116

Troubleshooting (continued)

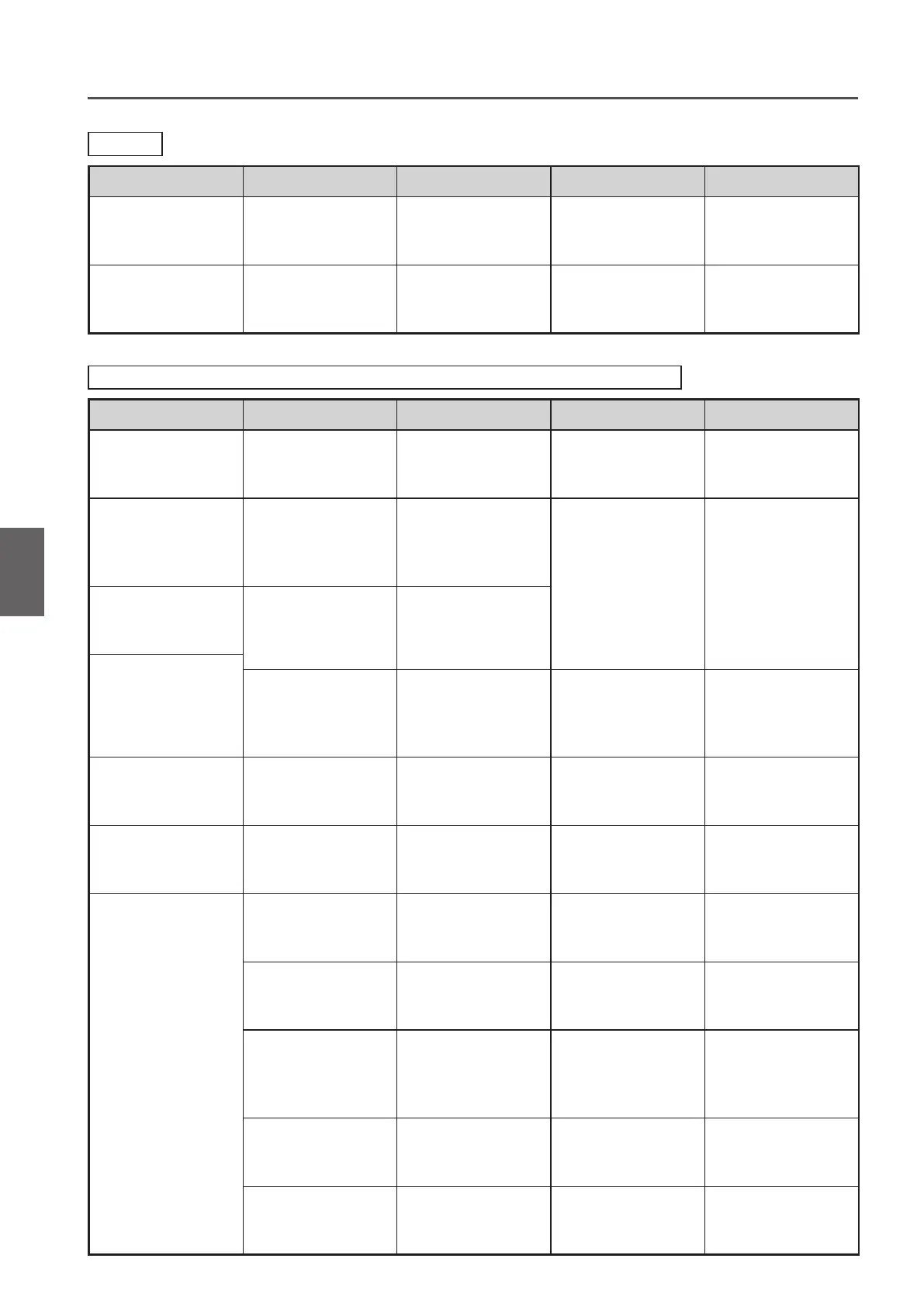

Bearing

Symptom Cause Remedy Main factor Countermeasure

Unable to lift a load. Sticking, Breakage Replace the bearing. Use under hot

environment or

excessively frequent use

Avoid using under

hot environment or

excessively frequent use

Strange noise Deterioration Replace the bearing. Use under hot

environment or

excessively frequent use

Avoid using under

hot environment or

excessively frequent use

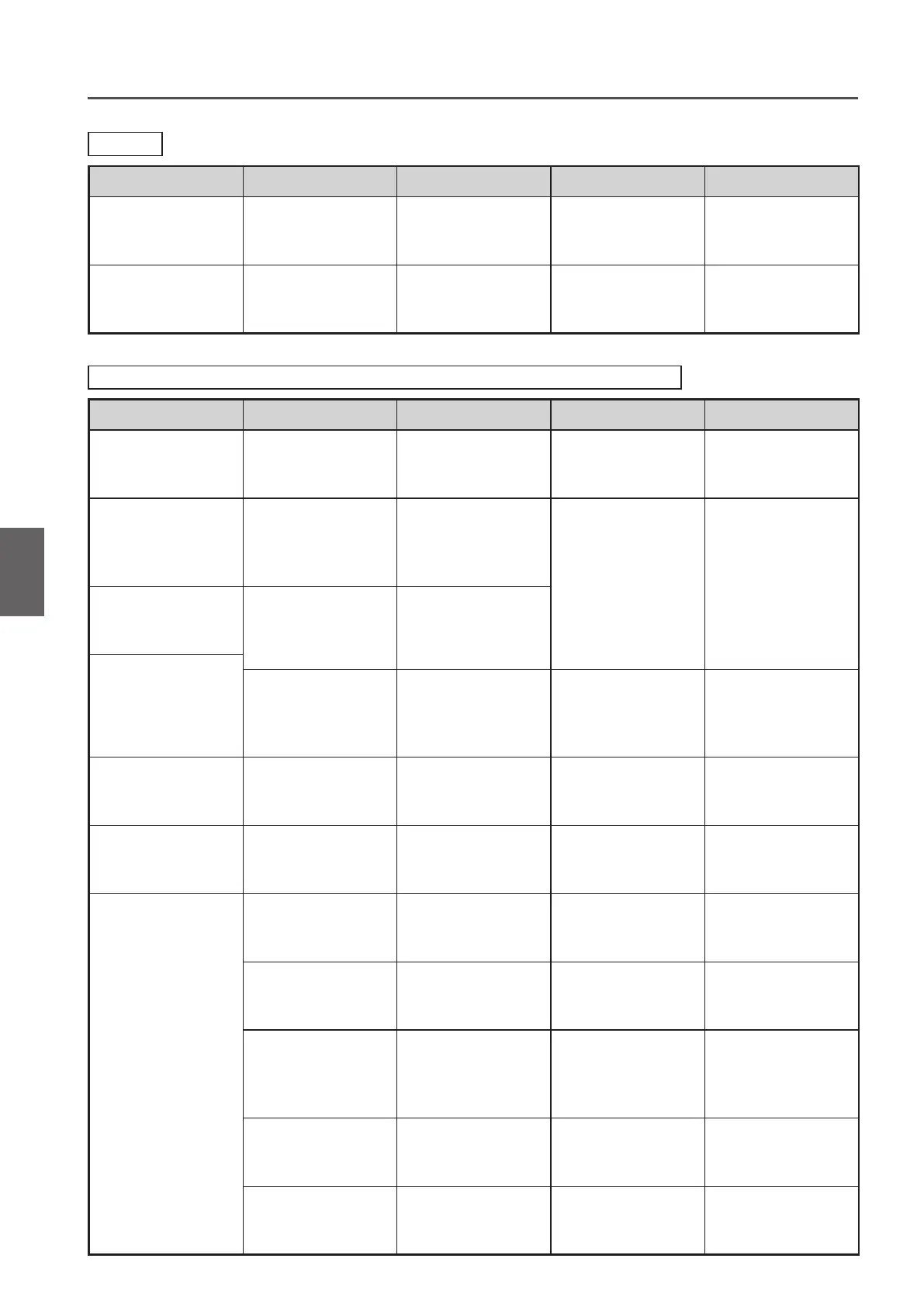

Traveling motion of the Trolley (common for motorized/manual trolley)

Symptom Cause Remedy Main factor Countermeasure

Unable to travel due to

slipping of wheel

Inclination of Travel Rail Make sure that rail

gradient is within 1

degree.

Improper installation of

Travel Rail

Install the Travel Rail

correctly.

Unable to travel due

to slipping of wheel,

or unable to travel in

uniform motion

Oil attachment on

running surface of the rail

Wipe off the attached

foreign matter.

Use under the

environment likely to

attach foreign matter

Clean the Travel Rail

regularly.

Sounds abrasion sound

when running on a

curved rail

Friction resistance

between wheel and rail

Apply small amount of

grease on the rail surface

where noise generates.

Unable to travel on the

curved rail

Interference of the trolley

and the curved rail

Make sure that the rail

curvature is larger than

the minimum turning

radius. (See P43, 48)

Use of the curved rail

of curvature less than

minimum turning radius

Do not use the curved

rail of curvature less than

minimum turning radius

Unable to travel due to

wheel floating

Pulling a load in an

inclined direction (floating

wheel)

—

Operating method Use the electric chain

hoist correctly.

Wheel unable to rotate Defective gear

engagement

Remove the stain and

foreign matter on the

wheel and the gear.

Ambient conditions,

environment

Check regularly.

Meandering

Strange noise

Wrong adjustment of

collar

Check the number

of collars and their

assembled positions

Incomplete checking Assemble correctly.

Uneven abrasion of the

wheel

Check the abrasion of the

wheel

Traveling on curved rail

or unevenness of running

surface

Check regularly.

Deformation of wheel Check the distortion of

wheel and damage of

running surface

Excessively frequent

collision with stopper or

unevenness of running

surface

Replace the wheel

Use the electric chain

hoist correctly.

Deterioration of wheel

bearing

Check if rolling noise

sounds when the wheel

is rotating.

Expiry of service life Replace the wheel

bearing.

Deformation and

abrasion of the rail

Check the abrasion and

deformation of the rail.

Over load or expiry of

service life

Replace the rail.

Use the electric chain

hoist correctly.

Chapter 3 Troubleshooting

3

Bearing / Traveling motion of the Trolley (common for motorized/manual trolley)

Troubleshooting

Loading...

Loading...