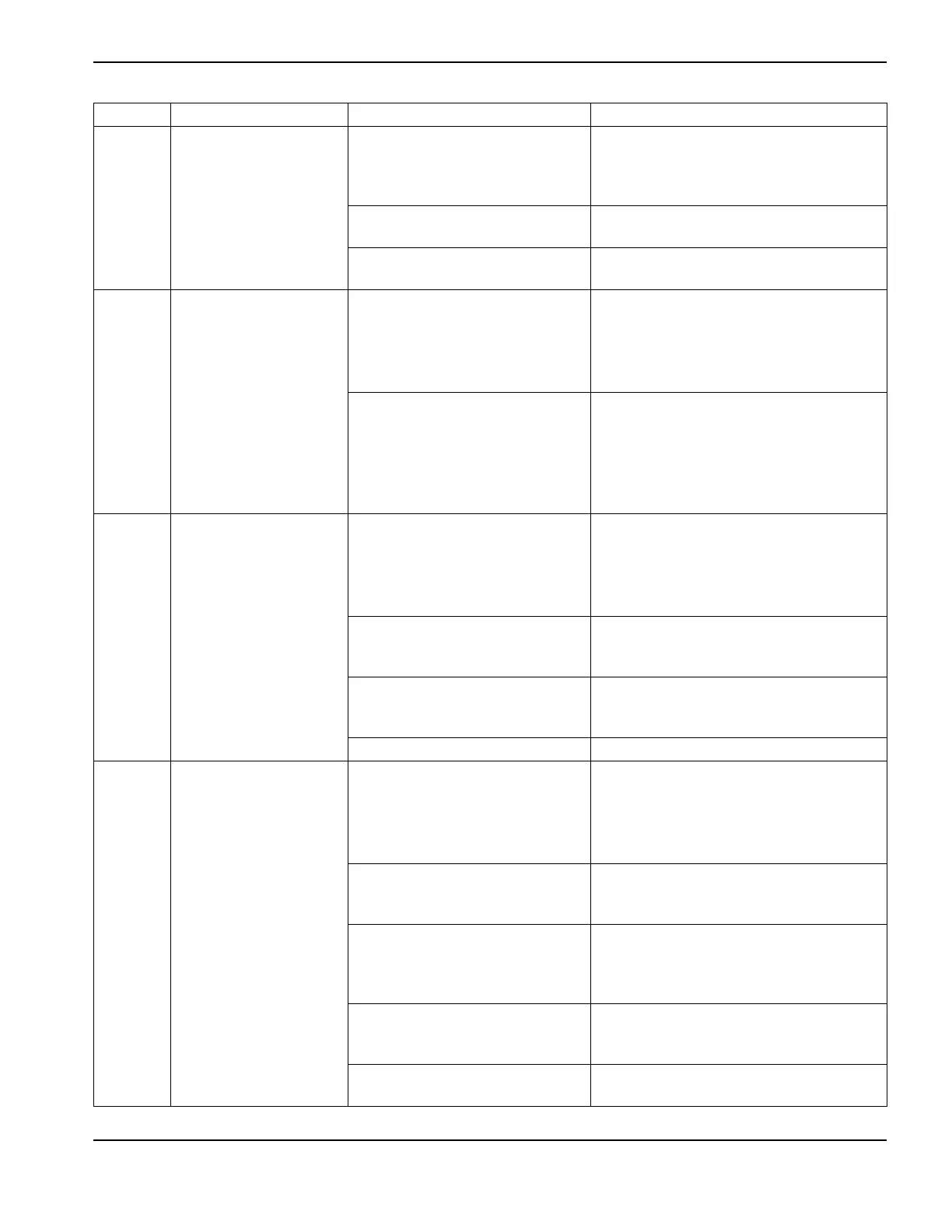

ArcGlide THC Instruction Manual 806450 205

4 – Maintenance

• The control module is mounted

too close to other heat

dissipating devices or

components.

• Verify that other heat dissipating

components are not mounted too close

to the control module.

• The lifter has a mechanical bind. • Examine the lifter and torch leads for

mechanical binding.

• A non-Hypertherm lifter is

drawing to much current.

• Contact the lifter manufacturer.

27 INTERLOCK TRIPPED

The interlock input is

activated.

• An E-stop is depressed on the

cutting machine. There is a

damaged or open wire in the

cutting machine’s E-stop circuit.

• Verify that all E-stops on the cutting

machine are disengaged.

• Examine the E-stop circuit for damage

or a loose connection. Contact your

table manufacturer.

• The interlock input was not

wired as part of the CNC

interface to the control module.

• There is a loose connection to

the interlock input.

• Wire the interlock input to the E-stop

circuit for the cutting machine.

• If this is a new installation, verify that the

interlock input is being used and is part

of the CNC I/O interface to the control

module.

28 BREAKAWAY TRIPPED

The magnetic torch

breakaway has

separated.

• The torch made excessive

workpiece contact or made

contact with the cutting

machine.

• Re-install the magnetic torch

breakaway.

• Verify that the torch is not diving into the

workpiece or hitting an obstruction while

cutting.

• There is debris between the

2 halves of the magnetic torch

breakaway.

• Clean the surface of magnetic

breakaway.

• There is a faulty proximity switch

in the torch breakaway.

• Verify that the proximity switch LED

illuminates when placing a metallic

object over the switch.

• The lifter I/O cable is damaged. • Examine the lifter I/O cable for damage.

29 FIELD SUPPLY FAILED

The +5 V, +/-12 V, or

+24 V supplies are not

within their normal

operating range.

• 120 VAC is applied to the

control module and control

module is configured for

220 VAC.

• Verify that the control module is

configured for the correct line voltage.

• A damaged cable is loading

down one of the control

module’s internal voltages.

• Examine all cables that are plugged into

the control module and plasma interface

board for damage.

• The electrical load that is being

applied to the 24 VDC source

of the control module is too

high.

• Look for excess external loading on the

+24 V supply.

• A faulty component external to

the control module is loading

down one of the voltages.

• Verify that all external components

(relays, proximity switches, etc.) operate

correctly.

• The unit is overheating due to

high ambient temperatures.

• If the unit is operating at a high

temperature, allow it to cool.

Error Description Causes Solutions

Loading...

Loading...