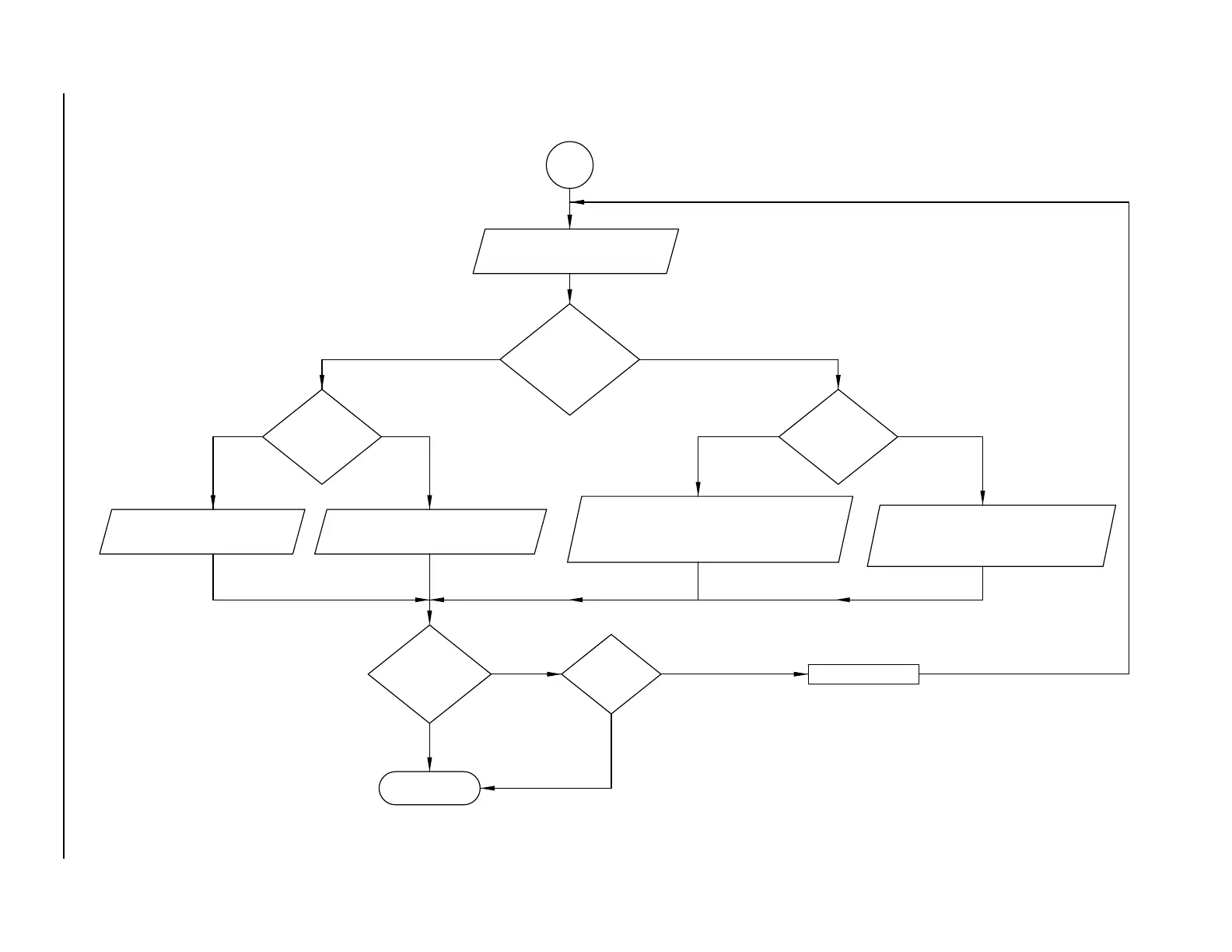

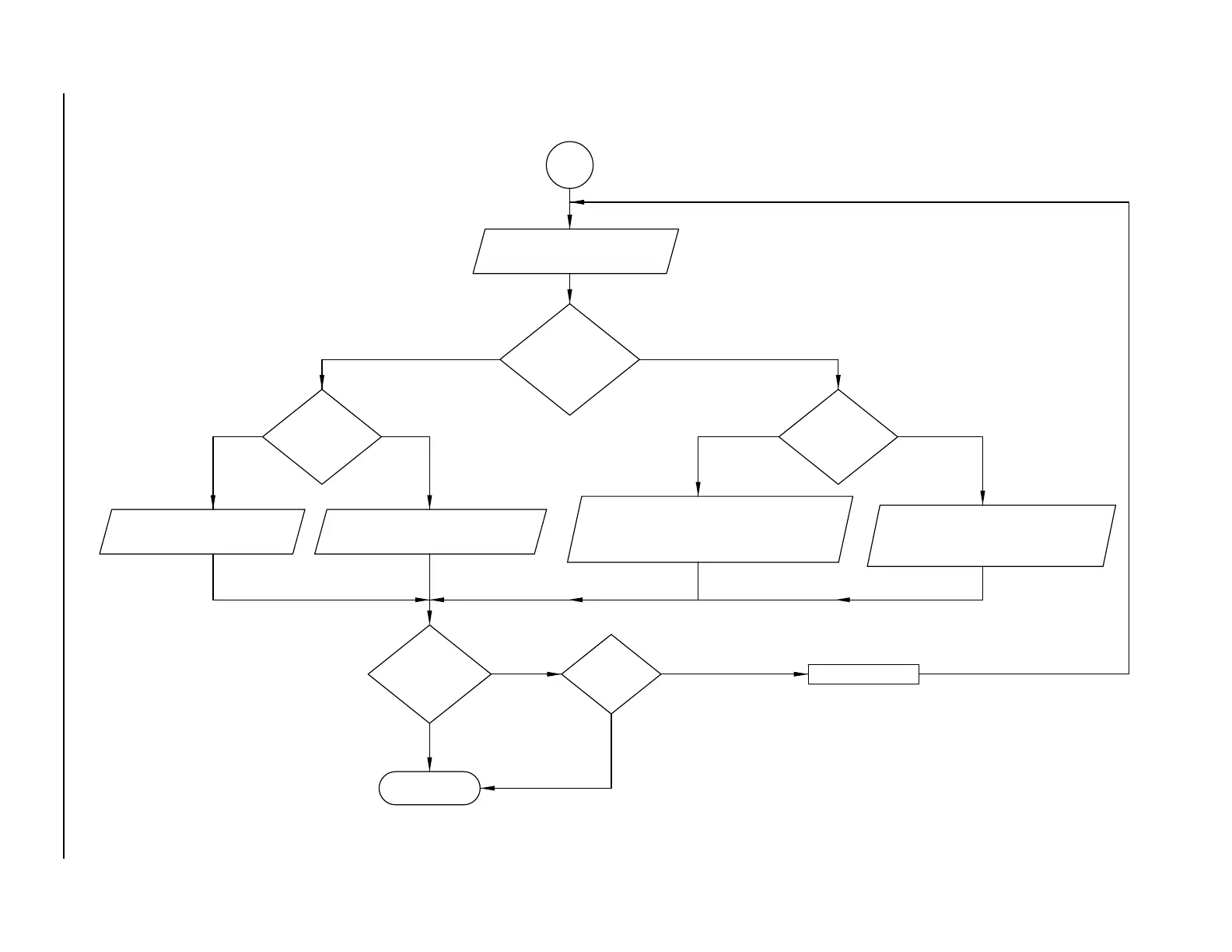

PRIOR SETTINGS ARE RETAINED,

NO NEED TO RE-SEND.

READ CARTRIDGE PART NUMBER.

REGISTER READ 0x3038-0x303A

SAME PART

NUMBER AS

PREVIOUS

CARTRIDGE?

NO

CHECK FOR

FAULT.

REGISTER READ

0x0301A

ALLOW

CYCLE

START

MINOR OR

MAJOR?

YES

PARAMETERS ARE AUTOMATICALLY SET

BASED ON THE NEW CARTRIDGE INSTALLED.

SYNC SETS NOMINAL MODE, CURRENT,

PRESSURE.

ENTER

SET POINTS

WRITE MODE, CURRENT, PRESSURE.

REGISTER WRITE 0x3080-0x3082

SET POINTS

POWER SUPPLY USES

PRIOR PARAMETERS

(CARTRIDGE NOMINAL OR

CNC SET).

USE CNC CUSTOM

PARAMETERS

SYNC SETS

PARAMETERS

CNC SETS NEW

CUSTOM PARAMETERS

NO FAULTS

0-00-0

POWER SUPPLY

OR MAJOR FAULT

MINOR FAULT,

OPERATION ALLOWED

FAULT

DETECTED

ENTER REMOTE CONTROL MODE BY

WRITING MODE, CURRENT, PRESSURE.

REGISTER WRITE 0x3080-0x3082

SYNC

FIX THE PROBLEM

Loading...

Loading...