Serial Communication Programmer Reference Guide

36 810400 Reference Guide Powermax65/85/105 SYNC

Start and stop a gas test

To start and stop a gas test, the CNC must write a value to the following coil:

0x3180 (coil: gas test)

0x3180 (coil: gas test)

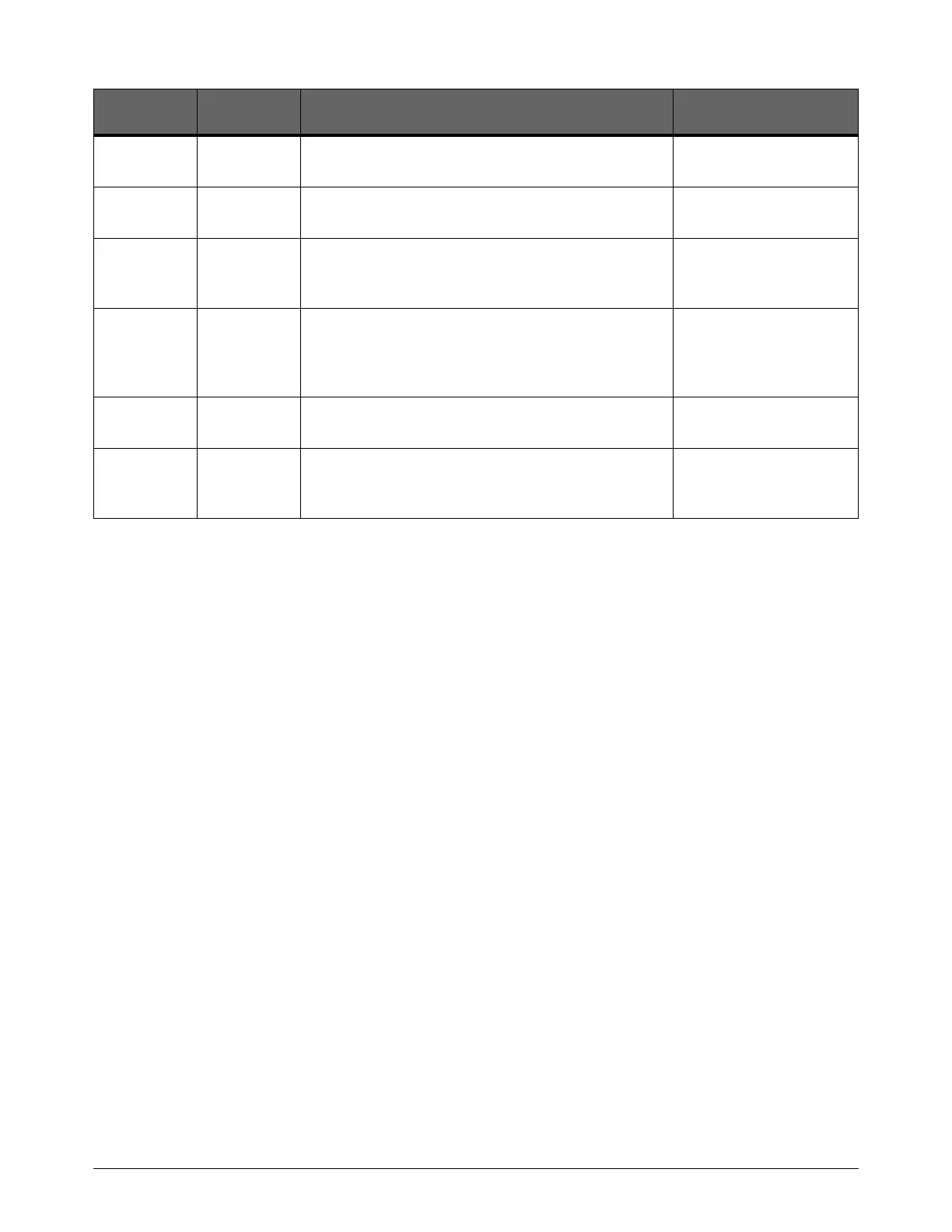

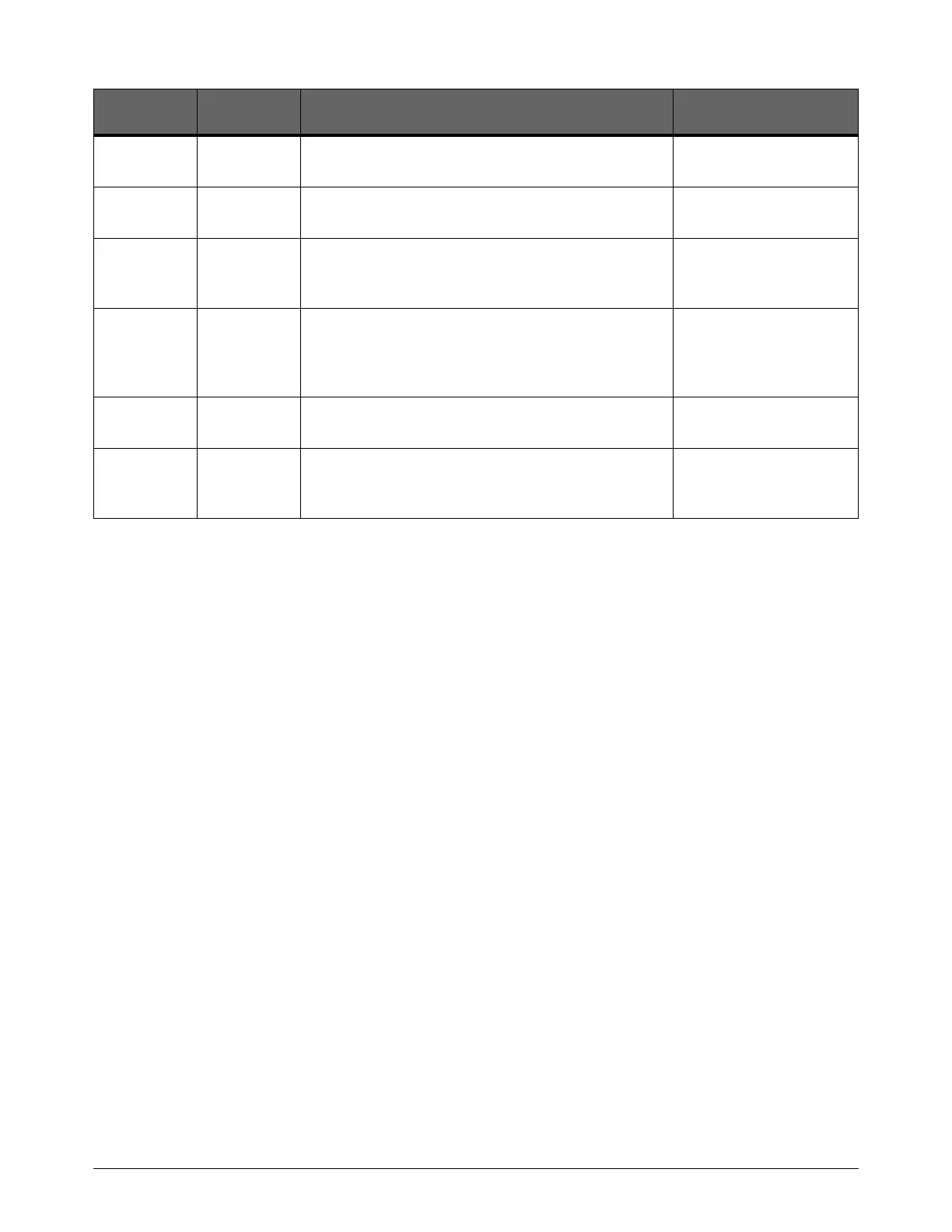

0D66 3430 (Fault code 3-43-0)

The inverter capacitors are not balanced.

Yes

0D71 3441 (Fault code 3-44-1)

The boost PFC IGBT current is too high.

Yes

0DB7 3511 (Fault code 3-51-1)

An inverter IGBT saturation fault occurred. The inverter

current is too high.

Yes

0DC0 3520 (Fault code 3-52-0)

A short-circuit caused high-current distortion in the

inverter IGBT. This is sometimes referred to as a

shoot-through.

Yes

0E10 3600 (Fault code 3-60-0)

The DSP PCB does not recognize the power PCB.

Yes

0E74 3700 (Fault code 3-70-0)

There is an internal serial communications fault

between the DSP PCB and power PCB.

Yes

Fault Code

(hex)

Fault Code

(decimal)

Description

Steps Required to

Remove?

Description: Write a value for ON or OFF to this coil to start or stop a gas test.

• Write 0xFF00 (ON) to start a gas test.

• Write 0x0000 (OFF) to stop a gas test.

Encoding or scaling: N/A

Unit: N/A

Function (hex): 05 (Write Single Coil)

Loading...

Loading...