Powermax65/85/105 SYNC Reference Guide 810400 61

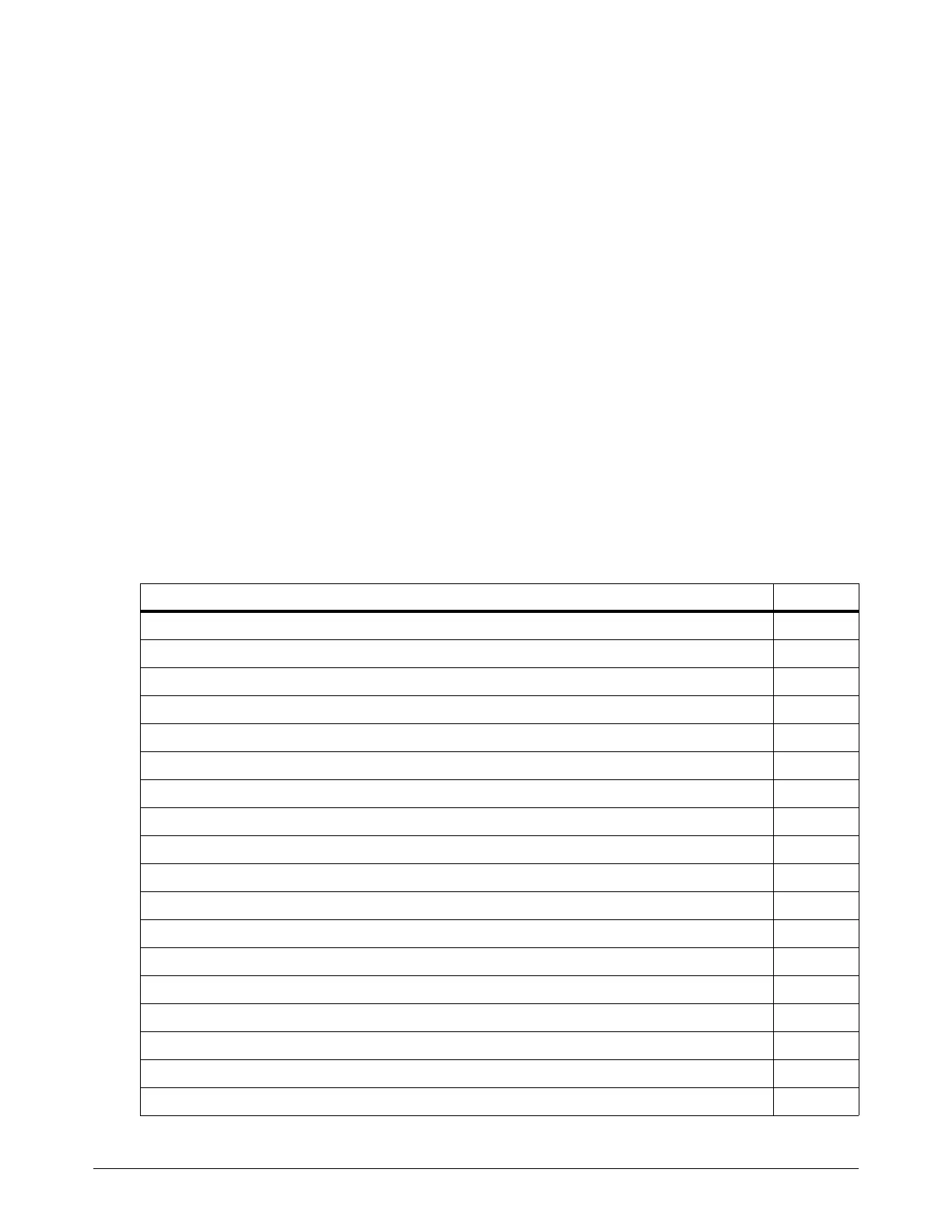

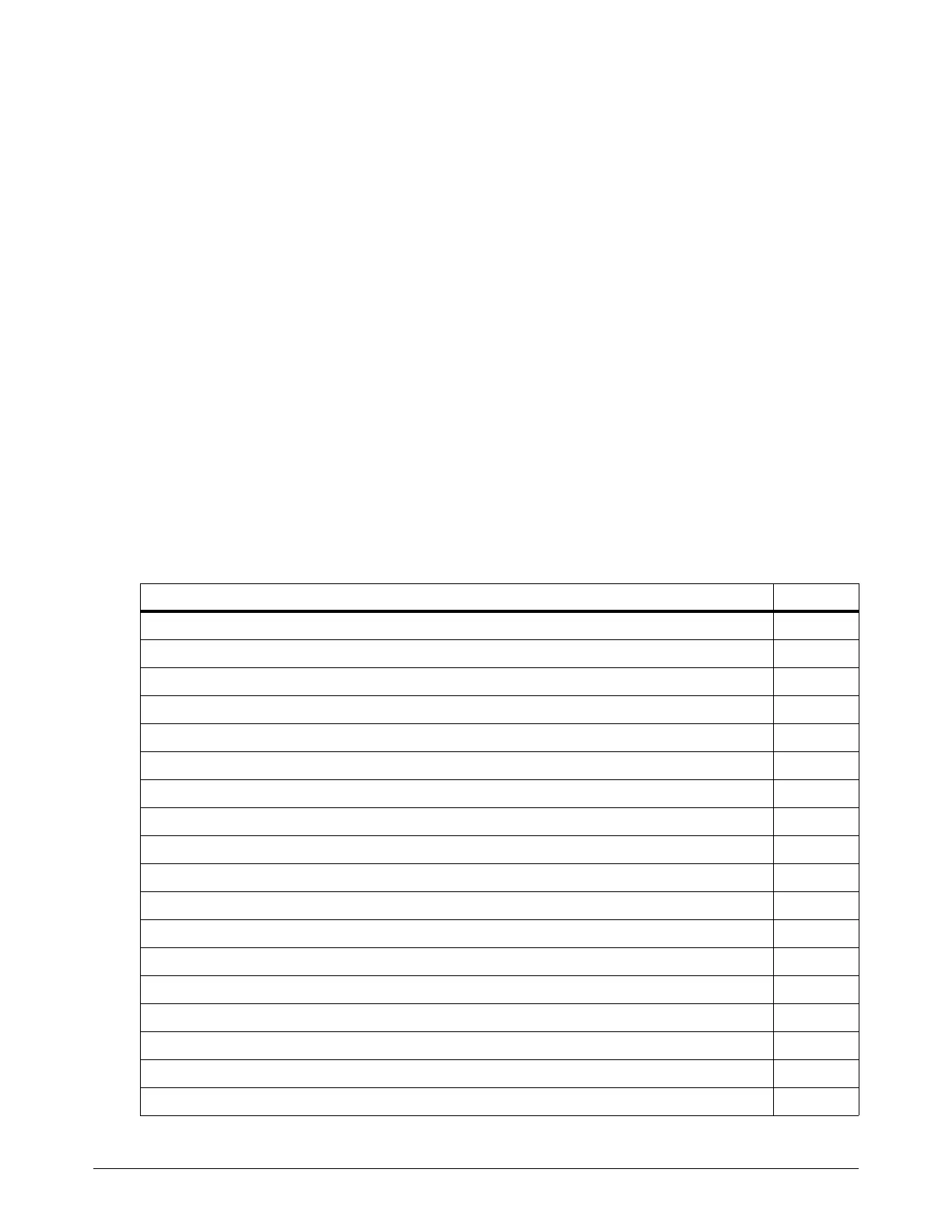

Flowchart Examples

This section contains examples of how you can program your CNC using the information in this

guide. Examples for Powermax65/85/105 SYNC and older plasma power supplies are included.

Older Powermax plasma power supplies include Powermax65/85/105/125 and Powermax45 XP.

Example Page

Figure 1 – Operator selects the plasma power supply type (SYNC / older) page 62

Figure 2 – CNC automatically selects the plasma power supply type (SYNC / older) page 63

Figure 3 – CNC requests plasma power supply and torch lead information page 64

Figure 4 – Exit remote control mode page 64

Figure 5 – CNC reads and sets permitted cut mode, amperage, and gas pressure page 65

Figure 6 – CNC requests SYNC plasma power supply and cartridge data page 66

Figure 7 – CNC starts and stops a gas test page 67

Figure 8 – Serial communications during SYNC quick restart and cold restart (fault 0-19-9) page 68

Figure 9 – Continue cutting after SYNC restart, cartridge change, or cartridge fault page 69

Figure 10 – Clear SYNC cap-off fault 0-50-0 with a quick restart page 70

Figure 11 – Continuously check for SYNC faults / plasma power supply readiness page 71

Figure 12 – SYNC faults that clear with the next Start signal page 72

Figure 13 – SYNC faults that require action to continue to cut page 73

Figure 14 – Request data from older Powermax plasma power supplies page 74

Figure 15 – Operator or CNC does gas test to check air supply capacity page 75

Figure 16 – Behavior when SYNC tries to read the cartridge after cartridge installation page 76

Figure 17 – (Mech/mini) Cartridge cannot send data to the power supply (fault 0-14-0) page 77

Figure 18 – (Hand torch) Cartridge cannot send data to the power supply (fault 0-14-0) page 78

Loading...

Loading...