60

Chapter 1 Handling the Product

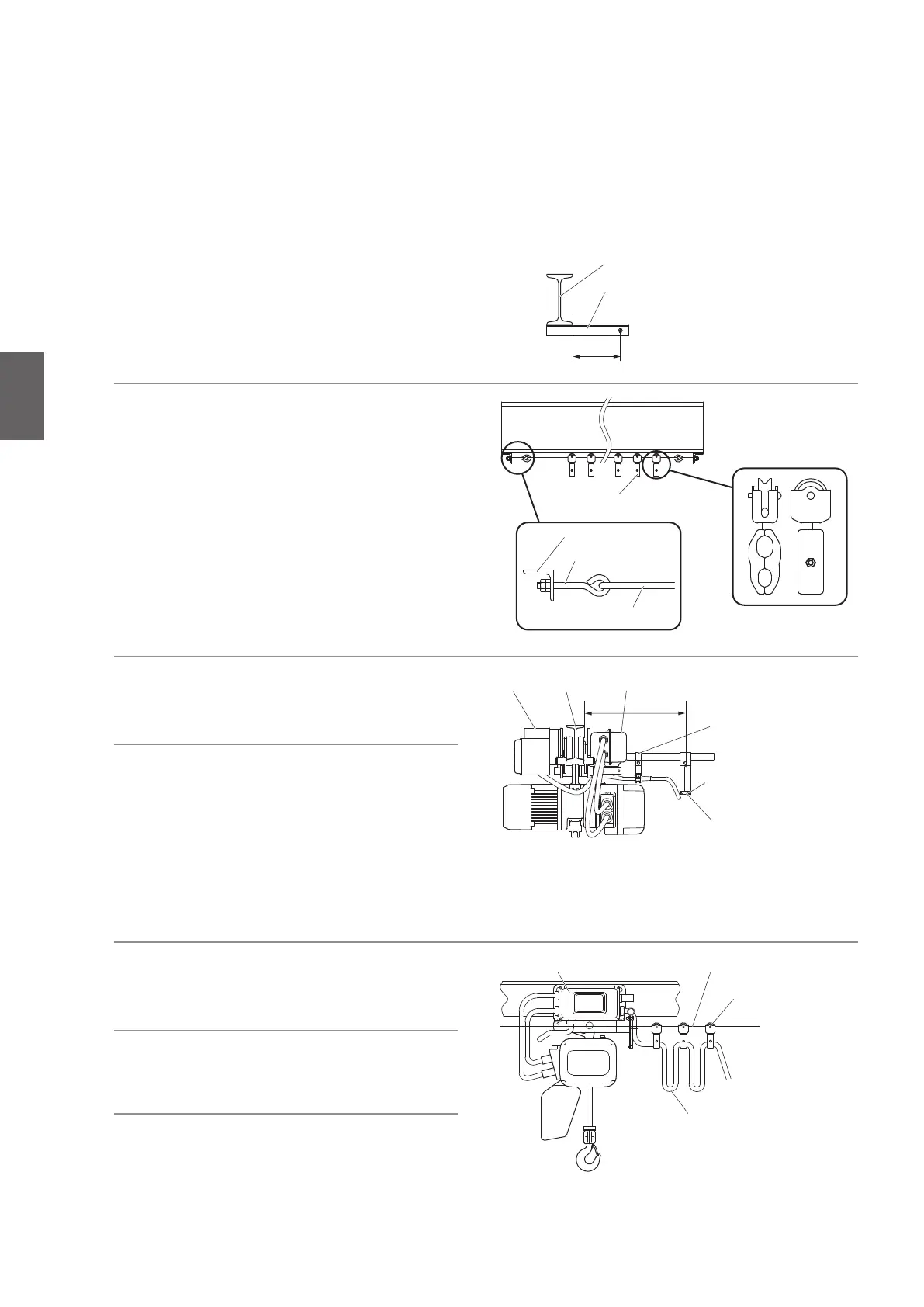

Messenger WireConnection Box

Cable hanger

Power Cable

Wire Guide

Pan head screw

Messenger Wire

Wire support bar

Rail

Wire support bar

Beam

Connection Box

Cable support arm

Motor

A

A

Cable Hanger

Wire bolt

■

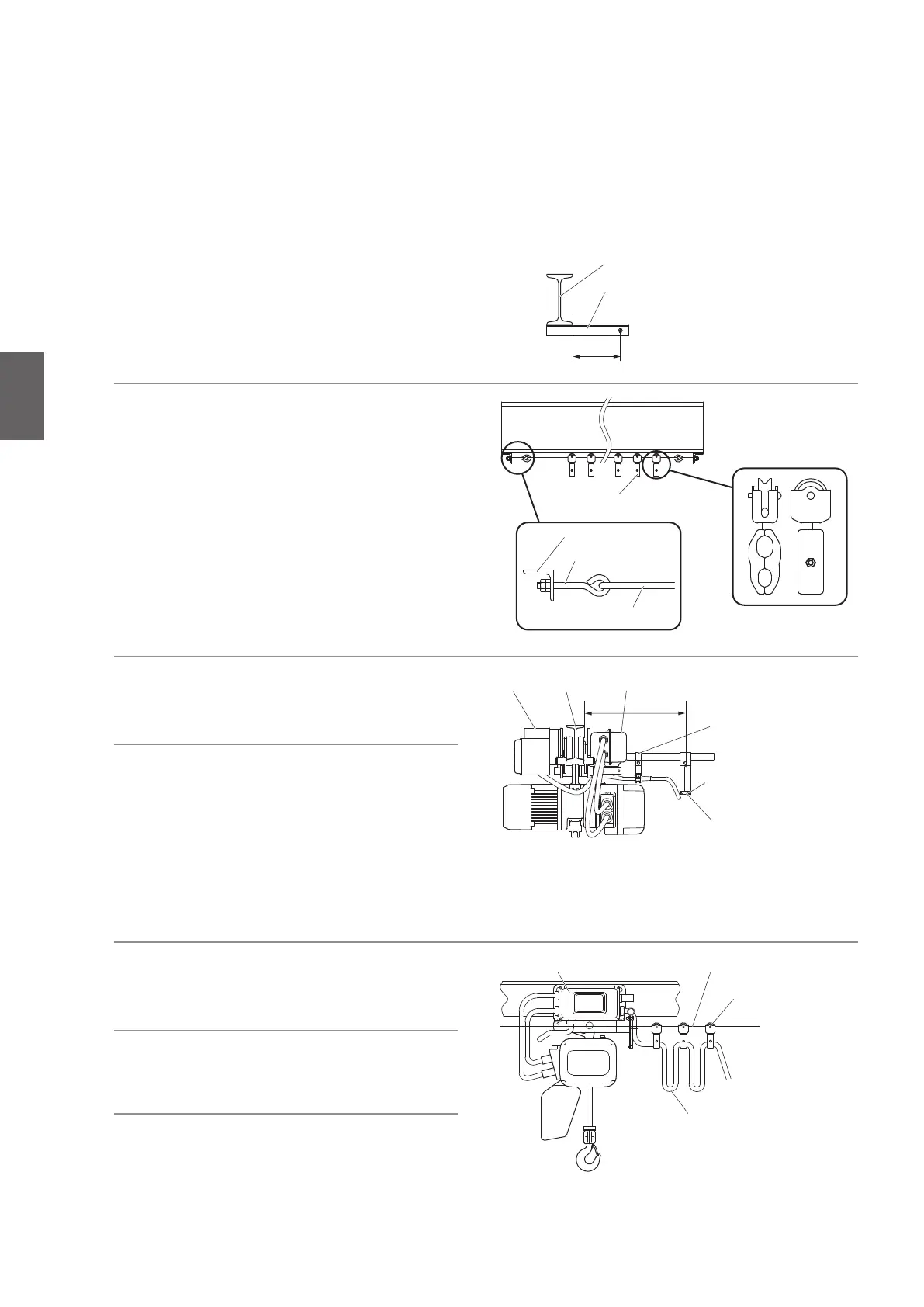

Power Cable Layout for Motorized/Manual trolley type

• In the standard specification the Suspender is provided. T-shape Suspender and angle type Suspender are also

available as optional parts. T-shape Suspender can be applicable to curved rail, however, the application method

differs depending on the condition such as radius of curvature. In such case, contact KITO.

2) Tie the Messenger Wire passed through

the Cable Hanger to the Wire Support

Bar with two Wire Bolts.

•

The recommended mounting interval of the

Cable Hangers is 1.5 m to 2 m.

•

Use steel wire of 3 to 6 mm in diameter for the

Messenger Wire.

1) Mount the wire support bar at the both

ends of the rail.

3) Loosen two pan head screws and

remove the end clip of the wire guide.

4) Pass the Messenger Wire through the

groove of the messenger guide. Mount

the end clip with two pan head screws.

•

The dimension A between the side face of

the rail and the groove of the wire guide must

be same as that of mounting hole of the Wire

support bar for the Messenger Wire and the

side face of the rail.

5) Fix the Power Cable to the Cable Hanger.

6) Mount the Cable Support to the Cable

Support Arm.

7) Insert the Power Cable into the

Connection Box of MR2 and connect it

to the terminal panel.

• Connect wires correctly according to the wiring

diagram affixed on the Connection Box.

1

InstallationInstalling the Trolley Combined Model

Loading...

Loading...