104 Intermec EasyCoder PF2i, PF4i, and PF4i Compact Industrial—Service Manual

Chapter 7—Print Mechanism

In many cases, it is desired to start the printing immediately at the top

of the label. Actually, what you want to do is to pull back the edge of the

media to the dot line. You can do this by means of a negative Start Adjust

value (for example -100 dots = 12.5 mm/0.49 inches). Be careful not to

enter too large a value, or the media may come loose from platen roller.

When using peel-off operation, the labels would drop from the liner and

get stuck on for example the desk if you use the default Start Adjust value

0. Use a Stop Adjust value of around -44 (= 5.5 mm/0.22 inches) instead:

that is, after the printing is completed 5.5 mm/0.22 inches less of media

feed than normal will be performed. However, if you still want to print

from the top of the label, you must compensate by a Start Adjust value of

around -56 (= 7.0 mm/0.28 inches). Note that the sum of the Start and

Stop Adjust values always is 100 dots (12.5 mm/0.49 inches), which cor-

responds to the distance between dot line and tear bar minus a margin for

the gap between labels and certain slippage.

A special case is tickets with black marks. It is recommended to place the

black mark adjacent to the perforation or the intended tear-off line. If the

black mark is placed further down the media, this must be compensated

for by a negative Stop Adjust setting.

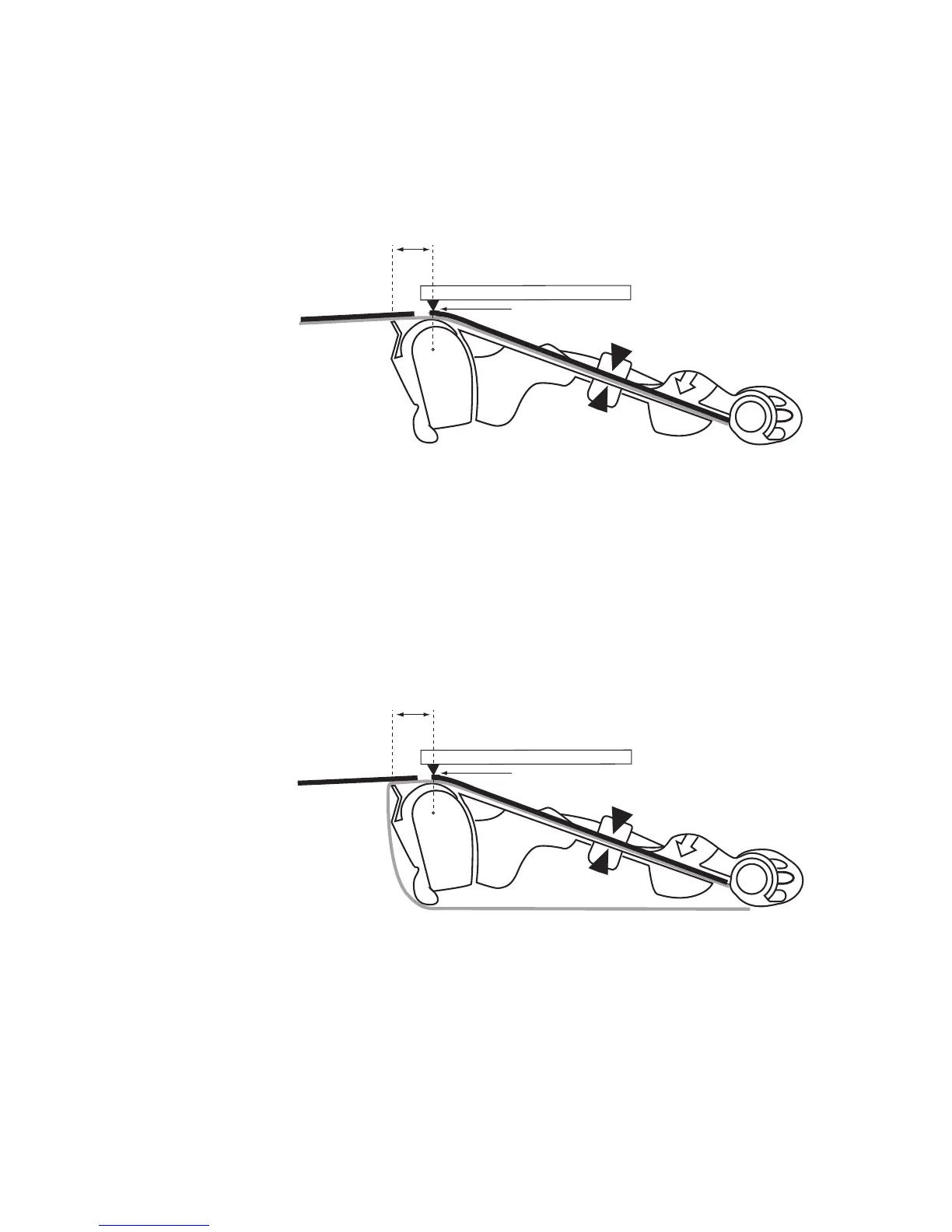

Label Stop

Sensor

Dot Line on Printhead

14.4 mm

Tear off (print at top of label):

Start Adjust: -100

Stop Adjust: 0

Tear Bar

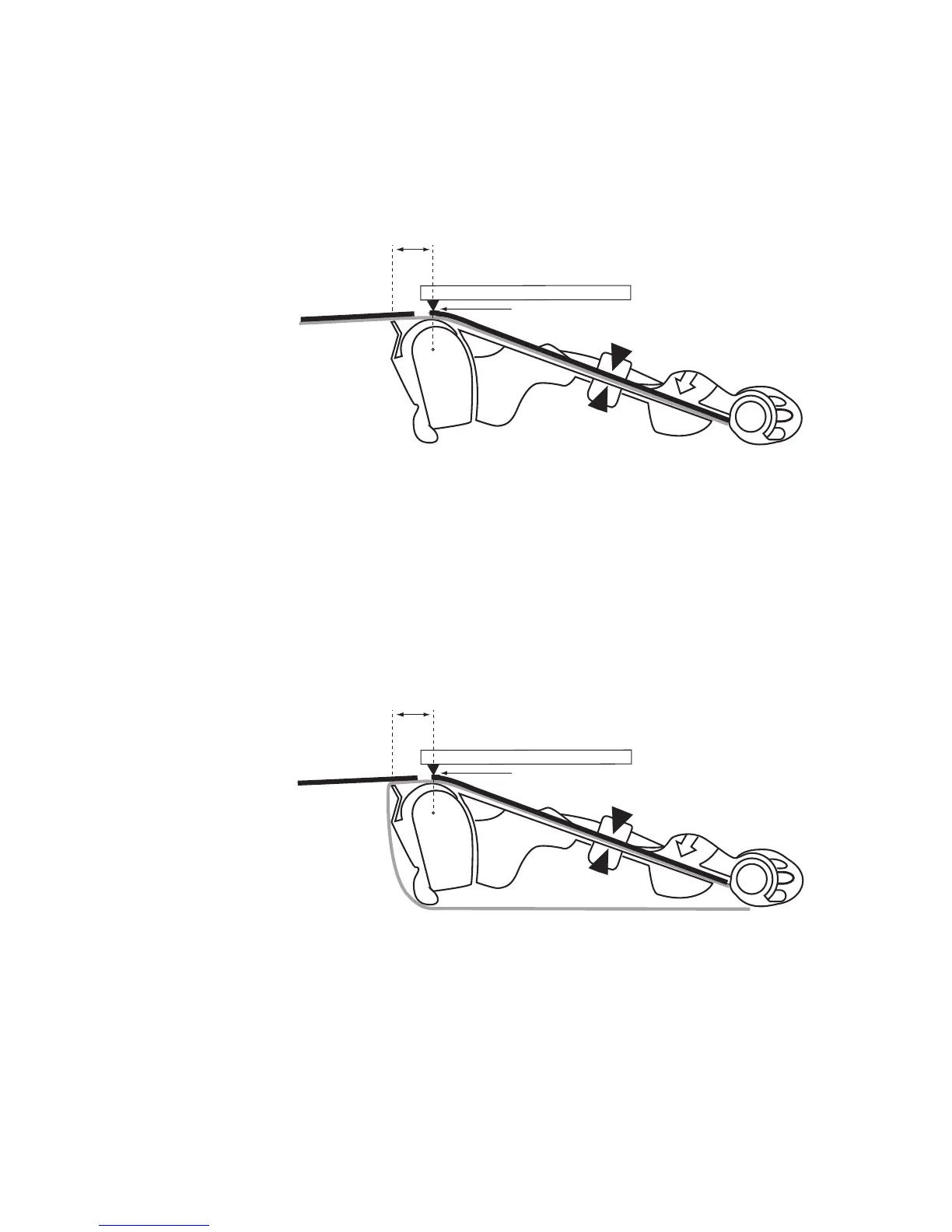

Label Stop

Sensor

Dot Line on Printhead

14.4 mm

Peel off (print at top of label):

Start Adjust: -56

Stop Adjust: -44

Tear Bar

Loading...

Loading...