Manufacturing calibration

The manufacturing calibration procedure is normally performed only at the factory, but the

necessary steps are included here in case the unit is repaired, and the unit requires these

calibration procedures.

NOTE If the unit has been repaired, the entire comprehensive calibration procedure should

also be performed in addition to the manufacturing calibration procedure.

Firmware revision level

The manufacturing calibration procedure depends on the firmware revision level, either

revision A13 and lower, or revision A14 and higher. The instrument displays the firmware

revision as part of the power-up cycle. Be sure to use the correct procedure as outlined below.

Recommended test equipment

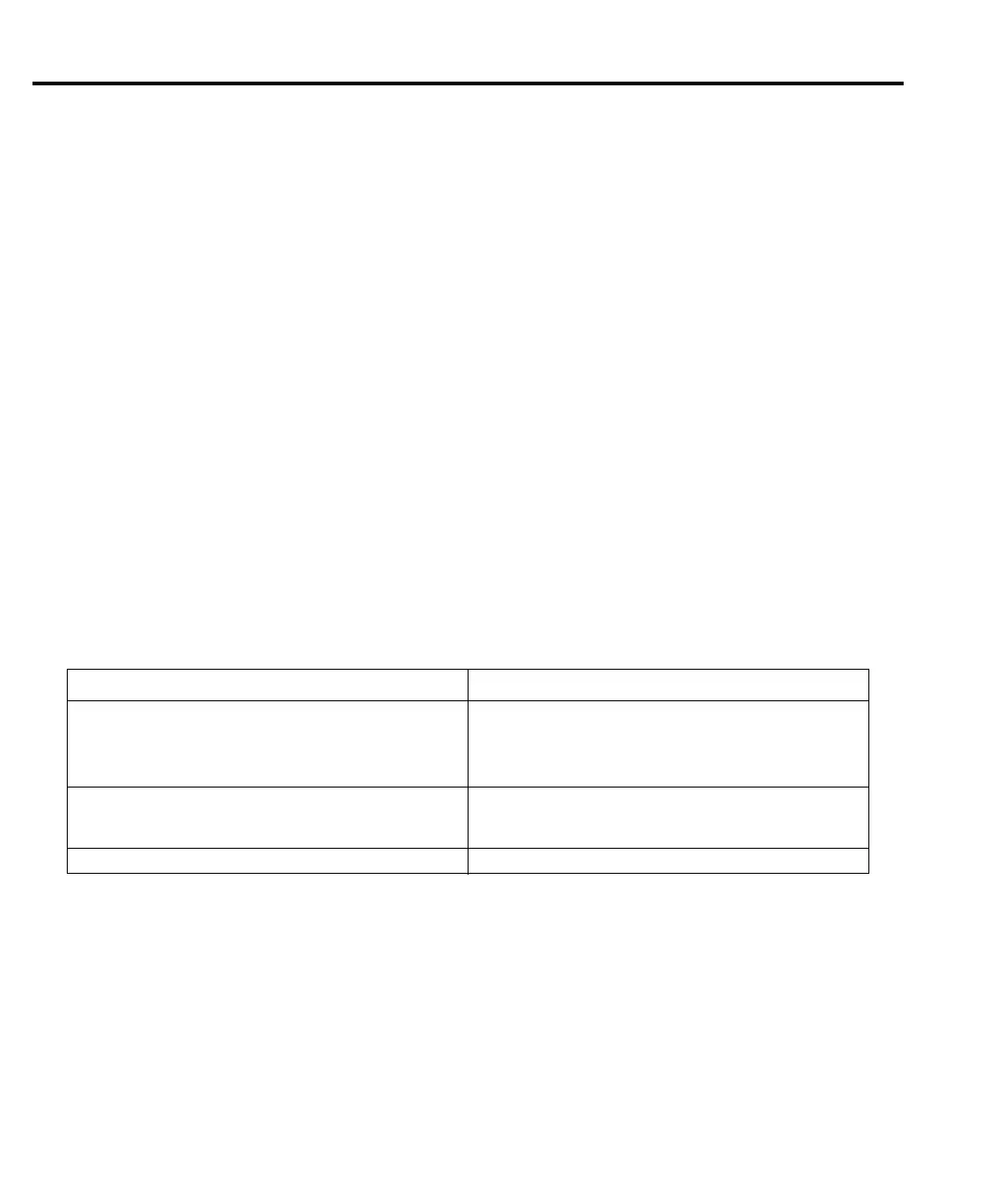

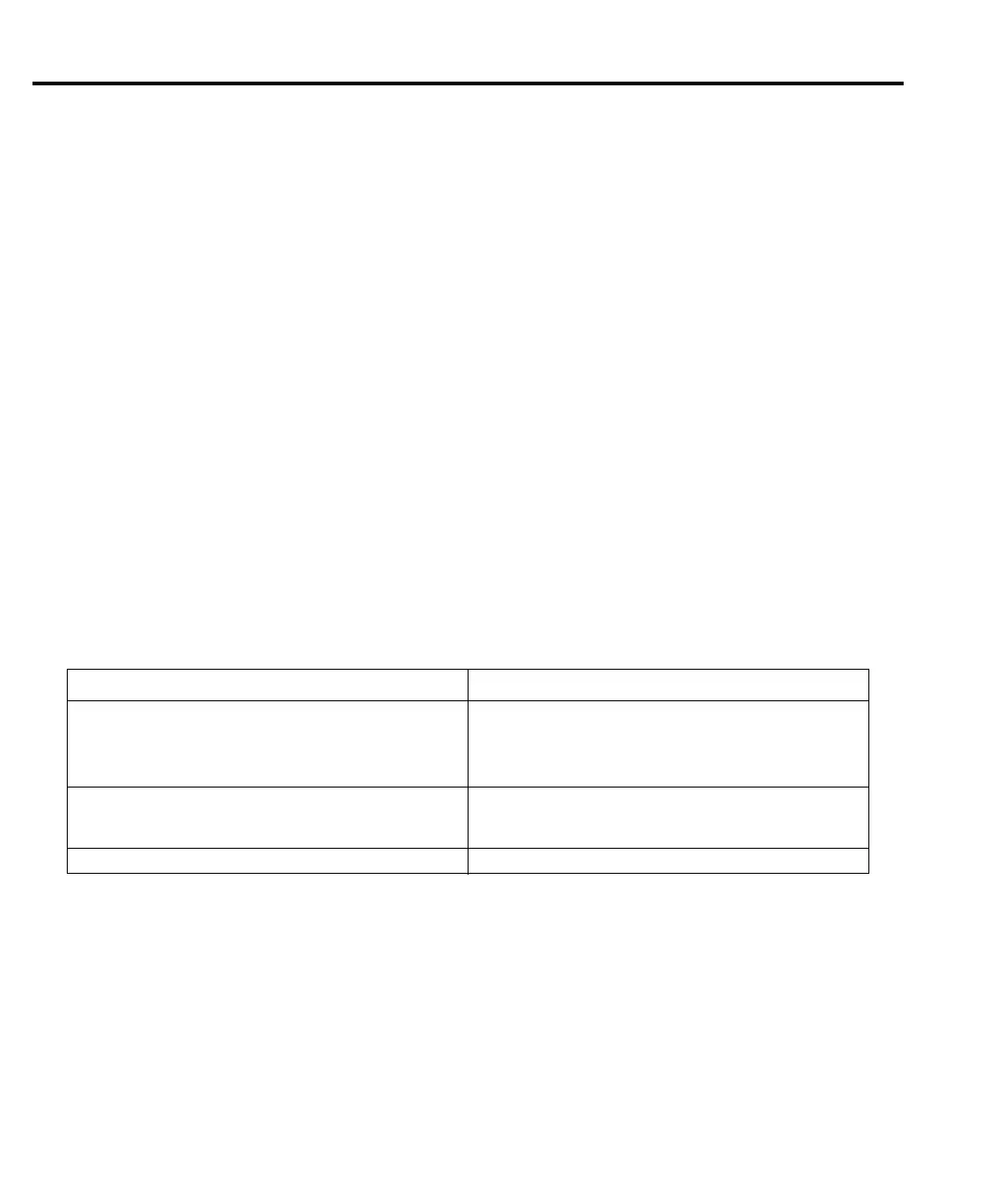

Table 2-13 summarizes the test equipment required for the manufacturing calibration steps.

Note that the equipment depends on firmware revision level. See Table 2-1 for equipment

necessary for the comprehensive calibration steps.

Table 2-13

Recommended equipment for manufacturing calibration

Firmware revision A13 and lower Firmware revision A14 and higher

Keithley 3930A or 3940 Frequency Synthesizer:

1V RMS, 3Hz, ±5ppm

1V RMS, 1kHz, ±5ppm

Stanford Research Systems

DS 345 Function Generator:

1V RMS, 1kHz, ±5ppm

Keithley Model 2001 or 2002 Digital Multimeter:

1V, 3Hz AC, ±0.13%

Fluke 5700A Calibrator:

1V RMS, 10Hz, ±260ppm

Keithley Model 8610 Low-thermal short Keithley Model 8610 Low-thermal short

2-20 Calibration

Loading...

Loading...