108

EVO-S, EVO-H MODULAR AIR HANDLING UNITS

OPERATION AND MAINTENANCE MANUAL

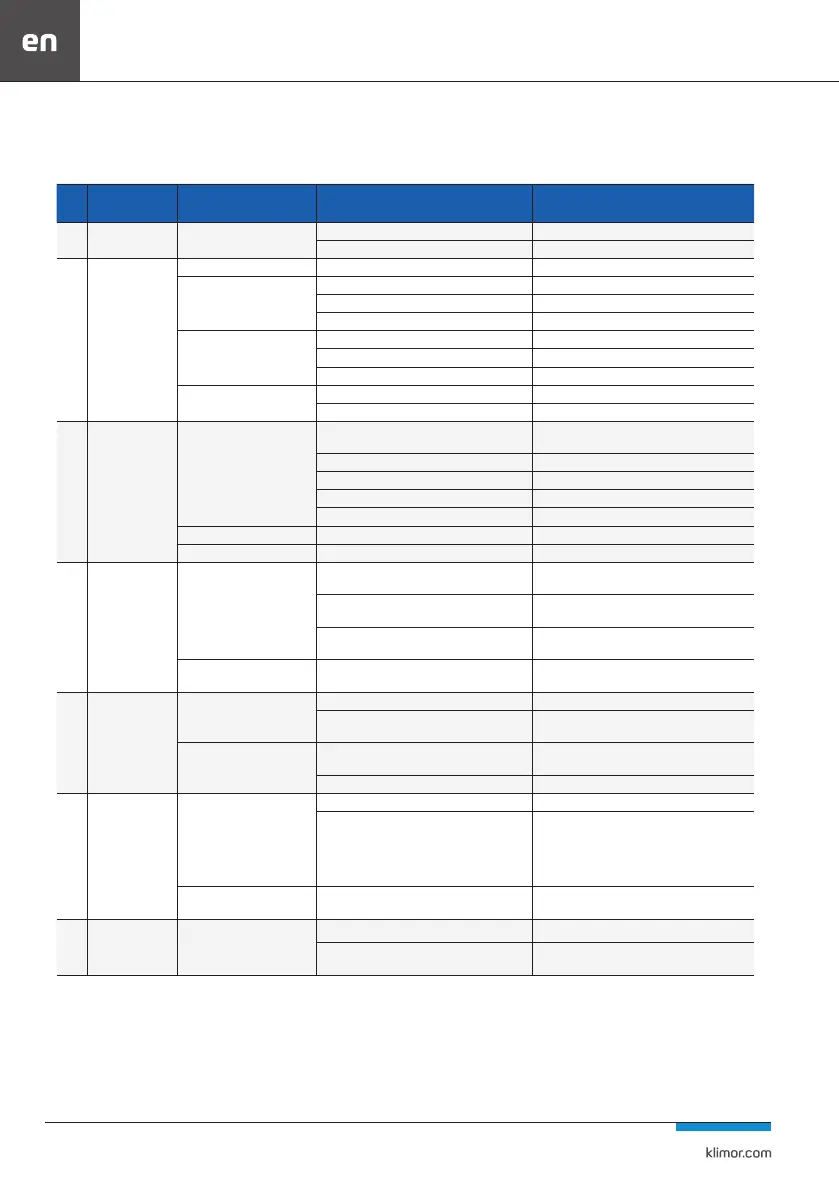

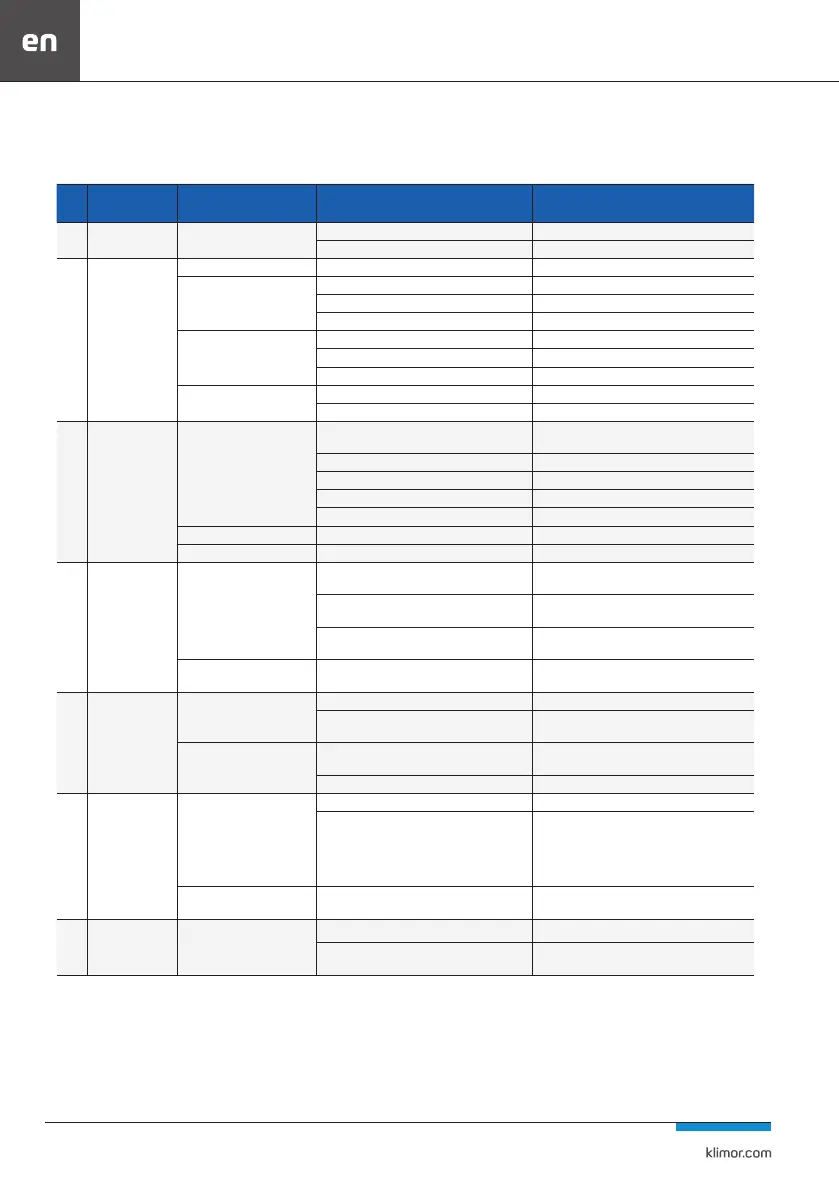

8. List of most common faults

Table 30 List of most common faults in the units

Item Unit

Signs of malfunctioning of

the unit

Cause Removal

1.

Filtering and mixing

section

insucient airow

excessive pollution of the pre-lter or ne lter cleaning or replacement

housing leakage tighten clamps on the covers

2. Fan section

insucient airow damage to the exible fan stub apply a patch by sticking or replace with a new one

airow stop

motor damage removal of damage or replacement with a new one

no power supply to the motor damage repair on the dashboard or on the power cord

closing of the air damper repair of the damage

increased noise

damage to the fan or motor bearing replacement

mechanical damage to the rotor damage repair or replacement

loosening of screw connections tightening nuts and bolts

increased vibrations

damage to dampers replacement

loose rotor at the shaft x the failure or replace with a new one

3. DX cooling section

air temperature at the unit's outlet

too high

wrongly adjusted thermostatic valve (too little cooling

medium is supplied to the cooler)

perform appropriate adjustment

dirty lter on the DX cooler power supply clean the lter insert or replace it with a new one

defective thermostatic valve or control valve replace the valve with a new one

air cooler oiling remove oil from the cooler by reducing overheating

airlocked cooler intake water temperature too low vent the cooler, check the cause of low water temperature

frosting the cooler medium evaporation temperature too low increase the temperature of medium evaporation

Freon leakage leaks on screwed or welded joints locate the leakage point and seal it

4. Cooling section

outlet air temperature too high

not enough water is fed to the cooler

change the setting of the thermostat valve regulator to the

correct one

water supply pressure too low for the cooler

check the position of the fully open shut-o valves on

the supply line

airlocked cooler

check the position of the fully open shut-o valves on the

outlet line vent the cooler,

air temperature at the unit's outlet

too low

Too much water is fed to the cooler change valve regulator thermostat to the correct setting

5. Heating section

Too low air temperature at

the outlet

Not enough water delivered to the heater adjust the thermostatic valve setting

Too low pressure of water delivered to the heater

check position of the fully open cut-o valves at the

supply pipe

Too high air temperature at the

AHU outlet

Air in the heater (water heater)

check position of the fully open cut-o valves at the outlet

pipe and bleed the heater

Too much water delivered to the heater ajust the thermostatic valve setting

6.

Humidication

section

air humidity at the unit's outlet

too low

too little steam or water supply through the humidier check the patency of the nozzles and clean them

water supply pressure too low

check the operation of the electromagnetic valve or check

the operation of the control valve; reduce pressure on

the reduction valve check the reason for water supply

pressure being too low

check the operation of electric steam generator

outlet air temperature too high too much steam or water supply through the humidier

reduce water supply pressure

check the operation of electric steam generator

7.

Damping and

separation section

no possibility to control the

temperature and humidity of the

air leaving the air handling unit

thermometer damage replace with a new one

malfunction of the hygrostat

perform the adjustment according to the instructions or

replace with a new one

NOTE:

ALL WORKS RELATED TO REPAIR AND ADJUSTMENT OF THE AIR HANDLING UNIT POWER SUPPLY SYSTEMS SHOULD

BE PERFORMED IN ACCORDANCE WITH THE OPERATING MANUAL OF THE ENTIRE AIR CONDITIONING SYSTEM.

Loading...

Loading...