89

Item Check method Criteria When failed

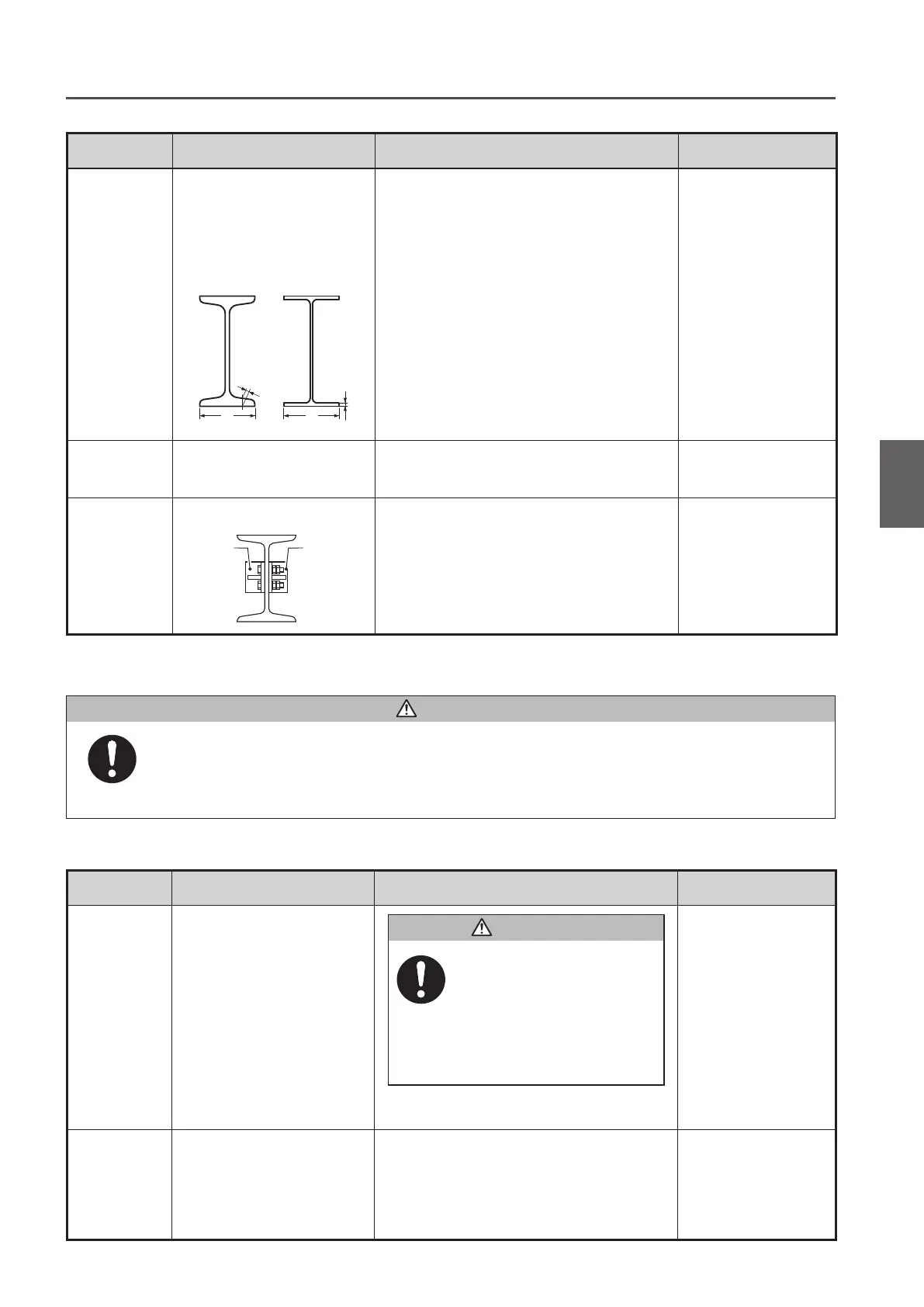

Deformation

and Abrasion

• Check the deformation

and abrasion visually and

measure them with vernier

caliper.

I-beam H-beam

B B

t

t

• Tohavenodeformationofbeamangesuch

as twist and shear drop

• To have no exceeding abrasion of rail surface

• Service limit of B: up to 95 % of the dimension

at purchasing

• Service limit of c: up to 90 % of the dimension

at purchasing

Replace or repair the

Travel Rail.

Rail Mounting

Bolt

• Check visually. • To have no loosened bolt or fall-off Tighten the bolts

securely.

Stopper

• Check visually.

Stopper Stopper

• The stoppers must be mounted at the both

ends of the Travel Rail securely.

Tighten the Stoppers.

Item Check method Criteria When failed

Operational

Check

• Perform the daily inspection

items with capacity. (Refer

to Daily inspection Items.

(P24))

• Be sure to perform

the capacity test after

completion of the no-load

test.

Performing the capacity test without

prior no-load test may result in death

or serious injury.

Mandatory

DANGER

Disassemble the

electric chain hoist

to check whether it is

assembled correctly

and has no abnormal

part.

• Referto“DailyInspectionItems”.(P24)

Abnormal

Noise

• To make the electric chain

hoist travel with a capacity

• To have no irrotating sound

Disassemble the electric

chain hoist to check whether

it is assembled correctly and

has no abnormal part.

■

Function and Performance

● Perform the following inspections with capacity.

Periodic Inspection

2

Manual Trolley (TSG/TSP) Periodic Inspection

• After completion of the inspection of each part, perform the operational check for correct operation.

Neglecting to perform the operational check may result in death or serious injury.

Mandatory

DANGER

Loading...

Loading...