Instructions for use ELECTROmatic TM and TMM/TMC

10 Troubleshooting

10 Troubleshooting

Note

This product displays error messages and/or instructions optically on its dis-

play.

The motor is shut off in any case of malfunction.

▶ If the error message does not disappear or the error is reported again, con-

tact Service.

▶ Restart the unit with all the other error messages.

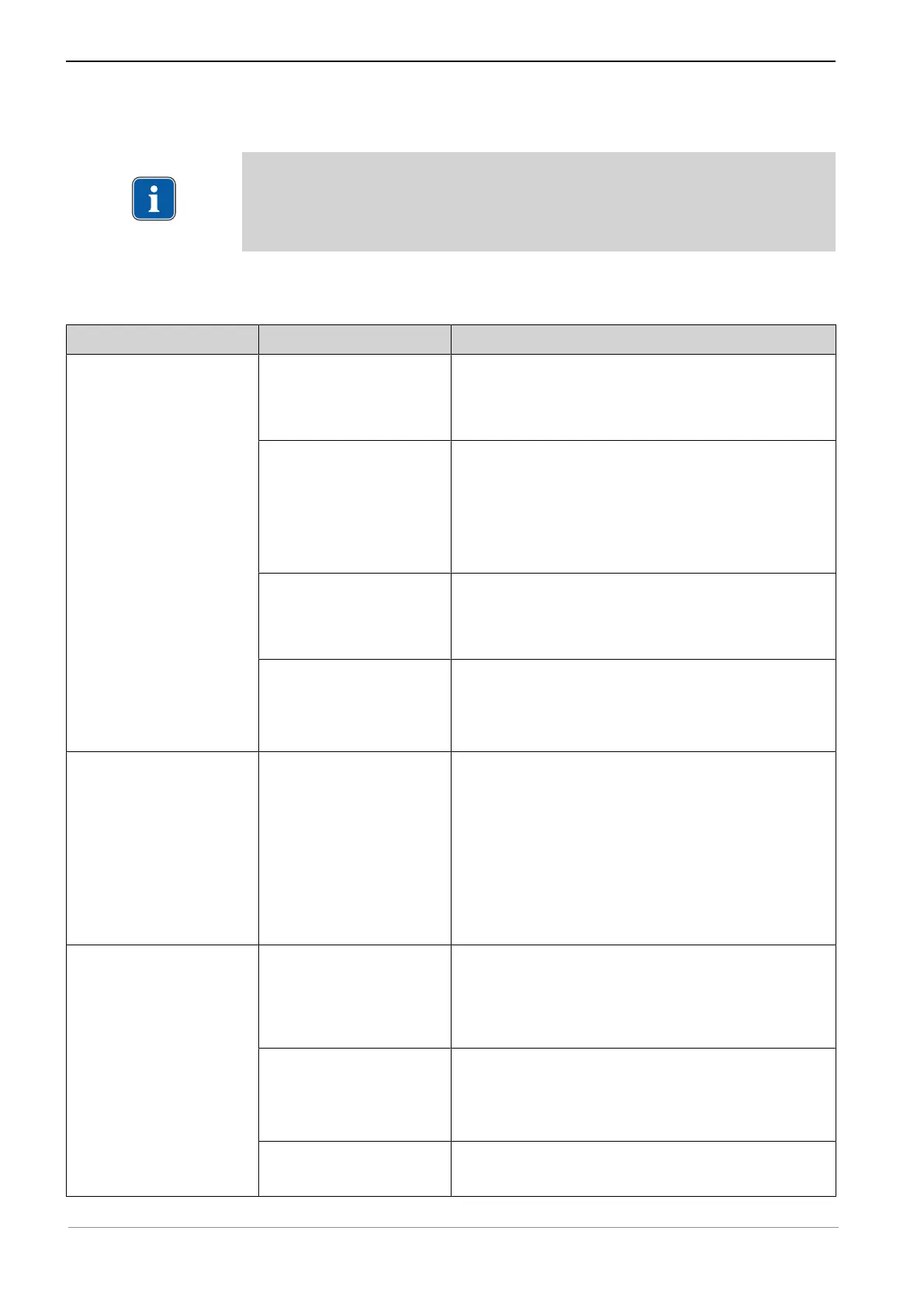

Malfunction Cause Remedy

No or insufficient spray

water.

Spray water regulation

is closed.

▶ Open the spray water as much as possible.

See also:

2 6.3 Regulating the spray water, Page 56

Water line is soiled.

▶ Open the spray water as much as possible.

See also:

2 6.3 Regulating the spray water, Page 56

▶ Pull the handpiece off and actuate the spray

water in bursts (rinsing process).

Filter insert is soiled.

▶ Replace filter on water inlet.

See also:

2 9.1 Changing the filter - water inlet, Page 77

Spray water on treat-

ment centre or foot

control is closed.

▶ Open the spray on the treatment centre.

▶ If the error persists, unscrew the turbine hose

and check if any water flows.

▶ If no water flows, notify a service engineer.

Device malfunctions

(no display, the LED on

the rear of the device

does not flash).

No voltage supply.

▶ Check/restore correct voltage supply and cor-

rect connection.

ð The standby LED on the power supply is on.

See also:

2 3.8 Power supply type 4882, Page 31

▶ If the standby LED on the power supply is not

on, replace the power supply.

▶ If error persists, notify the service engineer.

Maximum speed not

reached.

Supply pressure

dropped strongly.

▶ Repeatedly push the foot control down as far

as it will go.

ð The motor starts-up during this process. The

automatic calibration increases the speed con-

tinuously up to the maximum pressure.

Kink or leak in supply

hose.

▶ Remove the kink and check for damage!

▶ In case of damage/leakage, replace the supply

hose.

▶ If error persists, notify the service engineer.

Motor and/or handpiece

are sluggish.

▶ Replace or repair handpiece.

▶ If error persists, notify the service engineer.

81 / 90

Loading...

Loading...