SCMA54&SCMA48

82

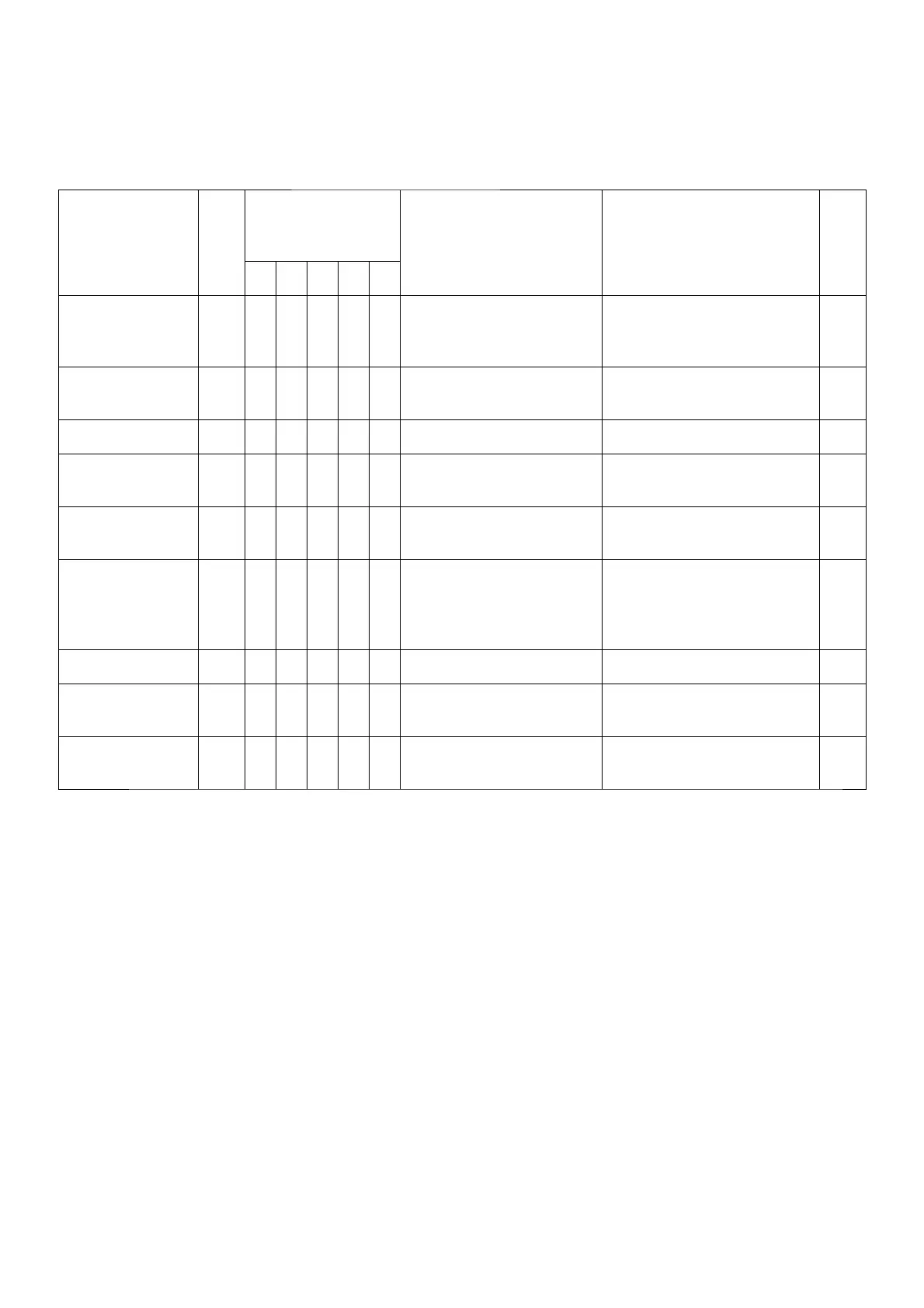

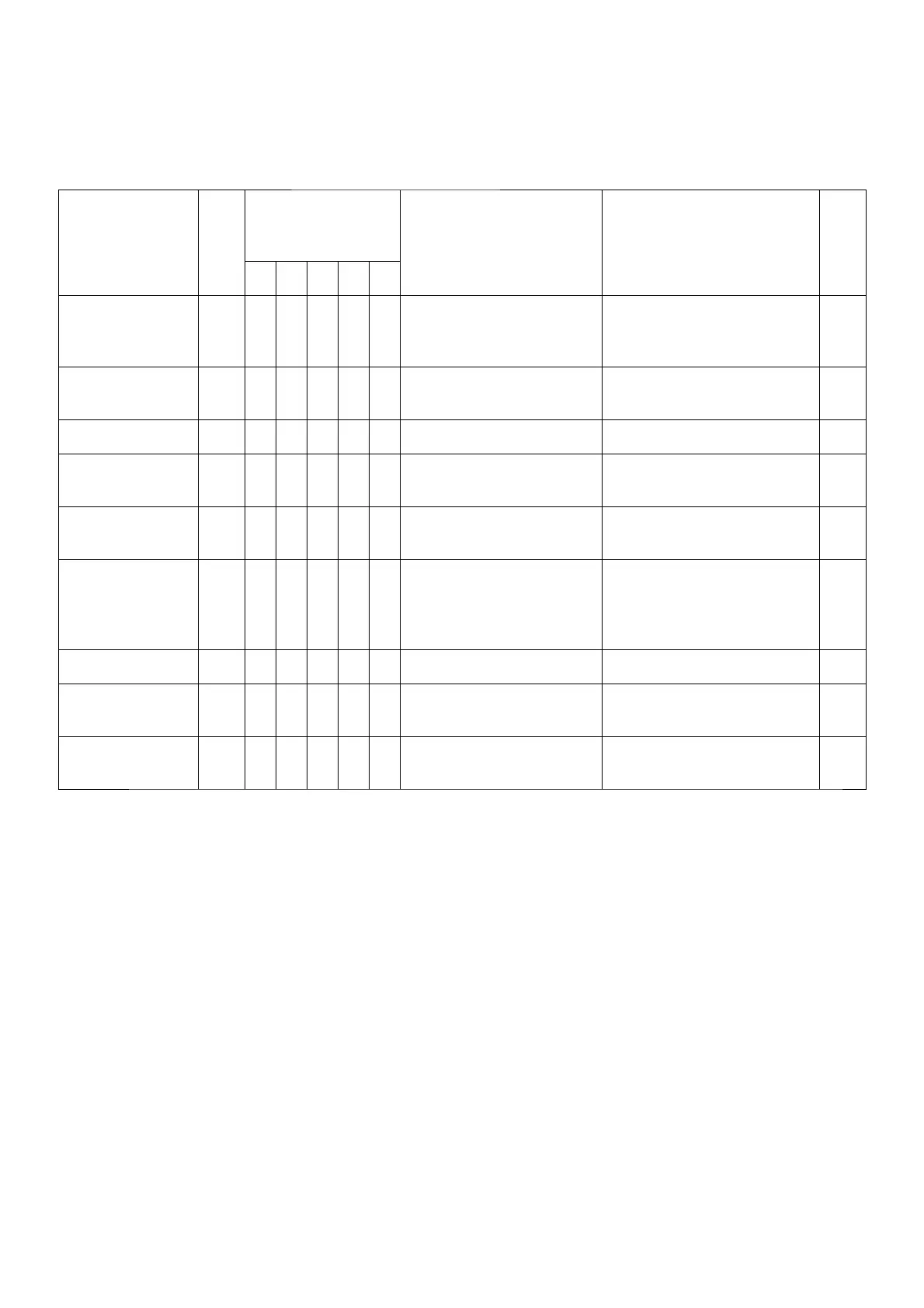

8. PERIODICAL INSPECTION TABLE

○

:Inspection, replenishment, and adjustment △ : Cleaning and washing

●

: Replacement ★ : Consult your dealer.

Check points

Pre-

operation

Inspection and

servicing intervals

(hours of operation)

Intervals after that Judgement criteria

Ref.

page

50 100 150 200 250

Blade

○

"Deformed, broken, worn,

and cracked ones shouldbe

replaced."

71

Bevel gear case

(LH) and (RH)

●○○○●

Replace after initial 50 h.

and then after every 200 h.

Maintain the specifiedlevel. 69

Belt tension

○

Spring coil clearance 70

Roller and gauge

wheels

○

They should turn smoothly. 72

Belt cover inside

△△△△△

Clean after every 50 h.

There should be no grassor

dust accumulated.

70

Belt

○○○○○

Clean after every 50 h.

Criteria for replacement:

・Deep crack over half the

thickness of belt.

・Worn out side wall canvas

70

Greasing points

○○○○○

Grease up after every 50 h. 73

Bolts and nuts

○

There should be no loose

ones.

-

Pins and crips

○

There should be no lost or

deformed ones.

-

Important:

・ Above mentioned service intervals should be used as reference creteria. If working conditions are harder, earlier

service is recommended.

・ When special technology and special tools are required, consult your dealers.

Loading...

Loading...