Model 6220/6221 Reference Manual Applications E-3

Return to Appendix topics

Resistivity measurements

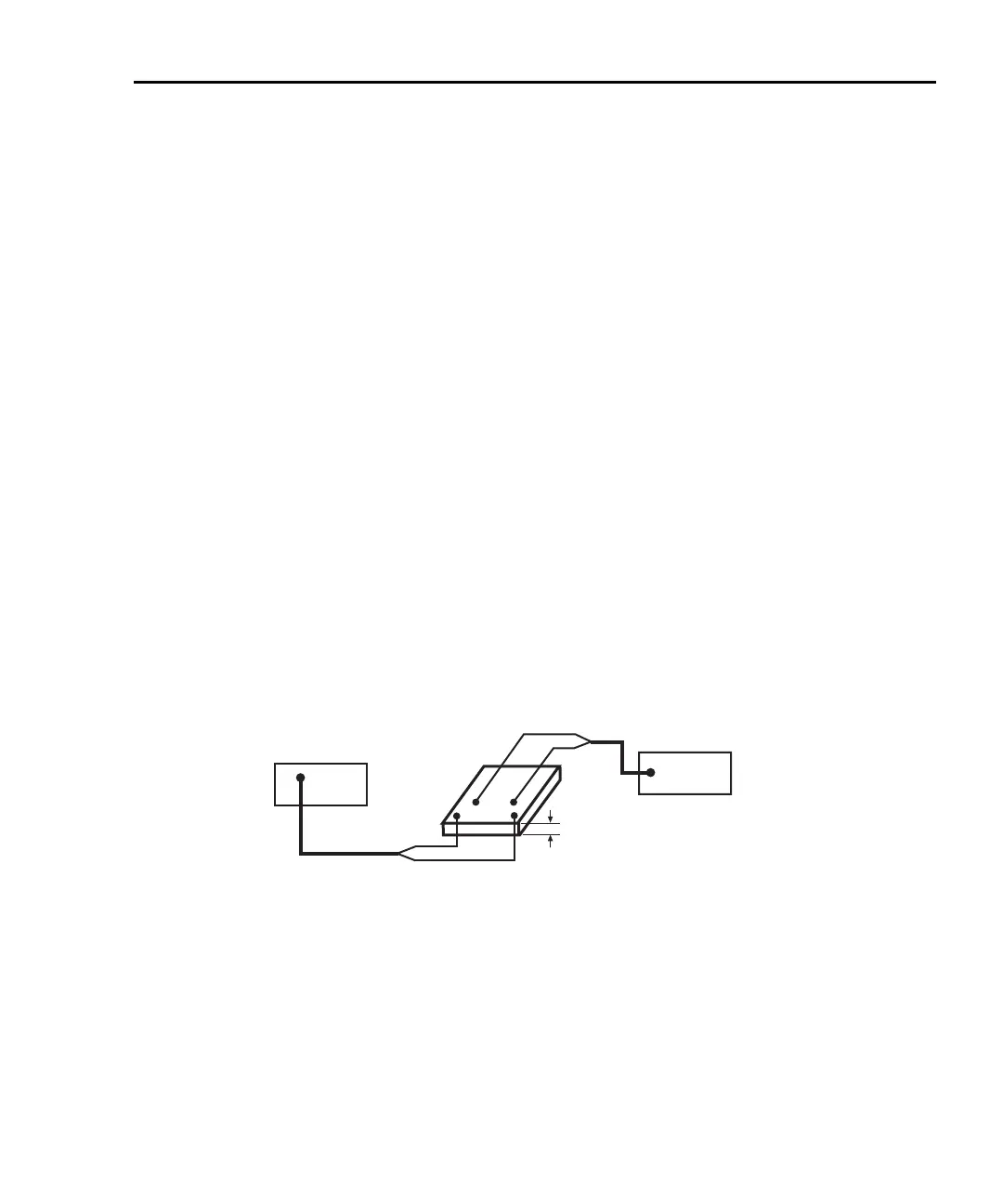

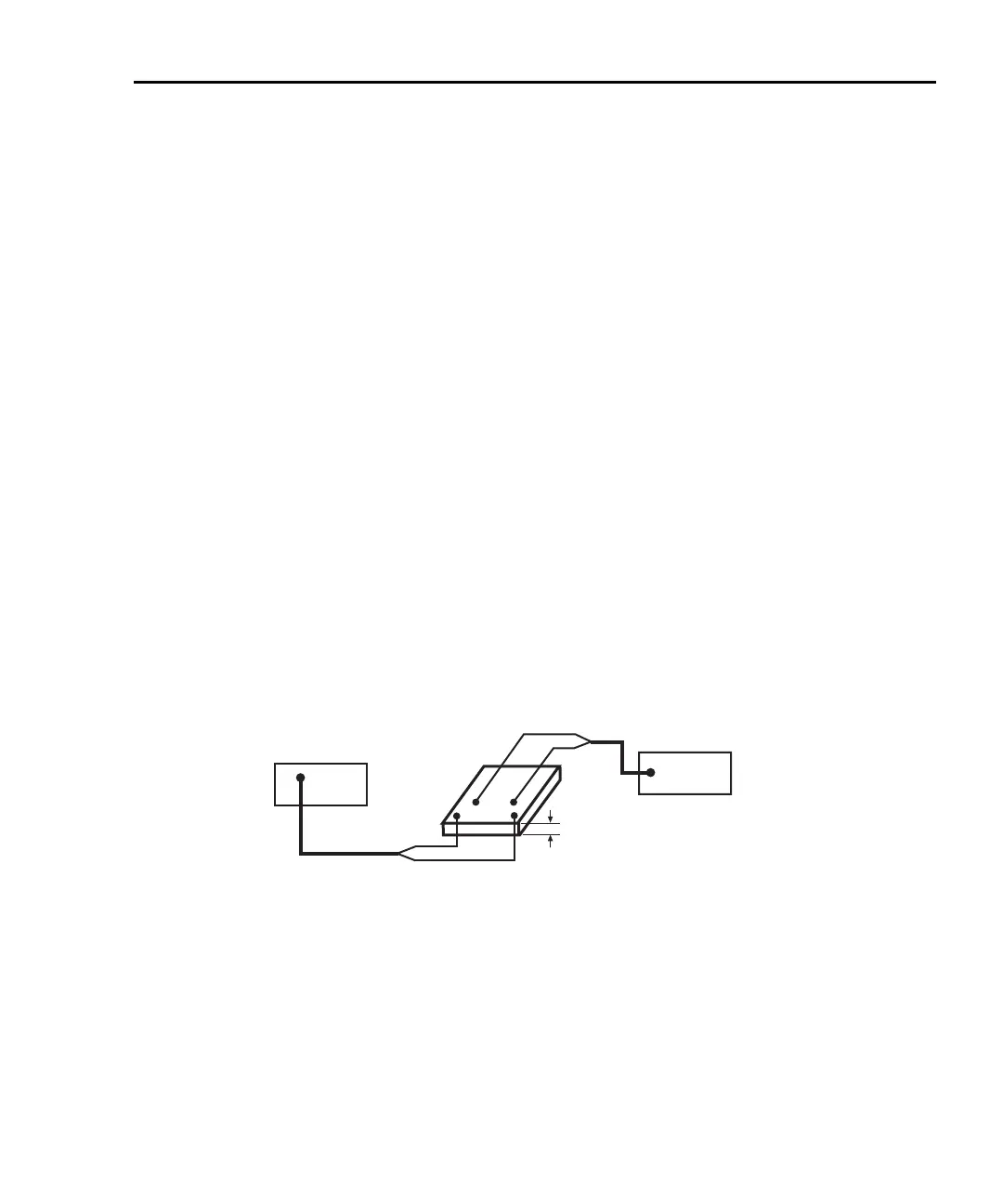

Certain semiconductor materials such as silicon have high resistivities. The mea-

surement of their resistivity can be a difficult measurement. To aid in the measure-

ment, special probes of a hard metal such as tungsten are used. Because contact

resistance is so high, a four point probe is usually employed. The outer two con-

tacts supply a constant current, and the inner two contacts measure the voltage

drop across a portion of the sample. With the geometry of the probe and wafer

known, resistivity can then be calculated.

The current source used must be stable and accurate. The Model 622x is ideal for

this application. The accurate and stable current along with compliance voltage

can be easily programmed before making the voltage measurement.

The electrometer requires a high impedance to overcome lead resistance prob-

lems. The Keithley Model 6514 Electrometer has the high input impedance

(>200TΩ in parallel with 20pF) required to make the measurement accurately. A

simple test system to measure resistivity is shown in Figure E-1.

For most wafers the resistivity is calculated from: P = ktV/ I

Where: k is a constant based on the geometry of the wafer and probe.

t is the sample thickness.

V is the measured voltage.

I is the current in the sample.

Figure E-1

Resistivity measurement test system

622x

Current Source

6514

Electrometer

t

Sample

Input

Output

Hi

Hi

Lo

Lo

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176 - TestEquipmentDepot.com

Loading...

Loading...