78

Chapter 2 Inspection

Periodic Inspection (continued)

Item Check method Criteria When failed

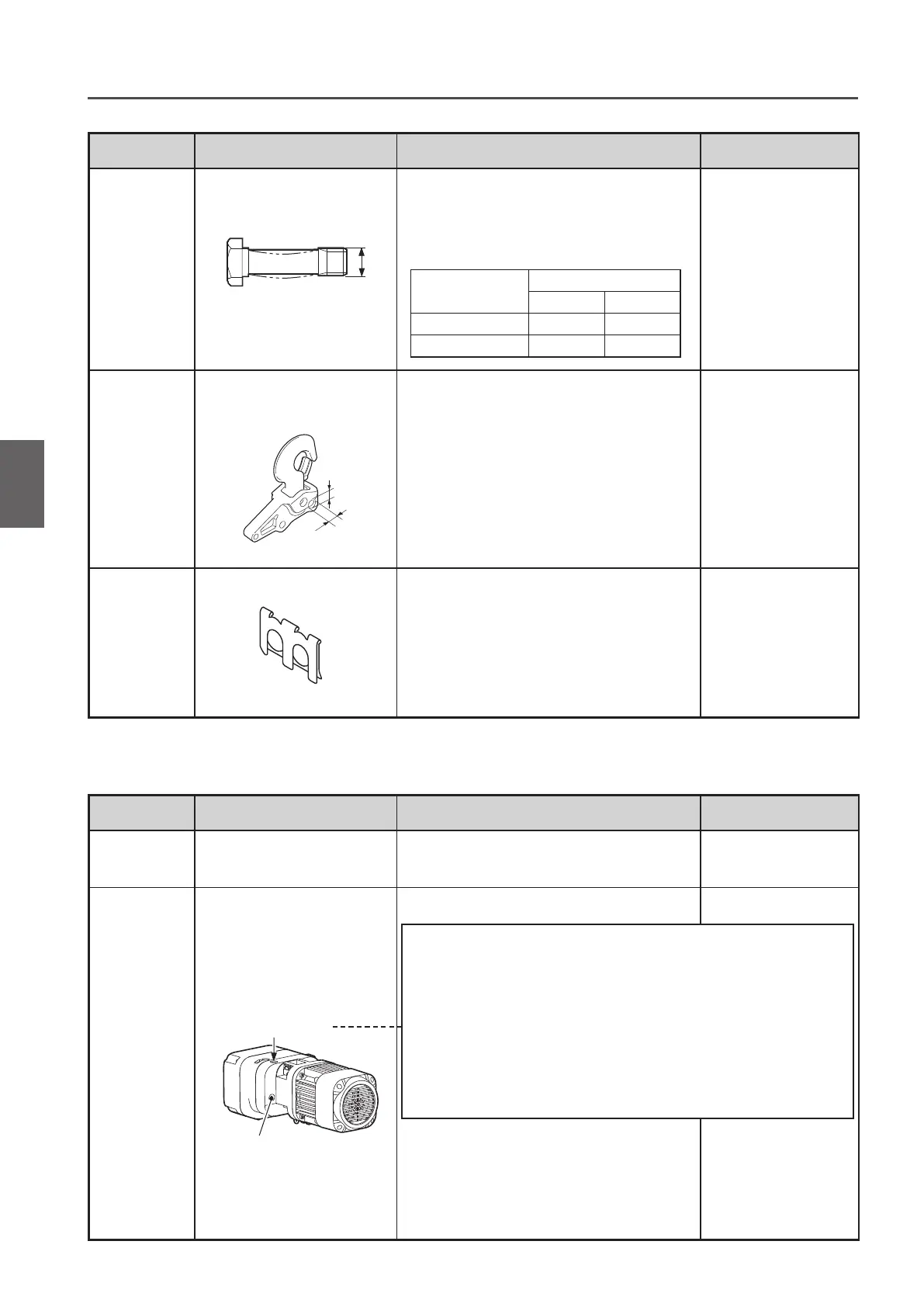

Chain Pin

(double type

only)

• Check visually and measure

with vernier caliper.

d

• Tohavenoapparentdeformationandaw.

Service Limit of Chain Pin

(Do not fall short of the limit value.)

Code

Diameter d (mm)

Standard Limit value

032S/IS 10.8 10.3

050S/IS 12.9 12.3

Replace the Chain Pin.

Connection

Yoke D

(double type

only)

Deformation

of mounting

hole for the

Chain Pin

• Measure the dimensions a

and b with vernier caliper.

b

a

• The difference between dimensions a (vertical)

and b (lateral) must be within 0.5 mm.

• To have no apparent deformation and abrasion

Replace the

Connection Yoke D.

Shaft

Retainer Clip

• Check visually.

Shaft Retainer Clip

• To have no deformation, abrasion and damage

• To be attached securely without loosening

Replace the Shaft

Retainer Clip.

Item Check method Criteria When failed

Oil Leakage • Check visually. • To have no leakage of gear oil from packings,

oil seals or oil plugs.

Replace the Packing

and the Oil Seal.

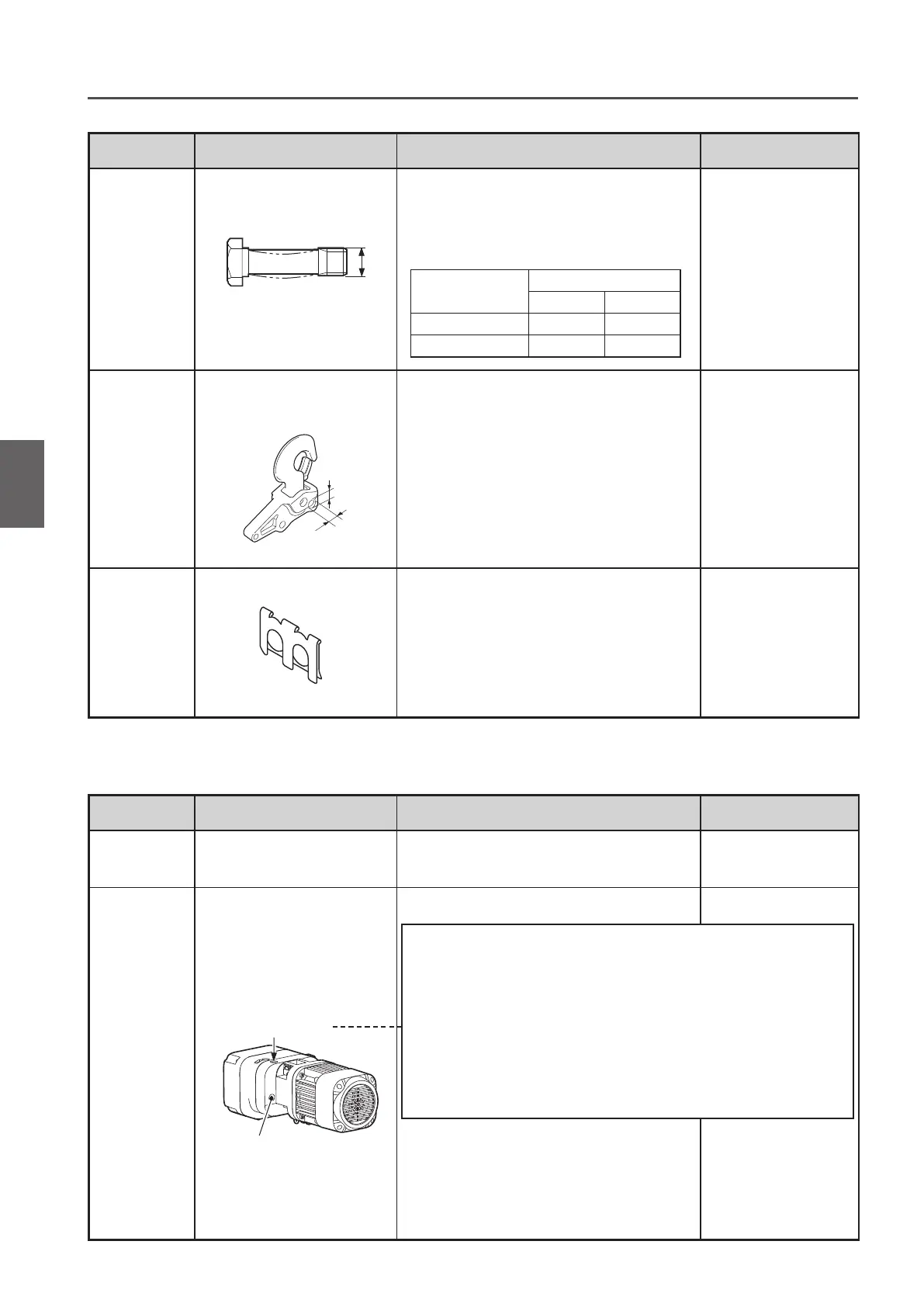

Oil amount

and stain

• Check the oil level from

the oil check hole. (The

position of the oil check hole

depends on the model. See

P40.)

Oil check hole

• Check the operating hours

using the CH Meter.

• Oilislledenoughclosetotheoilcheckhole.

• Gear oil has viscosity but not stained.

• Refer to “Guidelines and Precautions on Gear

OilChangeCycle”forthereplacementofoil.

(P90)

Replace the Oil.

■

Oil

•

Check the oil level through the oil cap at the top (shown by an arrow)

for electric chain hoist equipped with the friction clutch with mechanical

brake. (Do not open the oil check hole at the side. Or, oil leaks out.) When

checking the oil level, insert the check bar into the oil check hole, tilting the

bar slightly, to see the oil level.

•

The distance between the hole and the oil level is 75 mm for the body size

B, 100 mm for the body size C/D, 120 mm for the body size E, and 130

mm for the body size F respectively.

Electric Chain Hoist (ER2) Periodic Inspection Periodic Inspection

2

Loading...

Loading...