OperatiOn

4-52 HPR800XD Auto Gas – 806500

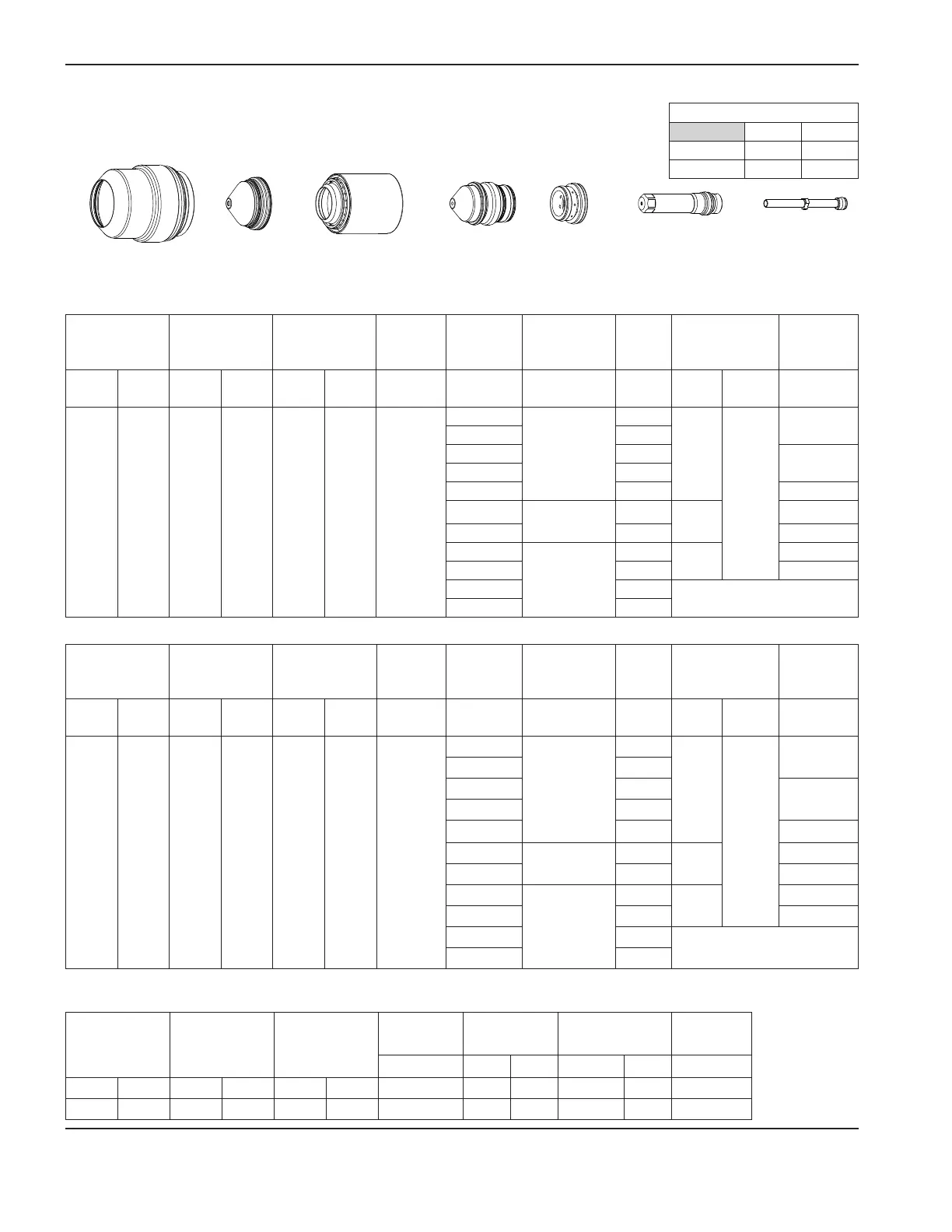

Metric

English

Select

Gases

Set

Preflow

Set

Cutflow

Minimum

Clearance

Equivalent

Material

Thickness

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce

Height

Pierce Delay

Time

Plasma

gas

Shield

gas

Plasma

gas

Shield

gas

Plasma

gas

Shield

gas

mm mm Range (mm) mm/m mm Factor % Seconds

O

2

Air 23 83 69 42 2.0

5

3.3 – 8.4

5700

6.6

200

0.2

6 5250

8 4355

0.3

10 3460

12 3060 0.5

15

4.1 – 8.4

2275

8.2

0.6

20 1575 0.8

25

5.1 – 8.4

1165

10.2

1.0

32 750 2.7

38 510

Edge start

50 255

Select

Gases

Set

Preflow

Set

Cutflow

Minimum

Clearance

Equivalent

Material

Thickness

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce

Height

Pierce Delay

Time

Plasma

gas

Shield

gas

Plasma

gas

Shield

gas

Plasma

gas

Shield

gas

in in Range (in) ipm in Factor % Seconds

O

2

Air 23 83 69 42 0.08

3/16

0.13 – 0.33

230

0.26

200

0.2

1/4 200

5/16 171

0.3

3/8 140

1/2 115 0.5

5/8

0.16 – 0.33

80

0.32

0.6

3/4 65 0.8

1

0.20 – 0.33

45

0.40

1.0

1-1/4 30 2.7

1-1/2 20

Edge start

2 10

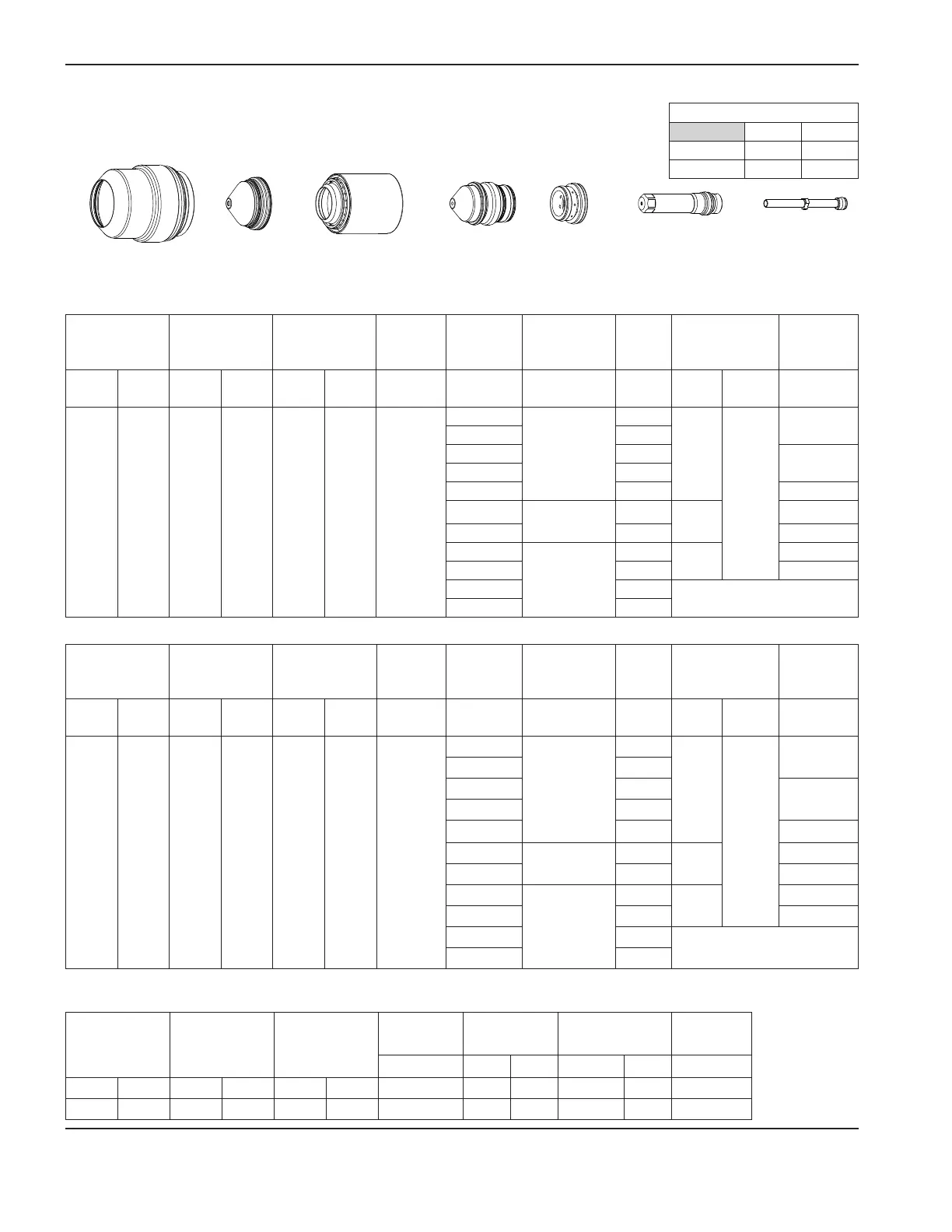

Mild steel bevel cutting

O

2

Plasma / Air Shield

200 A

Flow rates – lpm/scfh

O

2

Air

Preflow 0 / 0 114 / 240

Cutflow 43 / 90 49 / 102

220658

220637

220662220845 220353220659

Note: For mirror-image cutting, use 220996 (nozzle retaining cap) and 220350 (swirl ring) instead.

220700

Select

Gases

Set

Preflow

Set

Cutflow

Amperage

Torch-to-Work

Distance

Marking

Speed

Arc

Voltage

Amps mm in mm/m ipm Volts

N

2

N

2

10 10 10 10 15 2.5 0.10 6350 250 124

Ar Air 30 10 30 10 20 3.0 0.12 2540 100 61

Marking

Loading...

Loading...