91

■

Guidelines on the service life of contactor and its replacement

Replace the Contactor in accordance with the following rate of inching and the number of start. Replace the

Contactor every five years even if the number of start does not reach at the following.

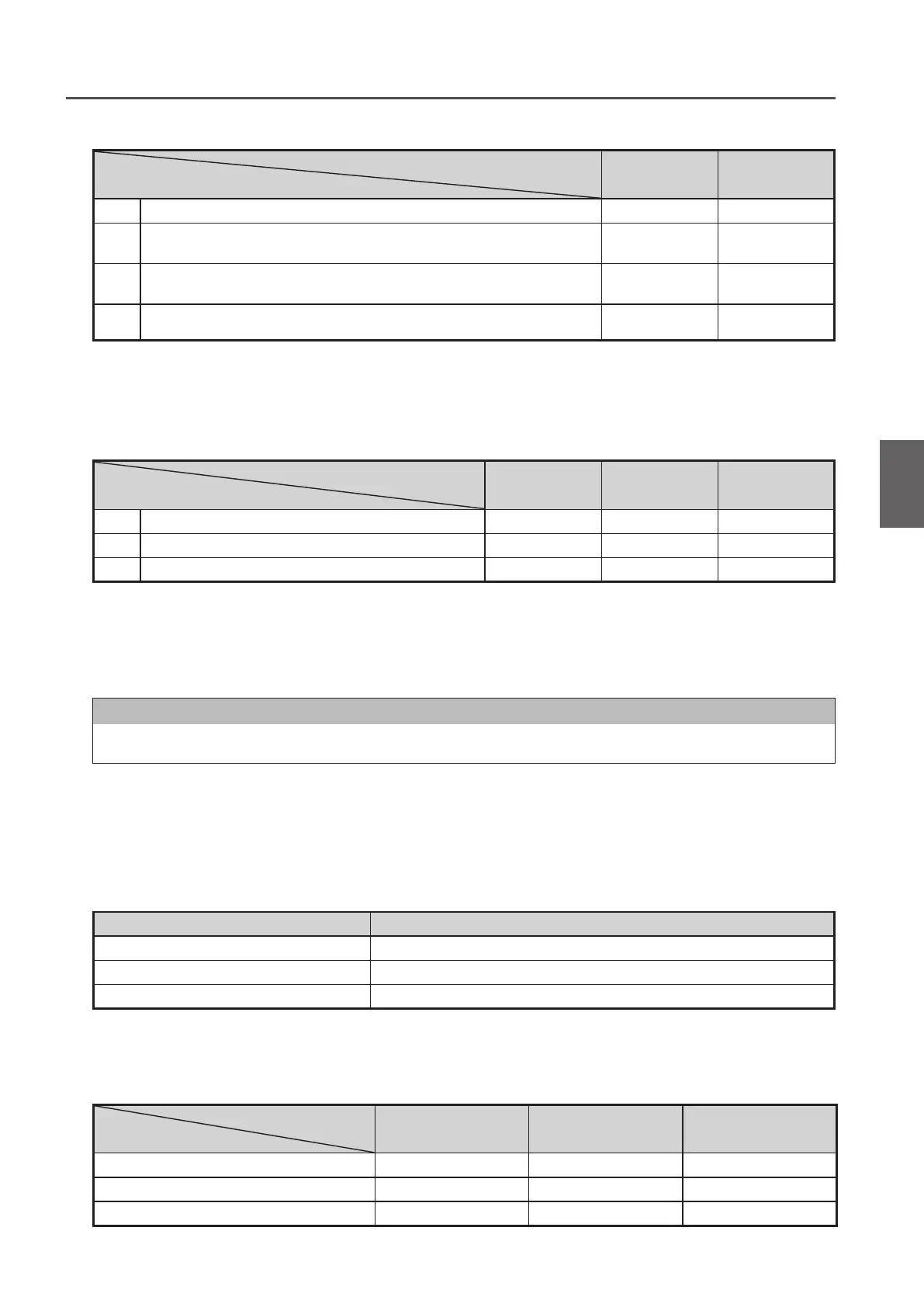

Number of start to replace contactor

Rate of inching

Every 200,000

times

Every 500,000

times

Every 1 million

times

Low Normally operating with scarce inching

○

Medium

Normally operating with occasional inching

○

High Normally operating with inching at a half times or more

○

NOTE) · For single speed model, check the number of start with the CH Meter. (Refer to “Check of Operating Hours and Start Times (CH

Meter)”.(P92))

· For dual speed VFD model, check the number of start and operating hours with the indicator of the VFD by the maintenance engineer

inaccordancewiththeseparate“VFDManual”.

NOTE

Be sure to use the designated contactor.

■

Guidelines on Brake Inspection

When the number of start reaches at one million times, inspect the brake gap and carry out the following treatment

depending on the condition of the brake gap.

When the number of start reaches at two million times, replace the brake unit as a whole irrespective of the condition

of the brake gap.

Condition of brake gap Treatment

Brake gap reaches at the limit gap. Replace the brake as a whole.

Brake gap reaches at 50 to 100 % of the limit gap. Check the Brake at every 100,000 times until the brake gap reaches at the limit gap.

Brake gap is less than 50 % of the limit gap. Check the Brake at every 200,000 times.

■

Guidelines on Gear Parts Replacement (Load Gear, Gear B,

Pinion, Friction Clutch, Friction Clutch with Mechanical Brake)

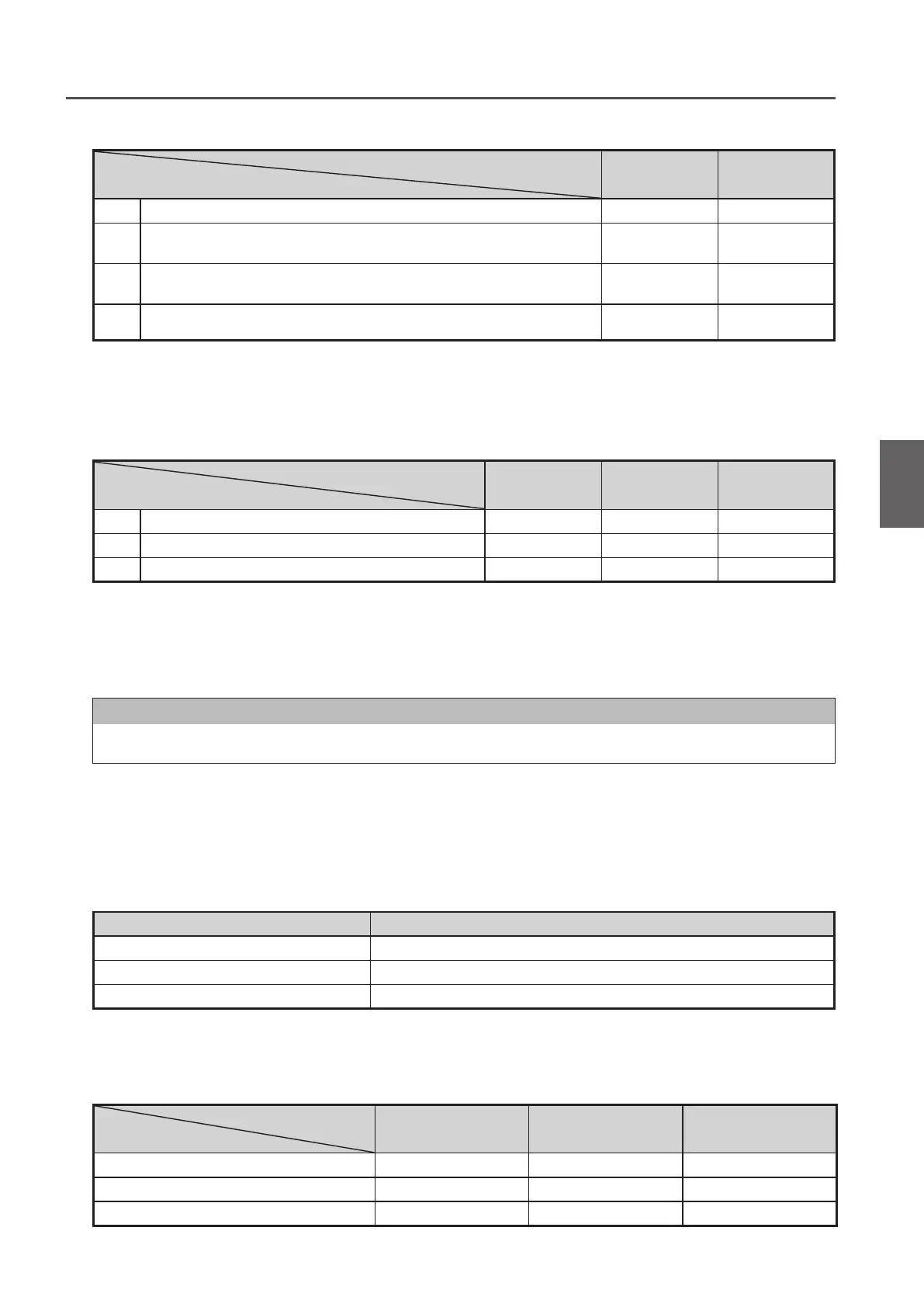

Operating hours to replace parts

Body size grade

Every 800 hours Every 1600 hours Every 3200 hours

M6, 3m – – Parts replacement

M5, 2m – Parts replacement –

M4, 1Am Parts replacement – –

Guidelines for Parts Replacement based on Indication of CH Meter

2

(to be continued)

Operating hour for gear oil change

Rate of loading

Every 200 hrs Every 400 hrs

Light A case where the capacity is rarely applied. Usually the hoist is used with a light load.

○

Medium

A case where the capacity is applied considerably frequently. Usually the hoist is used

with a medium load.

○

Heavy

A case where the capacity is applied considerably frequently. Usually the hoist is used

with a heavy load.

○

Ultra

heavy

A case where the capacity is applied constantly.

○

■

Guidelines on Needle Bearing (for Idle Sheave) Grease Change Cycle

Loading...

Loading...