133

• When any abnormality is observed during inspection, stop the

use of electric chain hoist, indicate “FAILURE”, and contact the

maintenance engineer or KITO for repair.

Use of the product with abnormality may result in death or serious injury.

Mandatory

Decide the check items

appropriate to the

environment and operating

conditions of the customer.

NOTE

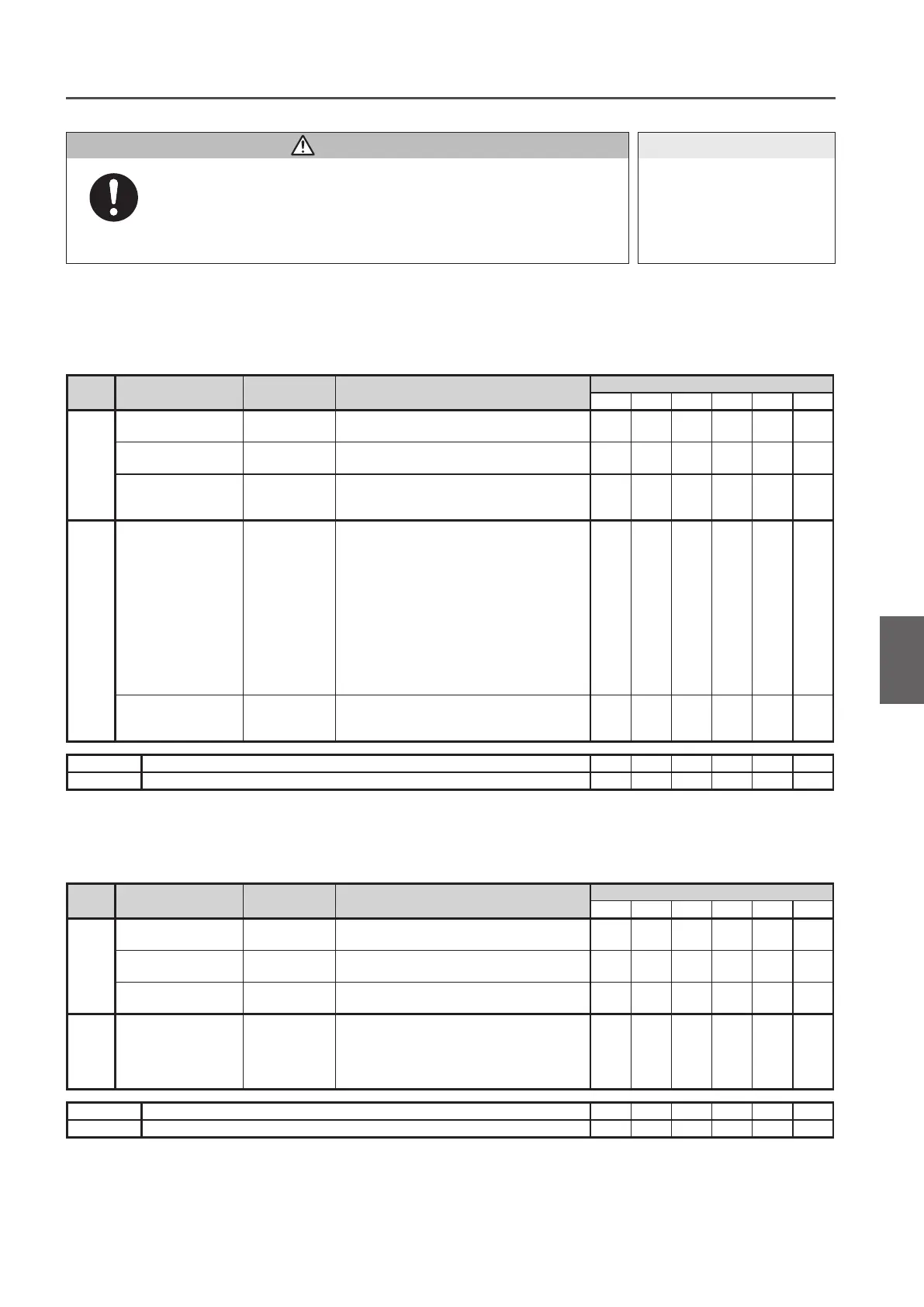

A

Check Sheet for

ER2 Series

Electric Chain Hoist Daily inspection

■

Motorized Trolley MR2 Daily Inspection

■

Check result :

○

Good,

△

To be replaced (adjusted) next inspection,

×

Bad, Needs replacement (adjustment)

Category

Check item

Check

method

Criteria

Inspection date/result

/ / / / / /

Appearance

Indication of nameplates

and labels

Visual inspection To have no peeled off. To be legible clearly.

Deformation and

damage of each part

Visual inspection

To have no apparent deformation and corrosion

Frame to have no apparent deformation

Bolts, nut, split pins

Visual inspection

or inspection with

tools

To have no loosened bolts, nuts, and split pins that

can be seen from exterior. To have no come-off.

Function/performance

Operational check

Traveling

operation with no

load

• To travel smoothly. To have no serpentine motion

and vibration.

• Electric Chain Hoist operates in the same direction

as that of the push button operation

• Motor to stop immediately when stopping the

operation

• All operations to stop when Emergency Stop is

pressed

• Electric Chain Hoist not to operate when pressing

the push button while Emergency Stop is pressed

• Electric Chain Hoist to operate normally when

canceling Emergency Stop

Brake

Traveling

operation with no

load

When stopping the operation, brake to operate

securely and motor to stop immediately.

Executed by Inspector

Checked by Maintenance Engineer

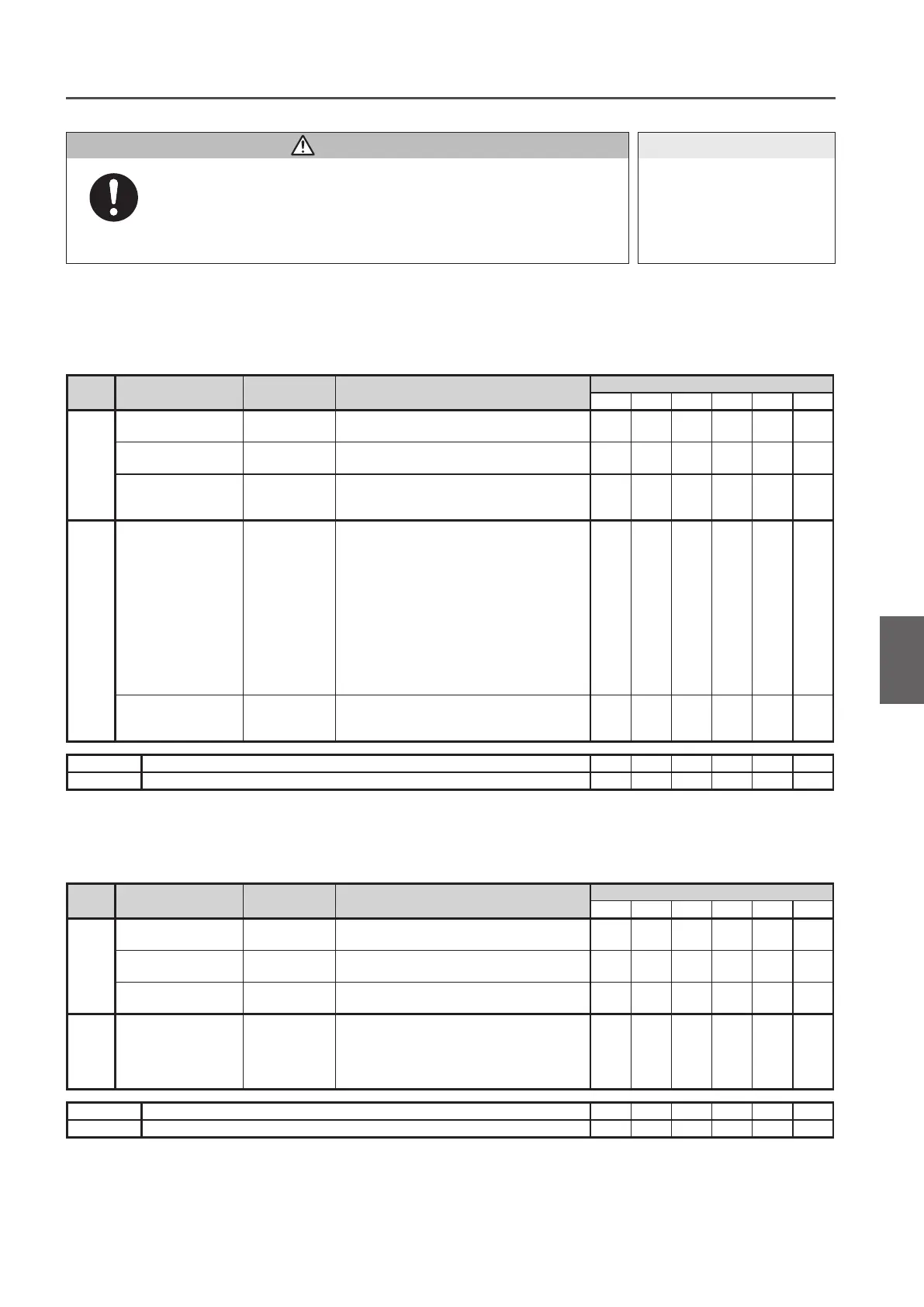

■

Manual Trolley TS2 (TSG/TSP) Daily Inspection

■

Check result :

○

Good,

△

To be replaced (adjusted) next inspection,

×

Bad, Needs replacement (adjustment)

Category

Check item

Check

method

Criteria

Inspection date/result

/ / / / / /

Appearance

Indication of nameplates

and labels

Visual inspection To have no peeled off. To be legible clearly.

Deformation and

damage of each part

Visual inspection

• To have no apparent deformation and corrosion

• Frame to have no apparent deformation

Bolts, nut, split pins Visual inspection

To have no loosened bolts, nuts, and split pins that

can be seen from exterior. To have no come-off.

Function/

performance

Operational check

Traveling

operation with no

load

• To travel smoothly. To have no serpentine motion

and vibration.

Executed by Inspector

Checked by Maintenance Engineer

DANGER

Loading...

Loading...