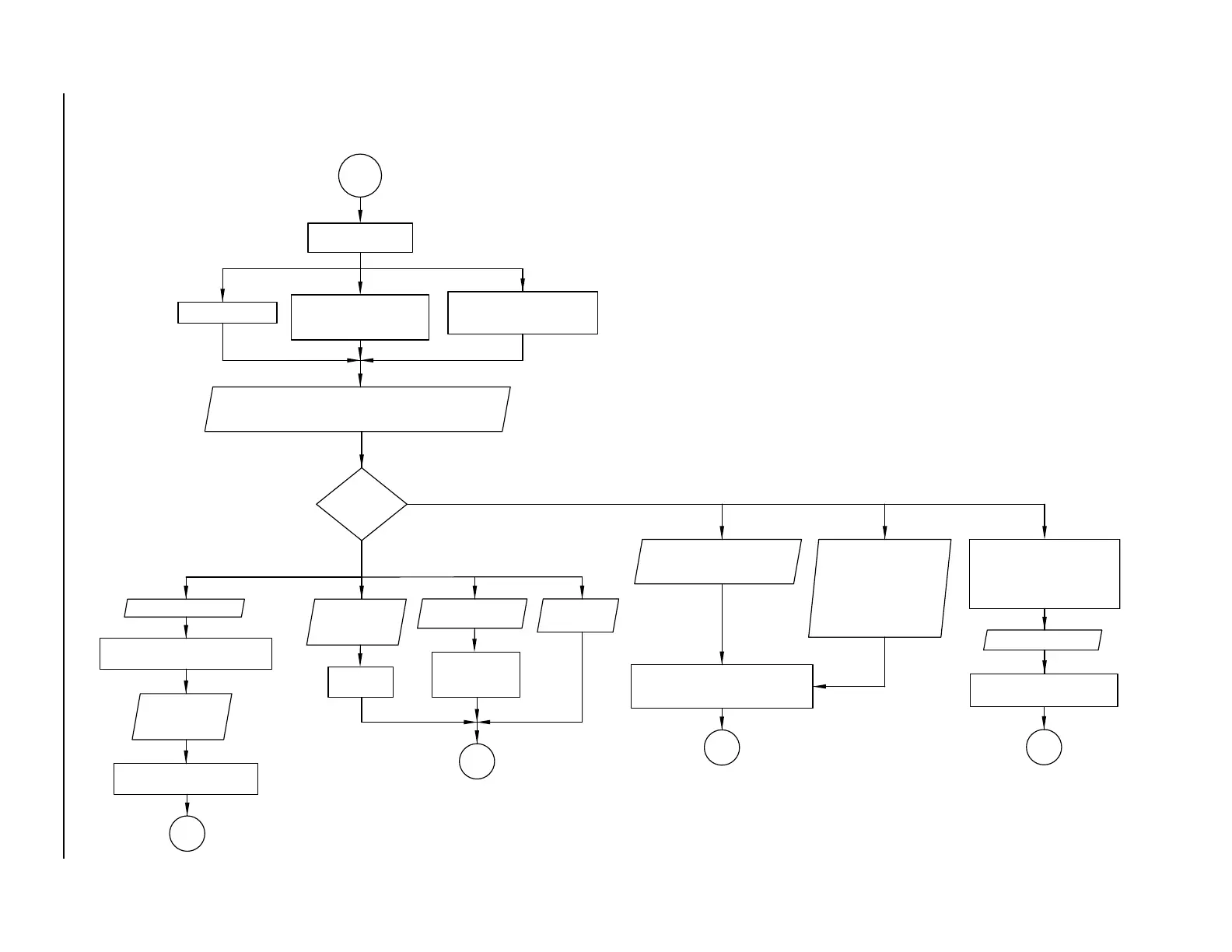

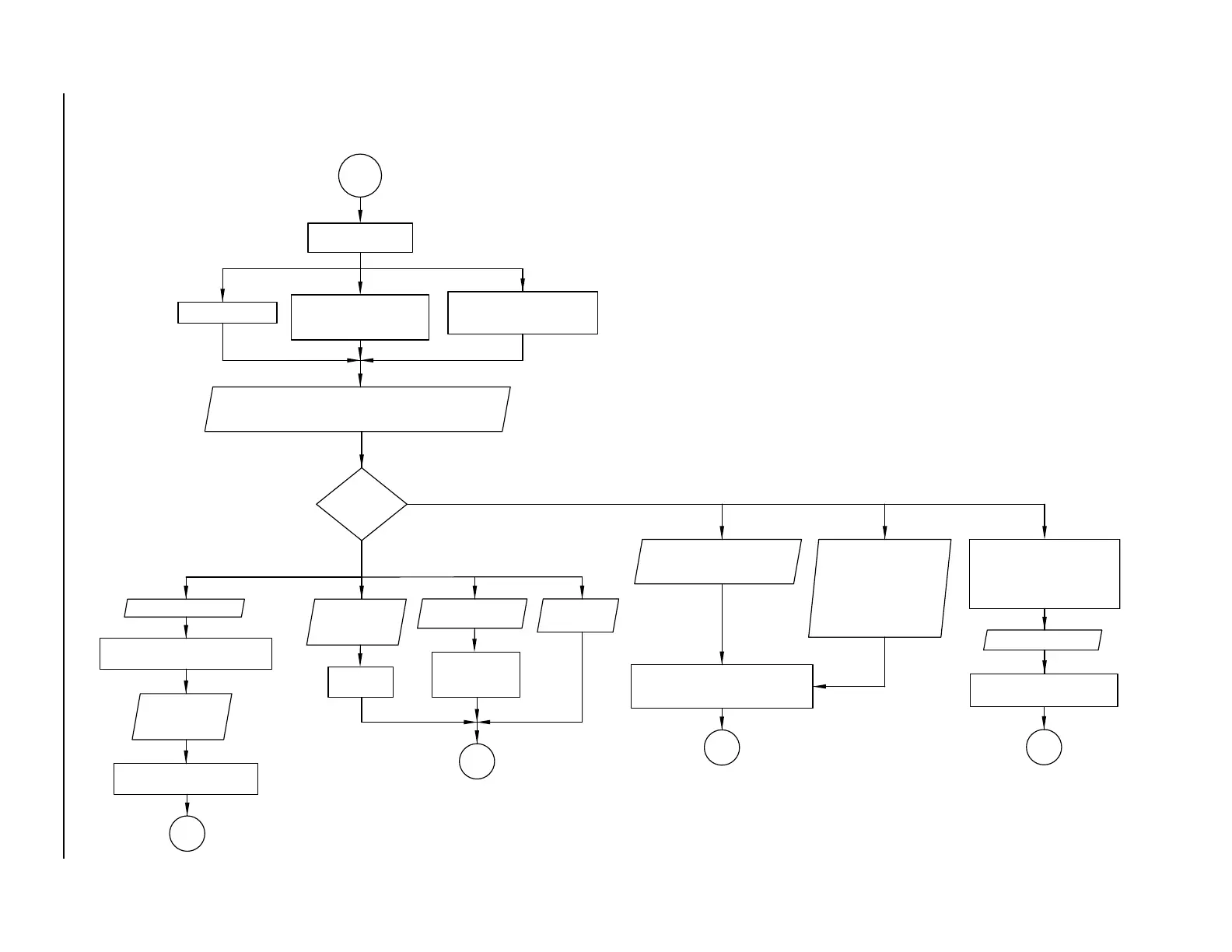

ENTER

FAULT 0-50-3 CARTRIDGE READ IN PROGRESS.

NORMALLY TAKES LESS THAN 1 SECOND, BUT CAN TAKE

UP TO 6 SECONDS IF RFID HAS DIFFICULTY READING.

YES

FAULT CODE

CLEARS

(FAULT 0-00-0)

NO

QUICK RESTART USING THE

MAIN POWER SWITCH OR

CNC COMMAND

COLD POWER ON

CARTRIDGE

READ OK

EXIT

CUT

ALLOWED

CUT ALLOWED

BUT NOT

RECOMMENDED

OTHER FAULT

CODES

FAULT CODE 0-32-1

CARTRIDGE EOL

MOVE THE LOCK SWITCH

TO THE UNLOCKED

POSITION

SEE 0-14-0 FAULT FLOWCHARTS

FOR HAND OR MECHANIZED,

TORCHES

2ND TRIGGER PULL, CUT

ALLOWED

1ST TRIGGER PULL, WARNING

PUFFS OF AIR, NO ARC

EXIT

FAULT CODE 0-50-2

HAND TORCH

ONLY

EXIT

FAULT CODE

CLEARS

(FAULT 0-00-0)

MINI/ROBOTIC TORCH

AFTER A QUICK RESTART

FAULT CODE

0-14-1

OR 0-98-1

OR 0-98-2

0-50-0 FAULT CODE

EXIT

MINI/ROBOTIC TORCH.

USER FORGETS TO POWER

OFF THE POWER SUPPLY

BEFORE CHANGING THE

CARTRIDGE

QUICK RESTART BY

USER OR CNC REQUIRED

USER INSTALLS A

NEW CARTRIDGE

FAULT CODE 0-14-0

CARTRIDGE CANNOT SEND

DATA TO THE POWER SUPPLY

NOTE: FOR MECHANIZED AND MINI TORCH INSTALLATIONS, SOME FAULT

SCENARIOS PREVENT 0-50-3 FROM DISPLAYING DURING THE CARTRIDGE READ.

SYNC

Loading...

Loading...