Serial Communication Programmer Reference Guide

32 810400 Reference Guide Powermax65/85/105 SYNC

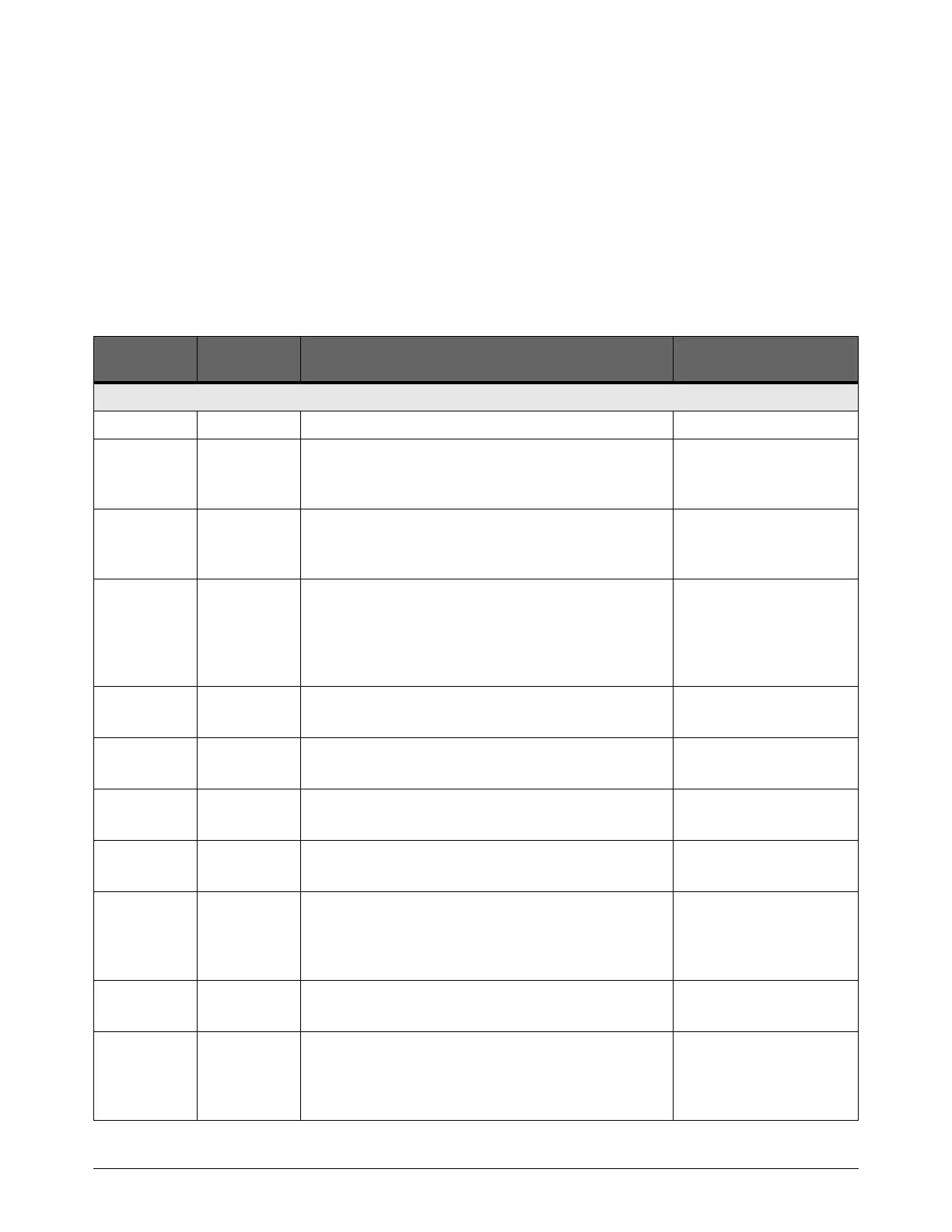

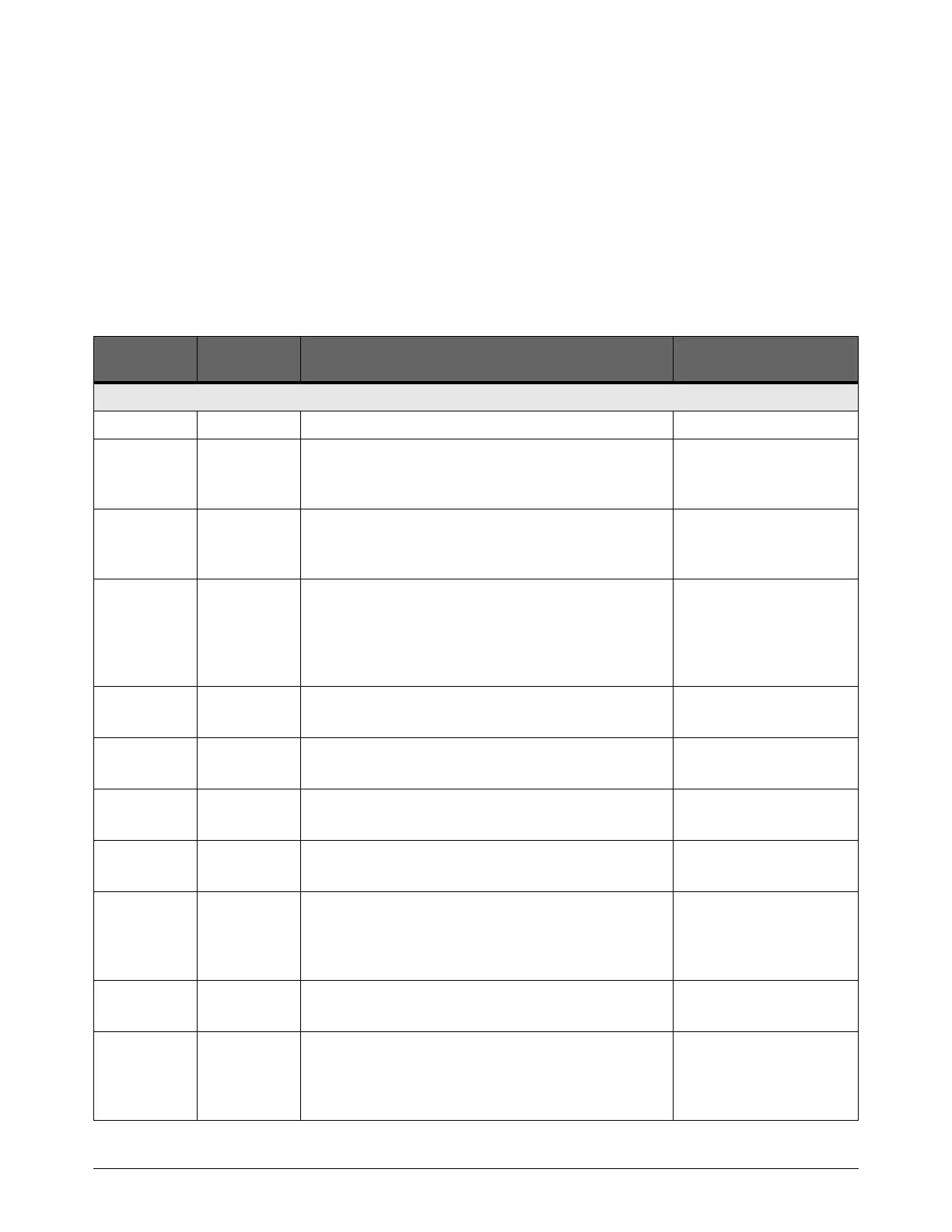

Fault code list

Table 6 lists all of the possible Powermax65/85/105 SYNC fault codes and brief descriptions. For

more information about how to identify and troubleshoot each fault condition, refer to the

Powermax65/85/105 SYNC Troubleshooting Guide (810430).

Hypertherm recommends that you do all the recommended steps for all fault codes that occur,

including notifications that do not stop the cutting process. Troubleshooting all faults helps you to

get optimal cut quality and consumable life.

Table 6 – Fault codes and descriptions

Fault Code

(hex)

Fault Code

(decimal)

Description

Steps Required to

Remove?

Operational faults

0000 0 There is no active fault. No

006E 110 (Fault code 0-11-0)

The operating mode is incorrect or not permitted for the

installed cartridge.

No, but recommended

006F 111 (Fault code 0-11-1)

The output current (A) is incorrect or not permitted for

the installed cartridge.

No, but recommended

0070 112 (Fault code 0-11-2)

The gas pressure is incorrect or not permitted. The

permitted gas pressure relates to the selected process

and operating mode, and to the installed torch, torch

lead, and cartridge.

No, but recommended

0079 121 (Fault code 0-12-1)

The gas pressure output is low.

No, but recommended

007A 122 (Fault code 0-12-2)

The gas pressure output is high.

No, but recommended

007B 123 (Fault code 0-12-3)

The gas pressure output is not stable.

No, but recommended

0082 130 (Fault code 0-13-0)

The alternating current (AC) input power is not stable.

No, but recommended

008C 140 (Fault code 0-14-0)

There is a problem with the cartridge installation. The

cartridge cannot send data to the plasma power

supply.

Yes

008D 141 (Fault code 0-14-1)

The cartridge is not recognized.

No, but recommended

00C7 199 (Fault code 0-19-9)

The input power stopped. Or, power PCB hardware

protection occurred for components in the plasma

power supply.

No, but recommended

Loading...

Loading...