Serial Communication Programmer Reference Guide

Powermax65/85/105 SYNC Reference Guide 810400 33

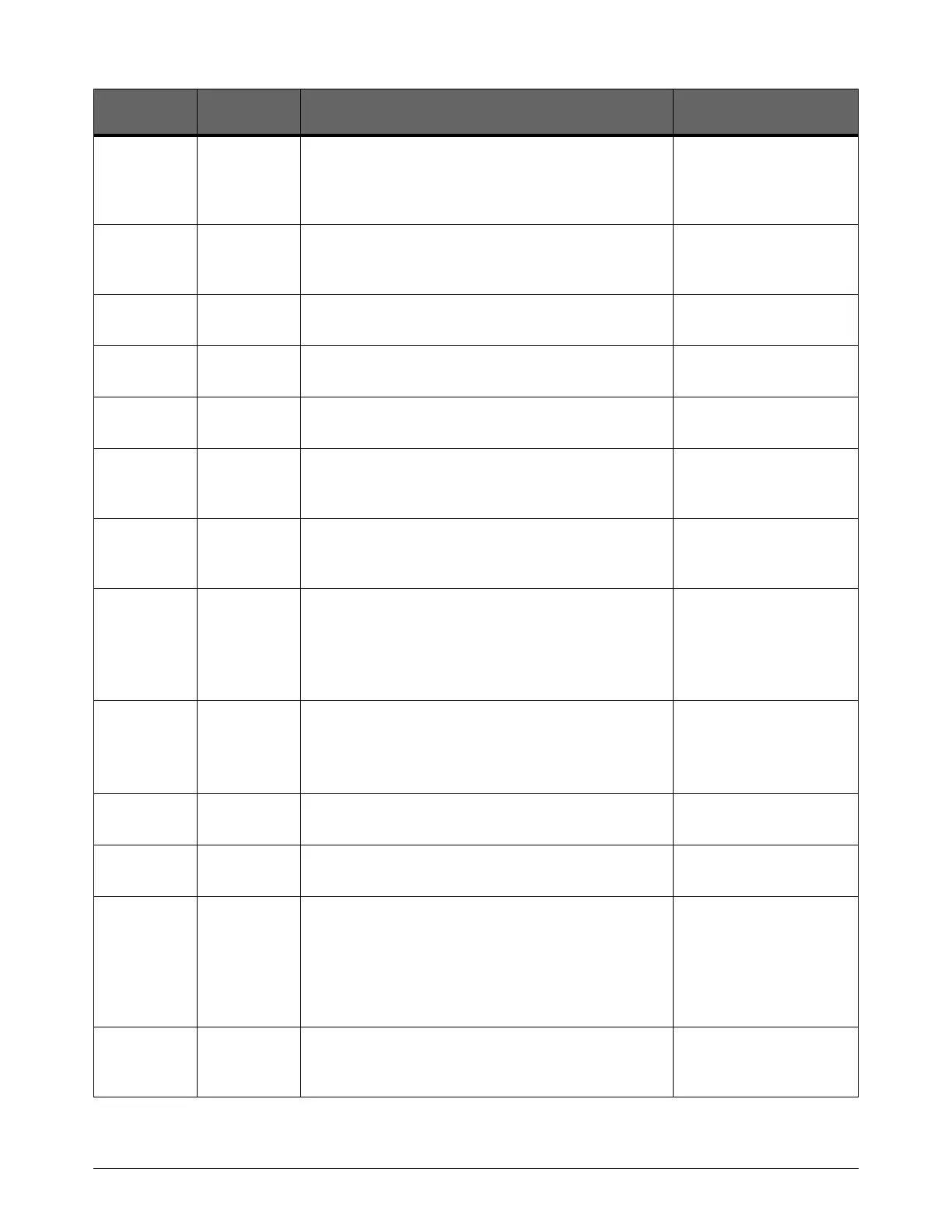

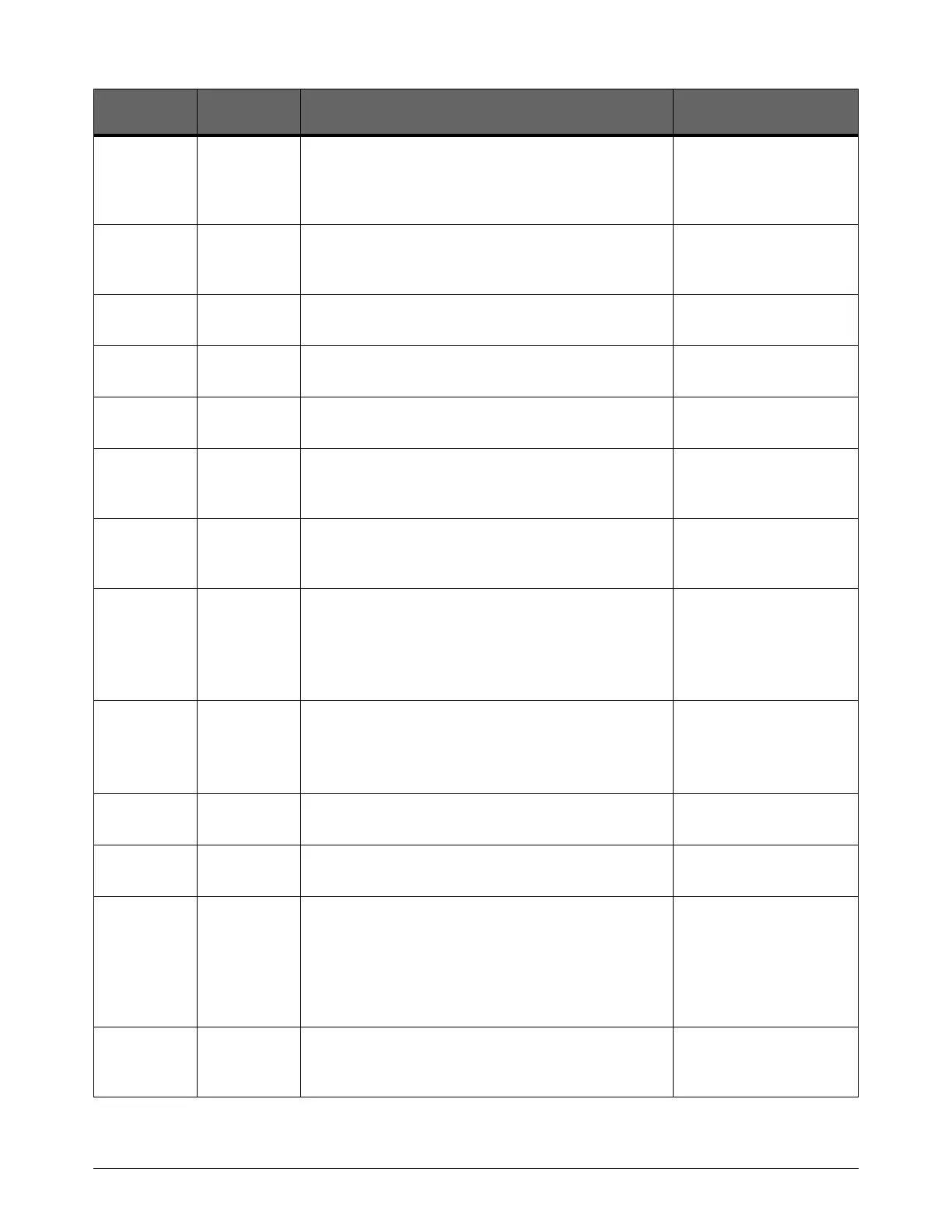

00C8 200 (Fault code 0-20-0)

The gas pressure is lower than the minimum pressure

for the selected process, operating mode, torch, lead

length, and cartridge type.

Yes

00D2 210 (Fault code 0-21-0)

The gas flow stopped during cutting (an excessive

change to arc voltage occurred).

Yes

00DC 220 (Fault code 0-22-0)

There is no gas supply input.

Yes

012C 300 (Fault code 0-30-0)

There is a torch stuck open (TSO) condition.

Yes

012D 301 (Fault code 0-30-1)

There is a torch stuck closed (TSC) condition.

Yes

0140 320 (Fault code 0-32-0)

The system sensed that the cartridge in use is at

end-of-life.

Yes

0141 321 (Fault code 0-32-1)

A used cartridge was installed that had the 0-32-0 fault

before and is at end-of-life.

No, but recommended

0190 400 (Fault code 0-40-0)

The boost power-factor correction insulated-gate

bipolar-transistor (PFC IGBT) is too cold.

This is applicable to CSA and CE/CCC 230 V –

400 V models only.

Yes

0191 401 (Fault code 0-40-1)

The boost PFC IGBT is too hot.

This is applicable to CSA and CE/CCC 230 V –

400 V models only.

Yes

0192 402 (Fault code 0-40-2)

The inverter IGBT is too cold.

Yes

0193 403 (Fault code 0-40-3)

The inverter IGBT is too hot.

Yes

01F4 500 (Fault code 0-50-0)

The cartridge is off.

Or, you removed the cartridge without first setting the

power switch on the plasma power supply to OFF (O)

or moving the torch-lock switch to the yellow lock (X)

position.

Yes

01F5 501 (Fault code 0-50-1)

The torch-lock switch is set to the yellow lock (X)

position.

Yes

Fault Code

(hex)

Fault Code

(decimal)

Description

Steps Required to

Remove?

Loading...

Loading...