41

/

2. Wiring

2.4 Wiring Method

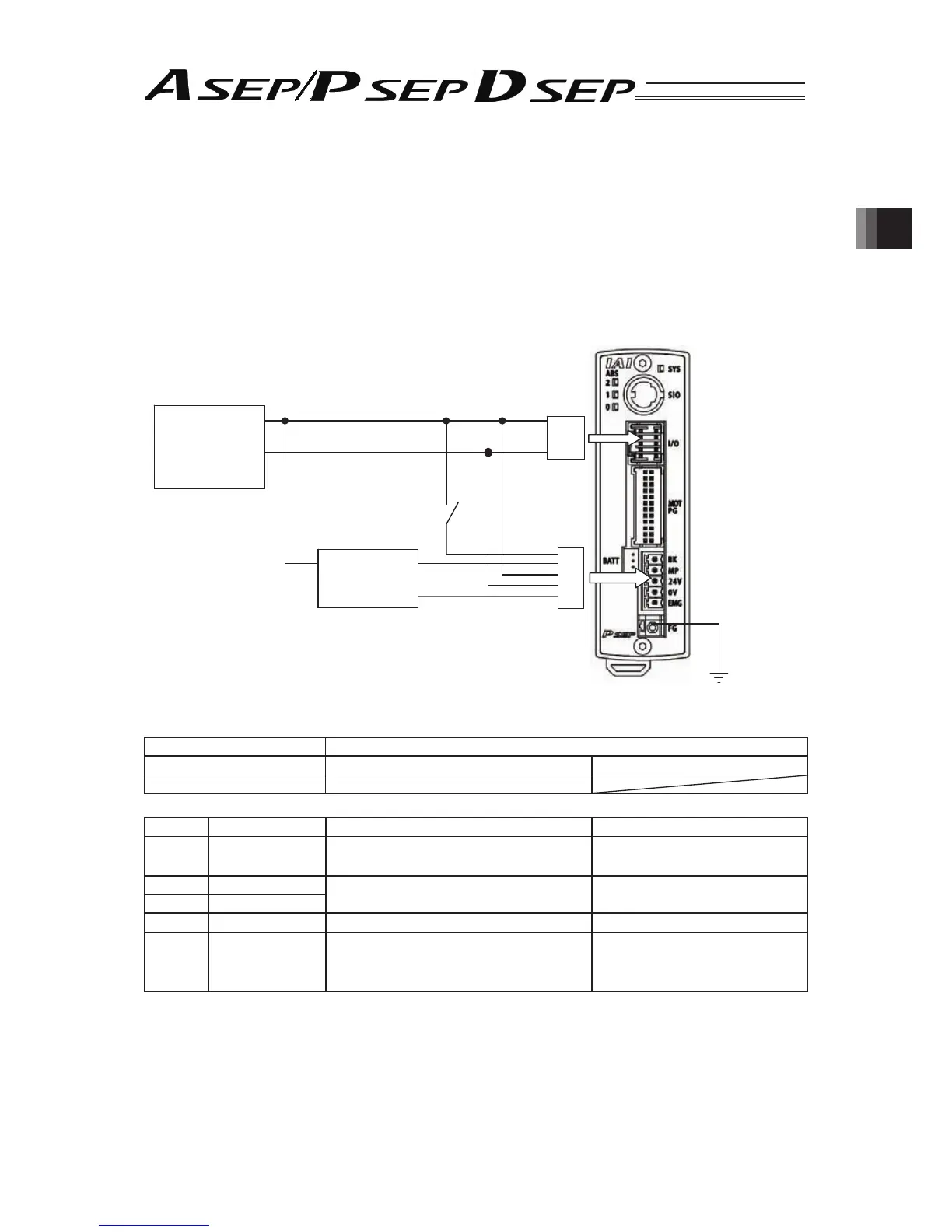

2.4.1 Wiring Layout of Power Supply Connector

The wires of the power supply and the emergency stop circuit are to be connected to the enclosed

connector (plug).

trip the sheath of the applicable wires for 7mm and insert them to the connector. Push a protrusion

beside the cable inlet with a small slotted screwdriver to open the inlet. After inserting a cable, remove

the screwdriver from the protrusion to fi x the cable.

24V DC

Power

Supply

+

24V

0V

Brake Release

Switch

(Turn ON to

Release Brake)

1 Pin

(BR)

2 Pin

(RD)

(MC1.5/5-ST-3.5)

Accessory I/O

Flat Cable

Emergency

Stop Circuit

[Refer to 2.3]

Accessory Power

Supply Connector

Class D Grounding

● Power Supply Connector

Connector Name -

Cable Side MC1.5/5-ST-3.5 Standard Accessory

Controller Side MC1.5/5-G3.5

Pin No. Signal Name Contents Applicable Wire Diameter

1 EMGIN

Input of Emergency Stop

Status Signal

(Note 1)

KIV0.5mm

2

(AWG20)

20V

Power Supply Input (24V DC ±10%) KIV1.25mm

2

(AWG16)

3 24V

4 MP Motor Driving Power Supply Line KIV1.25mm

2

(AWG16)

5BK

Brake Forced Release Power Supply

Input

(Note 2)

(24V DC ±10% 150mA)

KIV0.5mm

2

(AWG20)

(Note 1) The emergency stop status signal input determines as the system is in normal condition when 24V

DC is input and in emergency stop when 0V is input. Once in emergency stop, the actuator stops its

operation and turns the servo off.

Construct the emergency stop circuit suits for the safety category considering the entire system.

(Note 2) The brake is compulsorily released when +24V is supplied. Make the 0V in common with the 0V of the

power input. Do not apply on DSEP.

Loading...

Loading...