135

A

Check Sheet for

ER2 Series

Electric Chain Hoist Frequent Inspection

■

Motorized Trolley MR2 Frequent Inspection

■

Check result :

○

Good,

△

To be replaced (adjusted) next inspection,

×

Bad, Needs replacement (adjustment)

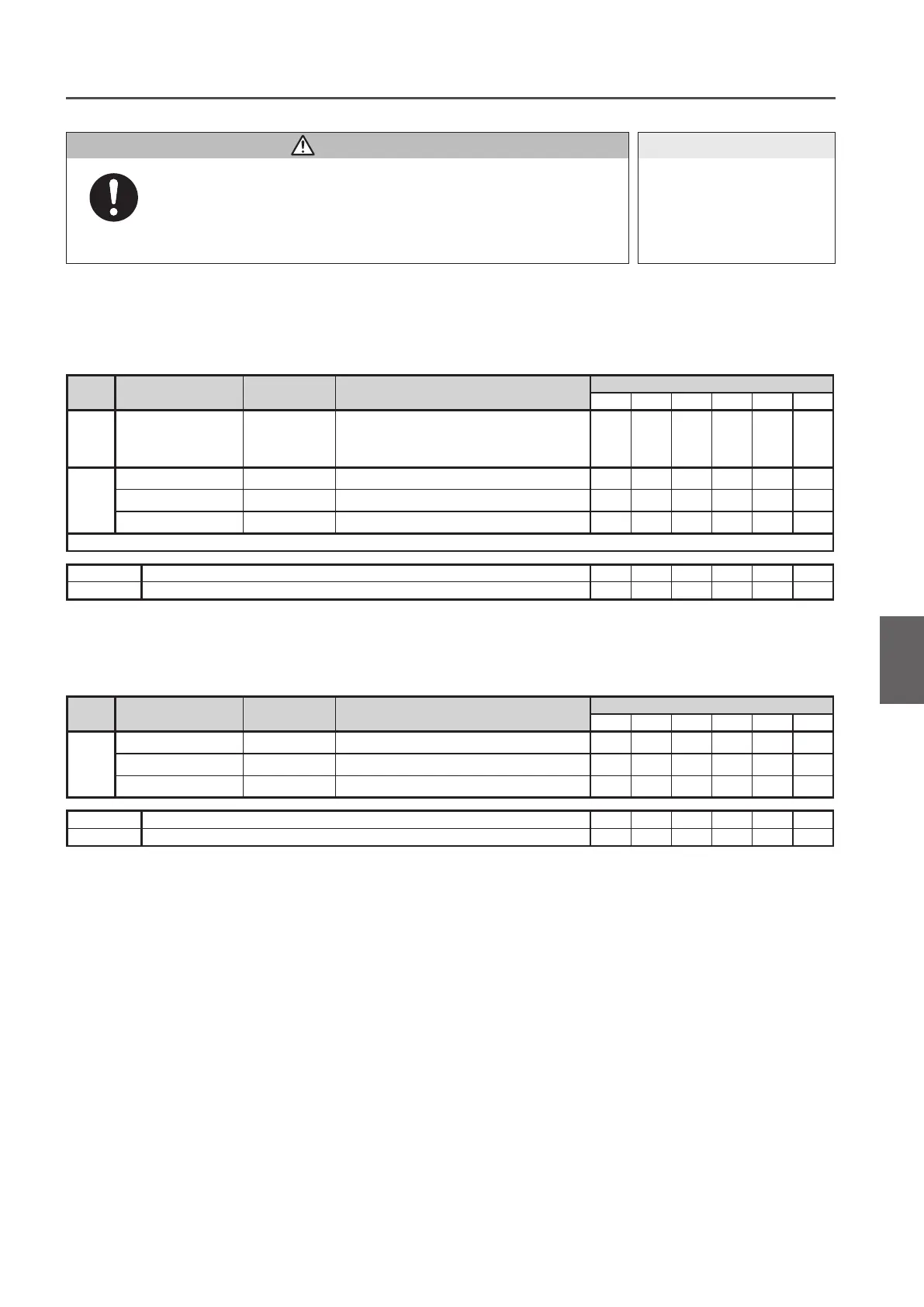

Category

Check item

Check

method

Criteria

Inspection date/result

/ / / / / /

Preceding

inspection

Daily inspection

Check the

execution

When performing frequent inspection, also perform

the daily inspection.

Appearance

Combination Shake the hoist Electric chain hoist to swing right and left swiftly

Travel rail (guider) Visual inspection To have apparent deformation and damage

Oiling Visual inspection To be oiled adequately

Refer to check table of electric chain hoist ER2 for electrical parts, push button switch, power feeding and electrical characteristics.

Executed by Inspector

Checked by Maintenance Engineer

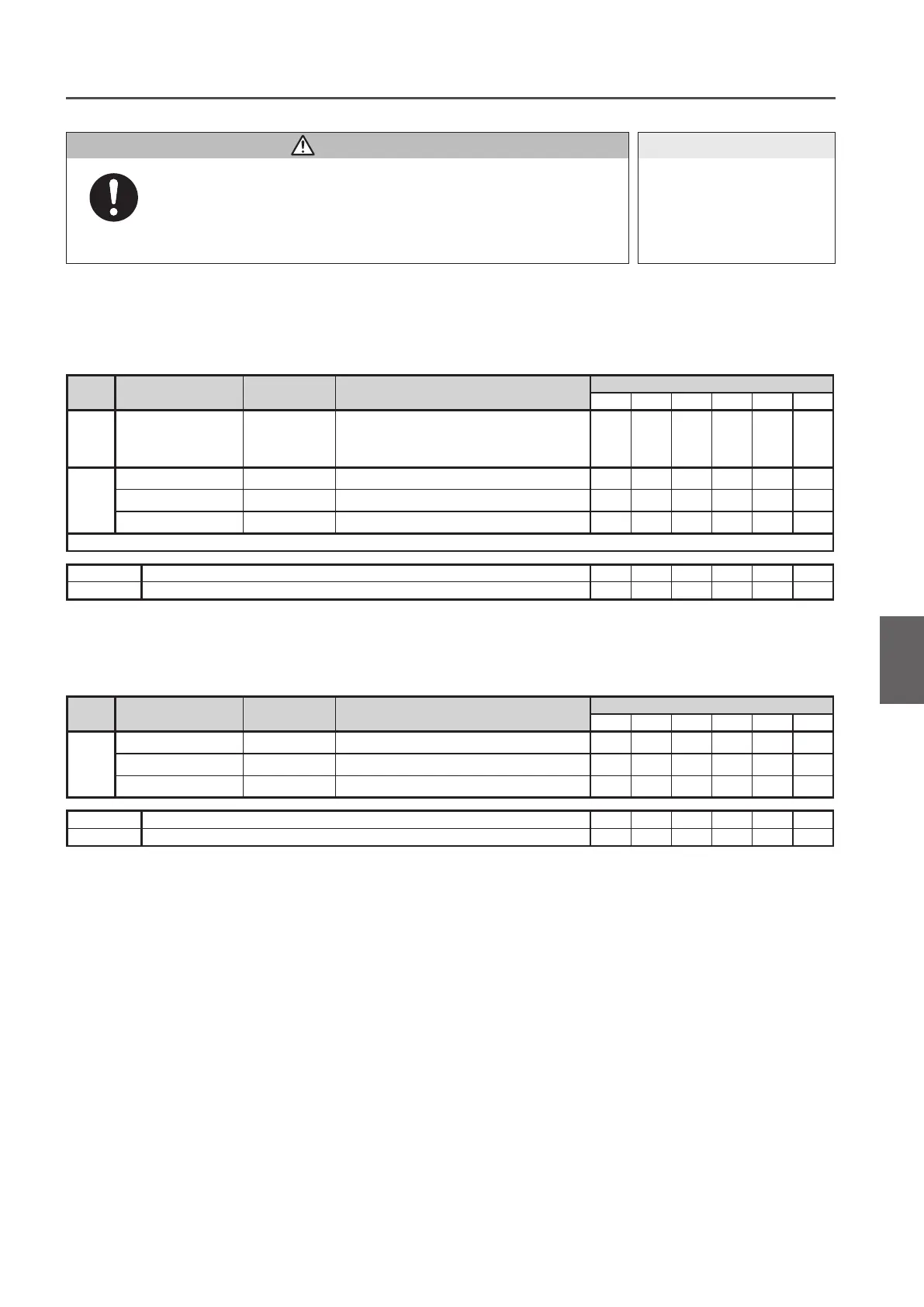

■

Manual Trolley TS2 (TSG/TSP) Frequent Inspection

■

Check result :

○

Good,

△

To be replaced (adjusted) next inspection,

×

Bad, Needs replacement (adjustment)

Category

Check item Check method Criteria

Inspection date/result

/ / / / / /

Appearance

Combination Shake the hoist Electric chain hoist to swing right and left swiftly

Travel rail (guider) Visual inspection To have apparent deformation and damage

Oiling Visual inspection To be oiled adequately

Executed by Inspector

Checked by Maintenance Engineer

• When any abnormality is observed during inspection, stop the

use of electric chain hoist, indicate “FAILURE”, and contact the

maintenance engineer or KITO for repair.

Use of the product with abnormality may result in death or serious injury.

DANGER

Mandatory

Decide the check items

appropriate to the

environment and operating

conditions of the customer.

NOTE

Loading...

Loading...