Serial Communication Programmer Reference Guide

8 810400 Reference Guide Powermax65/85/105 SYNC

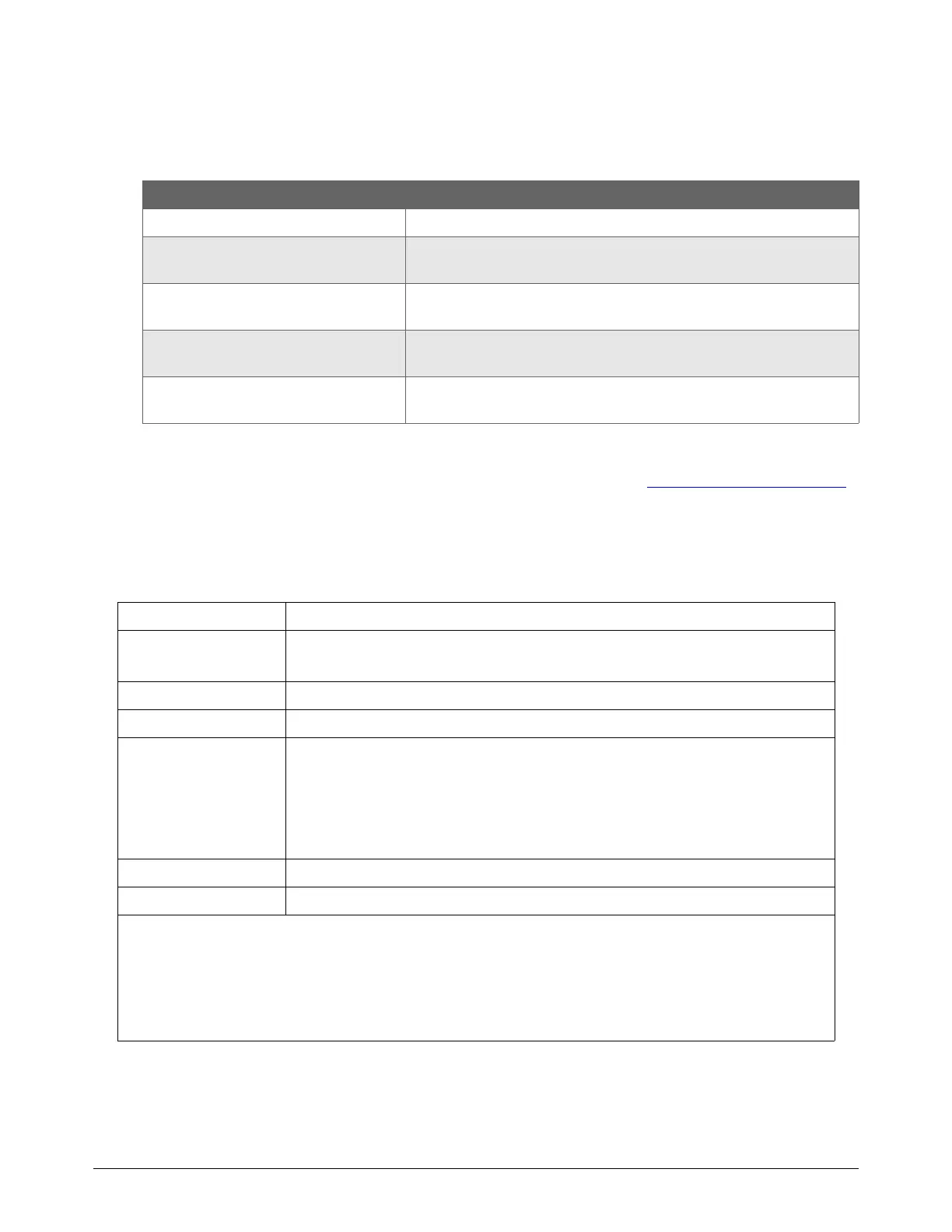

Powermax65/85/105 SYNC hardware documents

Refer to the following documents for more information about the required hardware for serial

communications.

You can find these documents on the USB memory stick that came with your plasma power supply,

or with the hardware kits. Technical documentation is also available at www.hypertherm.com/docs

.

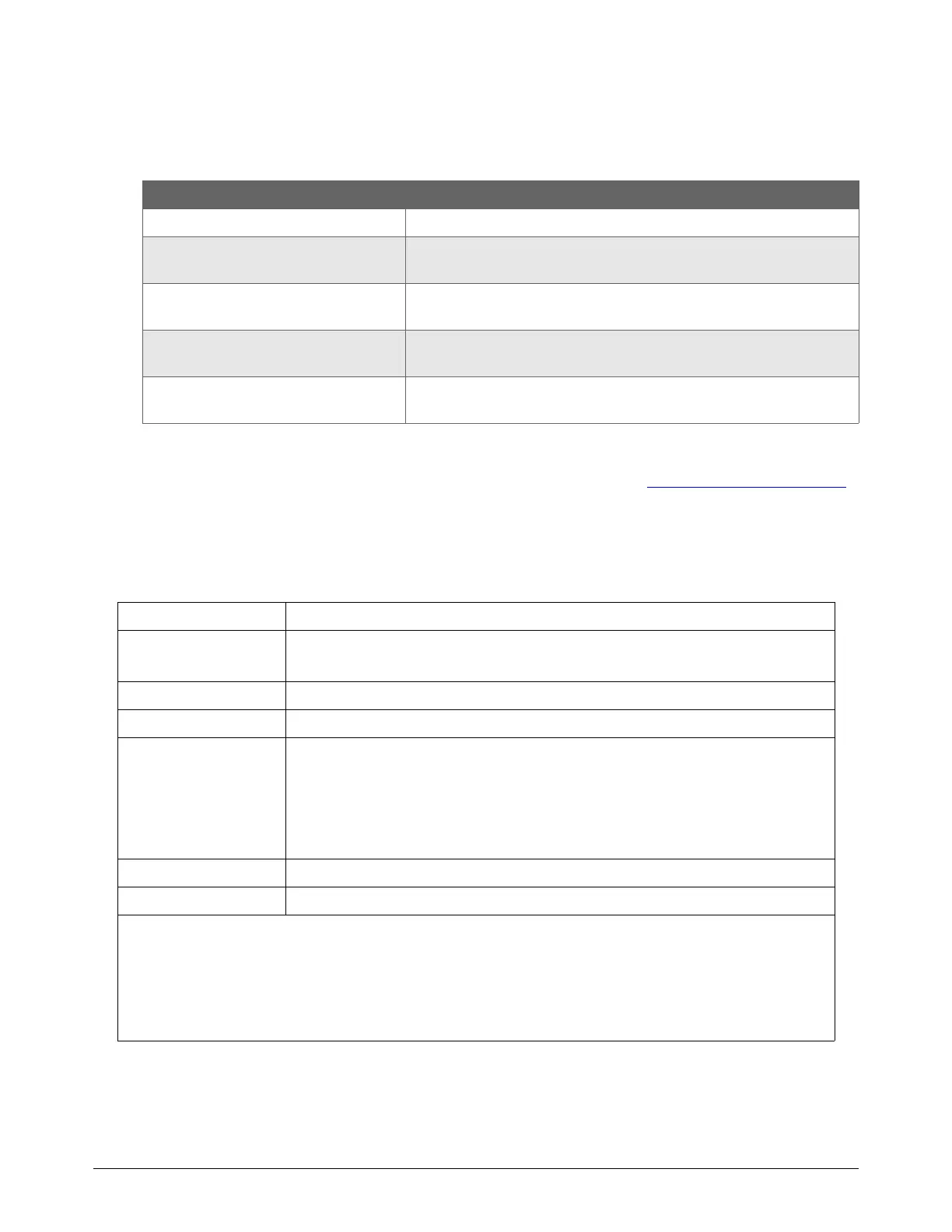

Modbus specifications

Transmission mode and format

How-to Information Document

Order hardware, kits, and cables Powermax65/85/105 SYNC Parts Guide (810490)

Attach a machine torch to a cutting

table

Powermax65/85/105 SYNC Mechanized Cutting Guide (810480)

Install an RS-485 serial interface

connector and board

RS-485 Serial Interface Connector with PCB Field Service

Bulletin (806710)

Install a machine interface receptacle

and voltage divider board

Machine Interface Receptacle with Voltage Divider PCB Field

Service Bulletin (806980)

Connect external serial interface and

machine interface cables

Powermax65/85/105 SYNC Mechanized Cutting Guide (810480)

Mode ASCII (American Standard Code for Information Interchange)

Addressing Controller: CNC

Connected device: Powermax65/85/105 SYNC

Coding system Hexadecimal, ASCII characters 0 - 9, A - F

Baud rate 19200

Bits per byte Start bit: 1

Data bits: 8

• Includes 1 bit for even parity

• Most significant byte (MSB) sent first

Stop bit: 1*

Parity Even**

Error-check field Longitudinal Redundancy Check (LRC)

* The stop bit setting on the plasma power supply and the external control must be the same. By default the

Powermax65/85/105 SYNC plasma power supply is set to 1 stop bit. Refer to CNC settings on the

Powermax65/85/105 SYNC on page 12.

** The parity setting on the plasma power supply and the external control must be the same. By default the

Powermax65/85/105 SYNC plasma power supply is set to Even parity. Refer to CNC settings on the

Powermax65/85/105 SYNC on page 12.

Loading...

Loading...