Fig.4-4 Wiring of analog output

Notes:

1. When using analog input, a filter capacitor common mode inductor can be installed between signal input

and GND

2. The analog input voltage is better under 15V.

3. Analog input and output signals are easily disturbed by noise, so shielded cables must be used to transmit

these signals and the cable length should be as short as possible.

4. The analog output terminal can stand the voltage under 15V

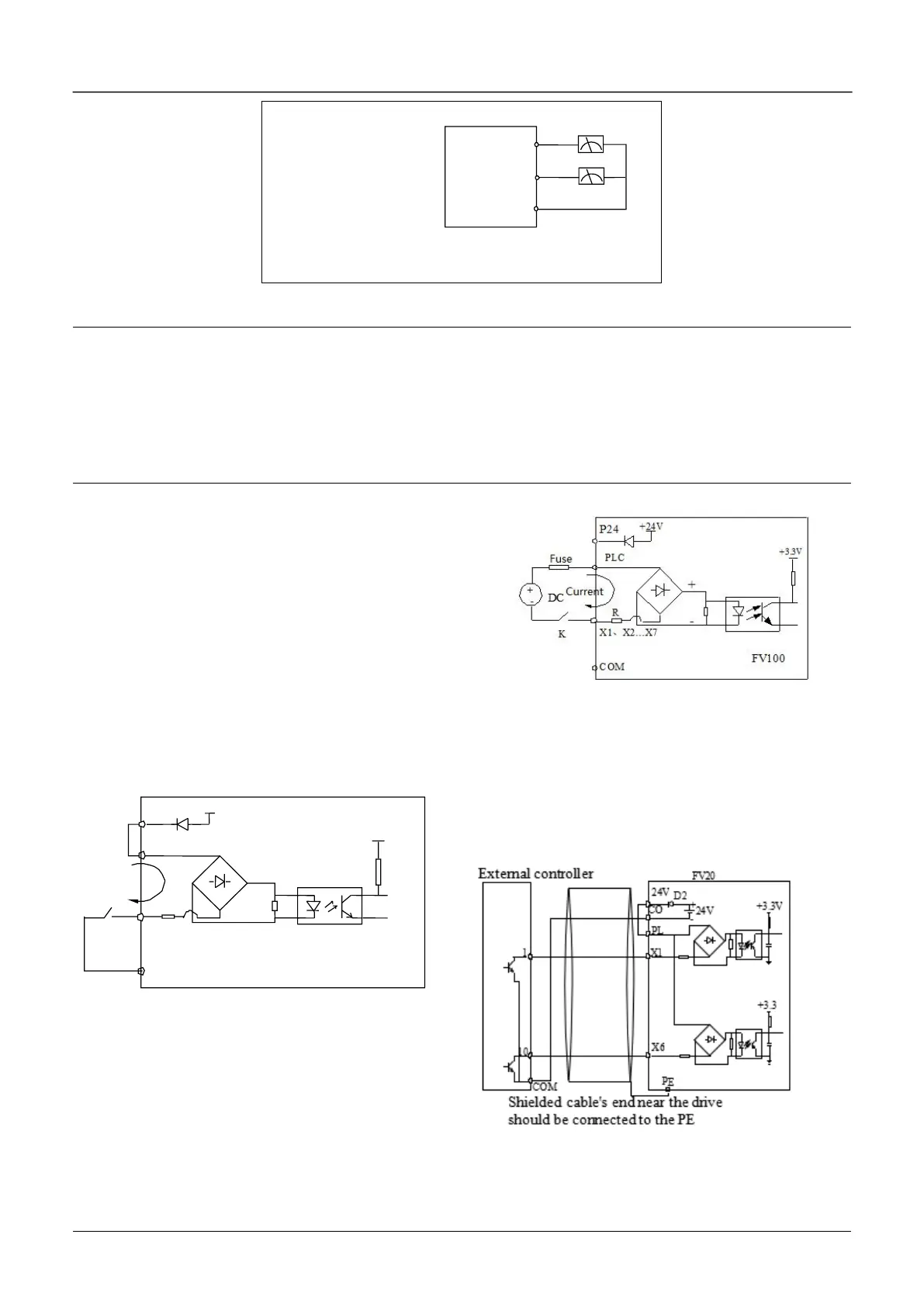

Wiring of multiple function input terminal and

operation terminal

FV20 multi-function input terminal uses a full-bridge

rectifying circuit as shown in Fig.4-7. PLC is the

common terminal of terminals X1~X6, The current

flows through terminal PLC can be pulling current

and the feeding current. Wiring of X1~X6 is flexible

and the typical wiring are as follows:

1. Dry contacts method

1) Use the internal 24V power supply of VFD, the

wiring is as in fig.4-7.

Fig.4-7 Wiring method of using the internal 24V power

supply

2) Use external power supply, (The power supply

must satisfy the UL CLASS 2 standard and a 4A

fuse must be added between the power supply and

terminal), the wiring is as Fig.4-8 (Make sure the

PLC and 24V terminal is disconnected)

Fig.4-8 Wiring of external power supply

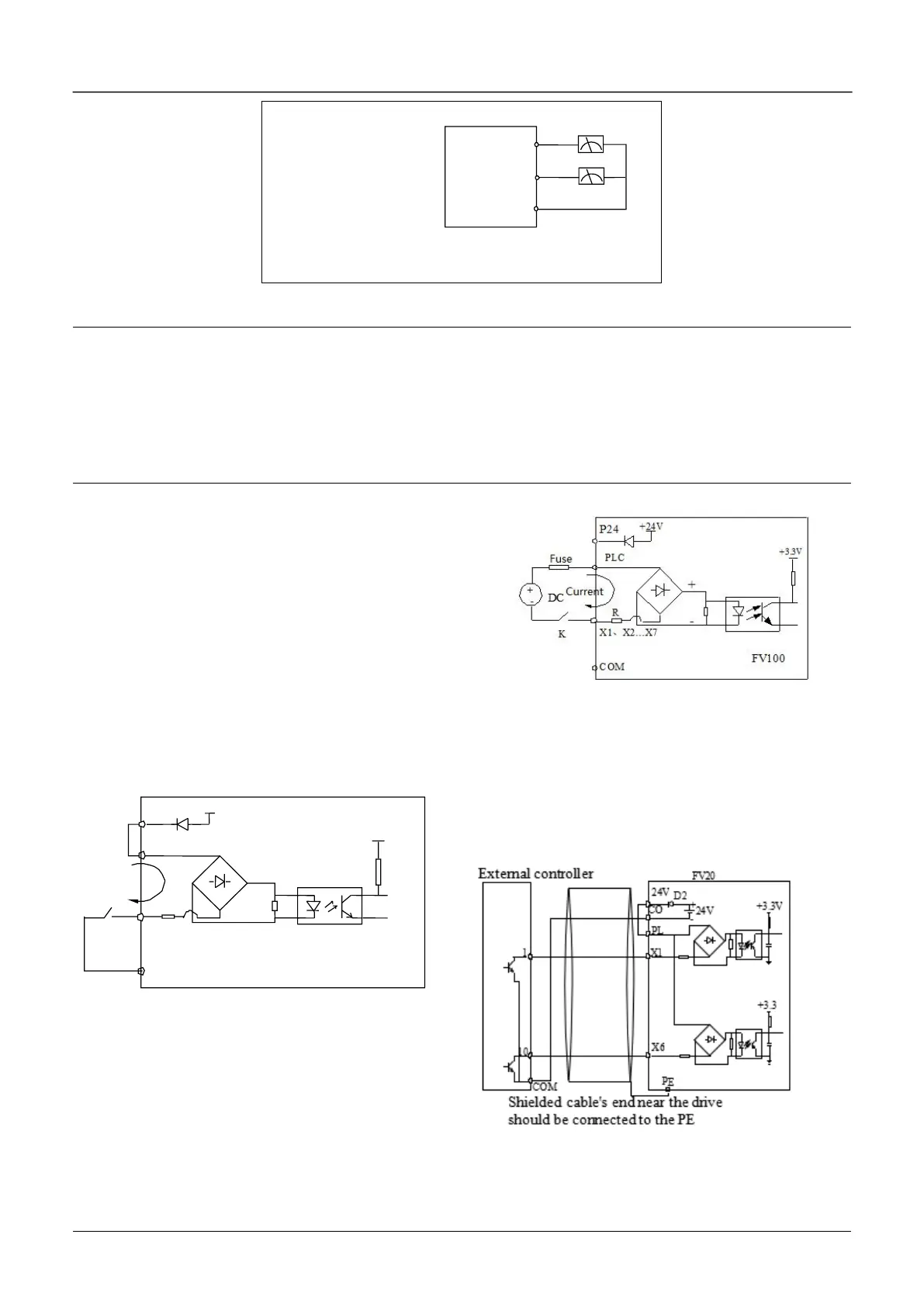

2. Source/drain connection method

1) Use internal +24V power supply of VFD and the

external controller uses NPN transistors whose

common emitter are connected, as shown in the

fig.4-9’’

Fig.4-9 Use internal power supply

for Source connection

Loading...

Loading...