Serial Communication Programmer Reference Guide

70 810400 Reference Guide Powermax65/85/105 SYNC

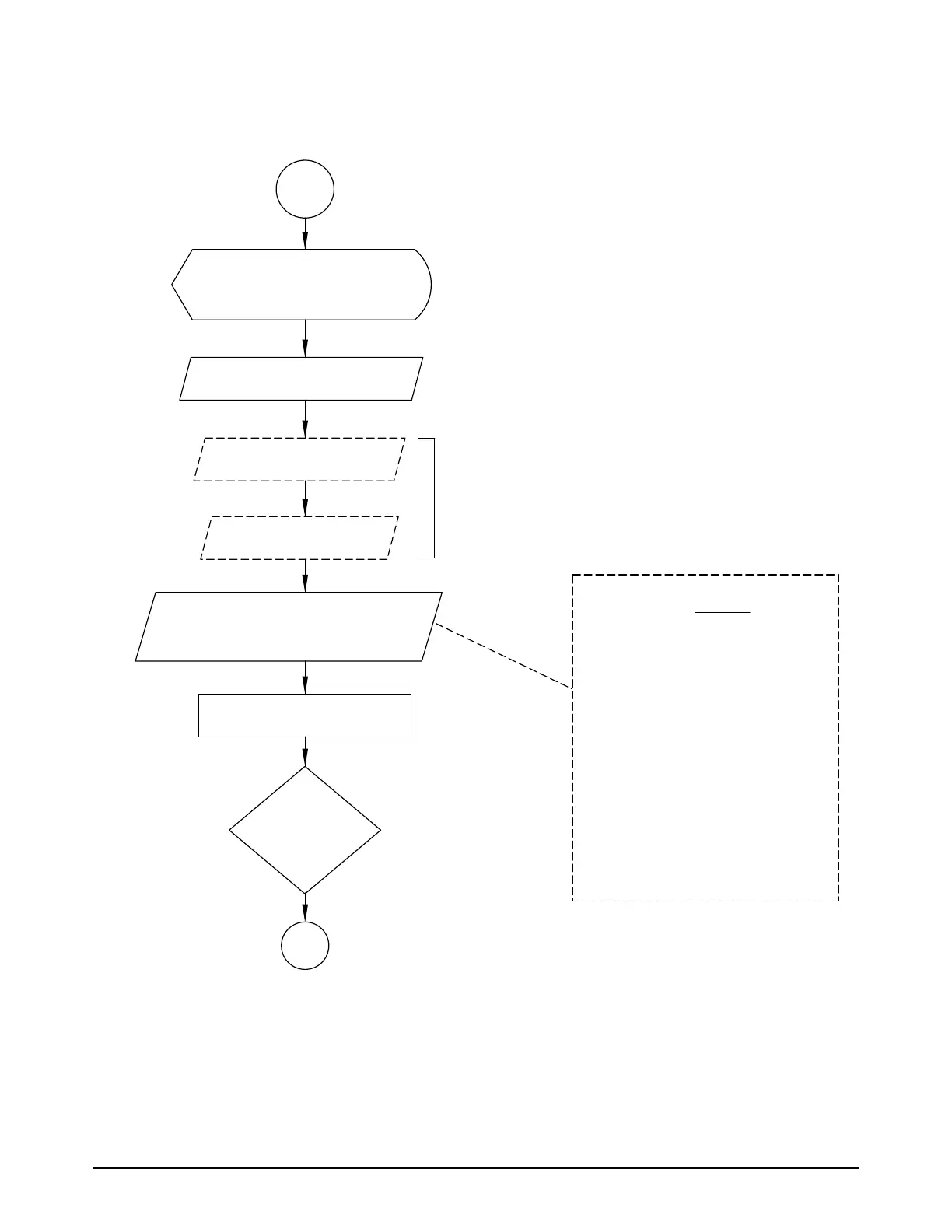

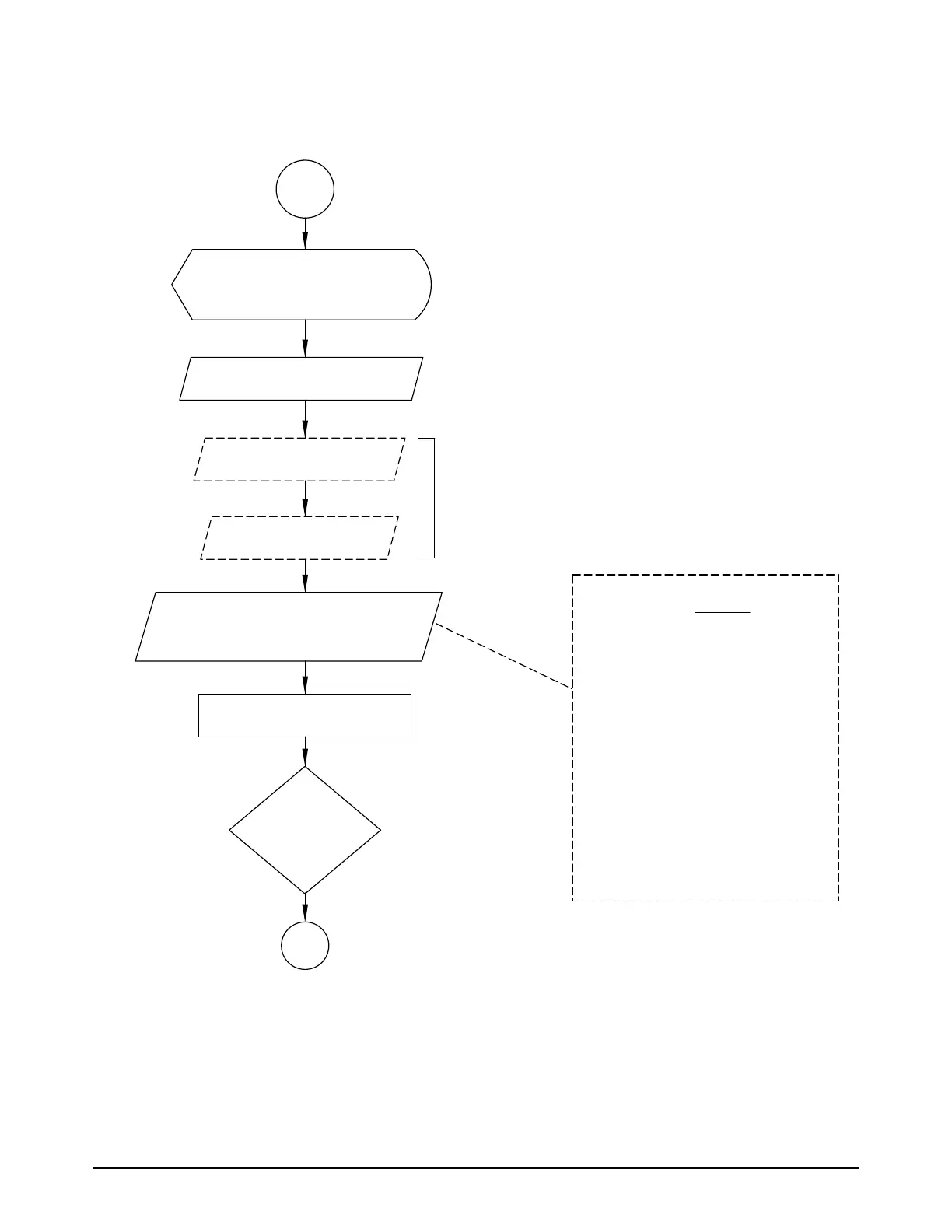

Figure 10 – Clear SYNC cap-off fault 0-50-0 with a quick restart

CNC DISPLAYS A

CONFIRMATION DIALOGUE.

0-50-0

FAULT

QUICK RESTART. REGISTER WRITE

COMMAND CODE 0x0404 TO 0x308E

AND APPROVAL CODE 0x0618 TO 0x308F.

USER PRESSES A SOFT KEY TO

RESTART THE POWERMAX.

EXIT

CNC DISPLAYS 0-50-0 CAP OFF

FAULT MESSAGE. INSTRUCTS

USER TO INSTALL A CARTRIDGE.

USER PRESSES A SOFT

KEY TO CONFIRM.

CHECK FOR

FAULT.

REGISTER READ

0x0301A

WAIT 2 SECONDS FOR

POWER SUPPLY TO RESTART.

OPTIONAL USER

CONFIRMATION

QUICK RESTART REQUEST EXAMPLE

:0110308E000204 04040618

05

01 = POWERMAX ID

10 = WRITE MULTIPLE REGISTERS

308E = STARTING ADDRESS

0002 = QUANTITY OF REGISTERS

04 = BYTE COUNT

0404 = QUICK RESTART COMMAND CODE

0618 = QUICK RESTART APPROVAL CODE

05 = LRC

EXAMPLE RESPONSE

:0110308E00022F

:01 = POWERMAX ID

10 = MULTIPLE REGISTERS

308E = STARTING ADDRESS

0002 = 2 REGISTERS

2F = LRC

NOTES:

1: THE MINI MACHINE TORCH DOES NOT HAVE A LOCK/UNLOCK SWITCH. REMOVING THE CARTRIDGE WITH-

OUT POWERING OFF THE POWER SUPPLY WILL CAUSE A 0-50-0 FAULT, WHICH PREVENTS A PLASMA START.

2. ONCE A CARTRIDGE IS INSTALLED, 0-50-0 CAN BE CLEARED FROM THE CNC USING THE ABOVE QUICK

RESTART COMMAND, OR MANUALLY BY CYCLING THE POWER SUPPLY ON/OFF SWITCH.

Loading...

Loading...