86

Periodic Inspection (continued)

Chapter 2 Inspection

Item Check method Criteria When failed

Rail Surface • Check visually. • To have no attachment of paint, oil and foreign

matter.

• To have no dust and powder due to abrasion

Clean the Travel Rail.

Deformation

and Abrasion

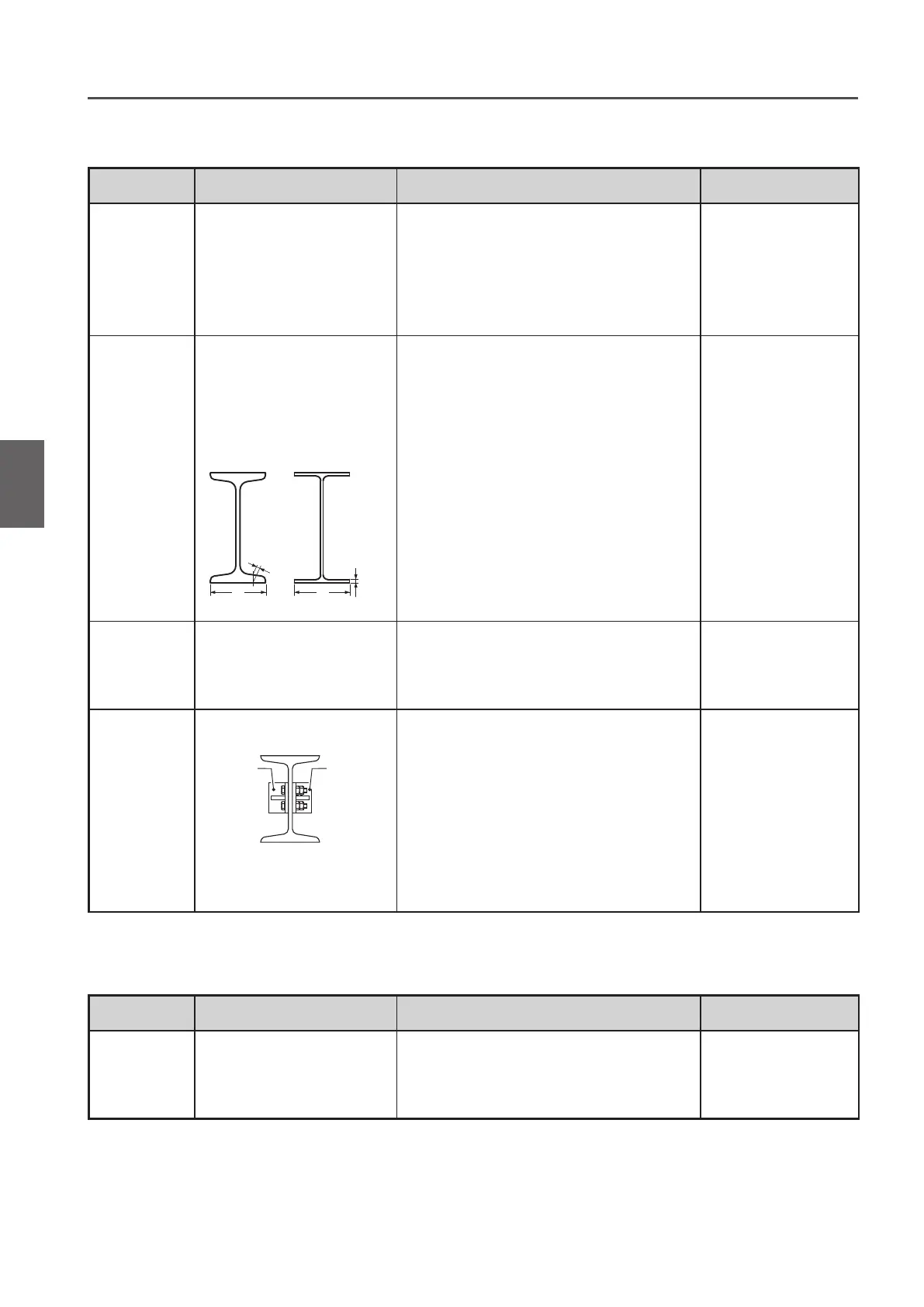

• Check the deformation

and abrasion visually and

measure them with vernier

caliper.

I-beam H-beam

B B

t

t

• Tohavenodeformationofbeamangesuch

as twist and shear drop

• To have no exceeding abrasion of rail surface

• Service limit of B: up to 95 % of the dimension

at purchasing

• Service limit of t: up to 90 % of the dimension

at purchasing

Replace or repair the

Travel Rail.

Rail Mounting

Bolt

• Check visually. • To have no loosened bolt or fall-off Tighten the bolts

securely.

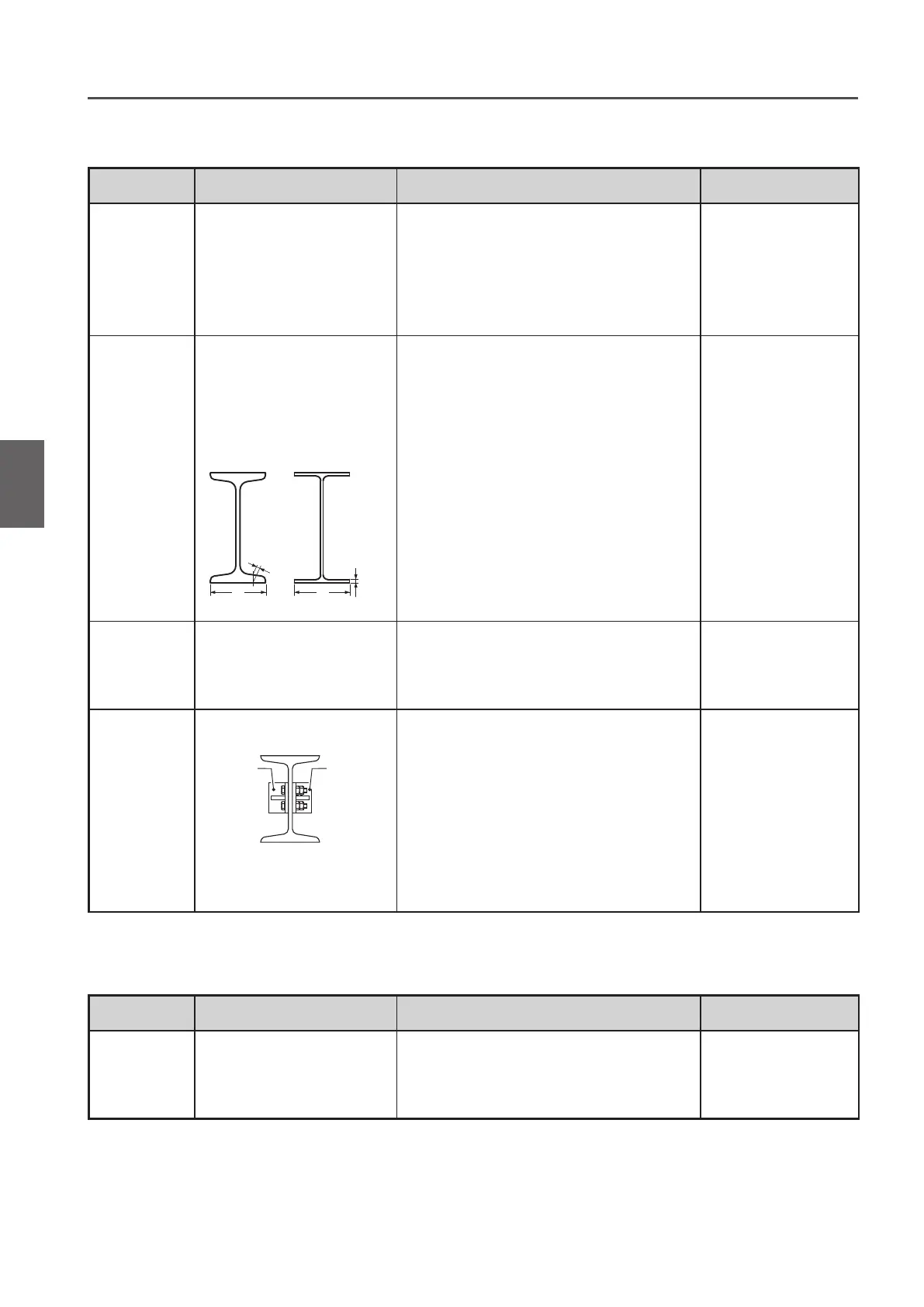

Stopper

• Check visually.

Stopper Stopper

• The stoppers must be mounted at the both

ends of the Travel Rail securely.

Tighten the Stoppers.

■

Travel Rail

Item Check method Criteria When failed

Appearance • Check the cable surface

visually.

• The Relay Cable has no deformation or

damage. To be mounted securely.

Replace the Relay

Cable.

■

Relay Cable

■

Electrical Equipment and Electric Characteristics

Refer to Electric Chain Hoist (ER2) Periodic Inspection (P82).

Motorized Trolley (MR2) Periodic Inspection Periodic Inspection

2

Loading...

Loading...