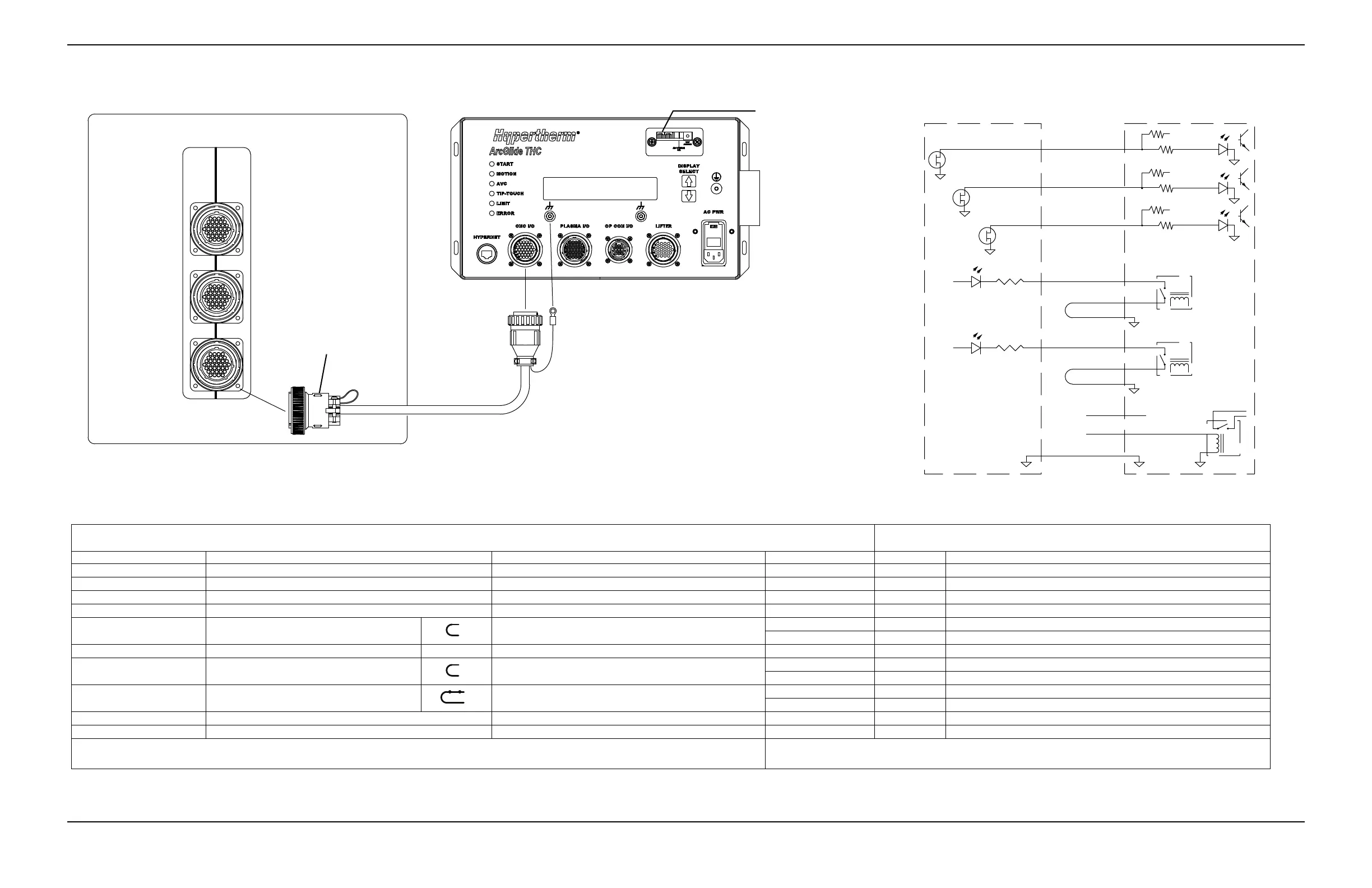

Picopath CNC end A

CNC I/O cable

Picopath interface CNC

I/O

Axes 1, 2

Axes 3, 4

ArcGlide control module

ArcGlide control module end B

Set dry contacts by sliding

the switch to D.

Picopath connector kit (228490)

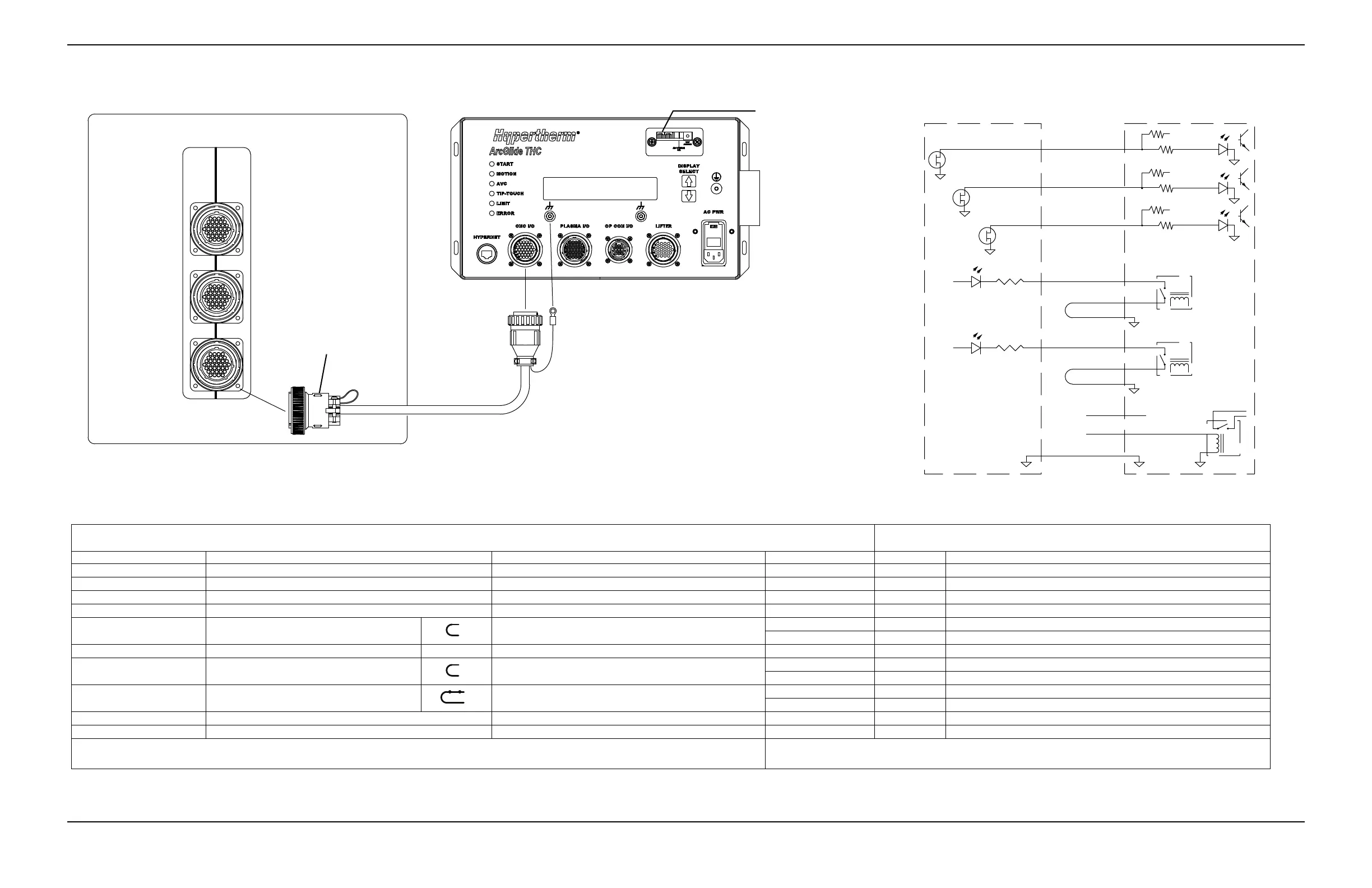

End A of the Hypertherm ArcGlide CNC I/O cable is terminated during installation and will work only if the I/O setup in Phoenix software corresponds to the setup

described in this half of this table.

End B of the Hypertherm ArcGlide CNC I/O cable is terminated at the

factory as described in this half of the table.

Pin No. Function* Phoenix mapping name Wire color* Pin No. Signal

32 Output 12 Cut Control Red 1 Cycle start input +

31 Output 11 Hold Ignition Blue 7 IHS sync input +

30 Output 10 Torch Height Disable Green 5 AVC disable input +

12 Input 12** Cut/Mark Sense Green 17 Machine motion output A

Jumper blue and red, pins 18 and 29.

Red 18 Machine motion output B

Blue 29 Common

11 Input 11** Torch Collision Yellow 21 Torch breakaway output A

Jumper red and green, pins 22 and 30.

Red 22 Torch breakaway output B

Green 30 Common

External switch

Satisfy with switch or jumper.

Orange 25 Interlock input + **

Red 26 Interlock input - **

37 24 V common Yellow 31 Common

Backshell Chassis ground Drain wire Ring terminal Chassis ground

* This example uses CNC outputs 10, 11, 12, and inputs 11 and 12. Assign the I/O points in the Phoenix software.

** Set ArcGlide plasma inputs to dry (D) using the plasma input switch on the THC processor board in the control module.

* Multiple wires are the same color. Verify pin-to-pin connections before plugging cables into equipment.

** ArcGlide interlock must be closed to enable ArcGlide motion.

Loading...

Loading...