95

4.11 RR rotary exchanger

In RR sets, heat recovery takes place in a rotary regenera-

tor, with a recovery eciency of up to 85%. Outlet warm air

ows through the rotor section and heats it up. The rotor

transfers heat from the heated part to the cold air in the in-

take part. For summer conditions it is also possible to reco-

ver cold and humidity.

Rotary exchangers can be used in cases where a slight

mixing of the outlet and intake air is possible. The internal

tightness is dened above 97% when the rotor is installed

on the suction side of the fans.

The rotary heat exchangesr includes a rotary wheel and a

drive mechanism. A purge sector is mounted on the rotor’s

supporting construction, which prevents excessive leakage

of the exhaust air.

The section casing has an inspection cover allowing access

to the drive mechanism and the rotor.

Depending on the size of the unit, the rotor set can be built

into the unit or be a separate section.

The rotor is made up of layers of aluminium foil winded on

the axis of rotation, alternately smooth and corrugated,

forming channels for airow. To recover the latent heat re-

sulting from the humidity dierence, the foil is additionally

covered with a layer of hygroscopic material.

The drive mechanism consists of a belt transmission, elec-

tric motor (OJ-MRHX) and motor base that automatically

adjusts the belt tension.

The motor is supplied with an OJ-DRHX controller and both

units are connected by a factory-supplied wire.

OJ-DRHX is equipped with advanced software to monitor

the rotation of the rotary exchanger, which means that no

additional control is required to break the drive belt in the

form of an inductive sensor or other solution. The combi-

nation of high stepper motor torque and Field Oriented

Controls (FOC) technology provides an innovative solution

and increased eciency. The automation uses a feedback

signal from the motor to make sure that it selects exactly

the required amount of current to achieve the required spe-

ed and torque.

The exchanger should be equipped with an anti-frost sys-

tem, which will protect the device against the eects of ex-

cessive cooling of the exhaust part of the exchanger.

The protection consists of (on delivery of the manufac-

turer’s automation):

• dierential pressure sensor (pressure switch) before and

behind the exchanger on the exhaust air side,

When the pre-set pressure drop on the pressure switch is

reached, as a result of the exchanger defrosting, the con-

troller sends a signal to the inverter to smoothly reduce the

rotor speed (system with inverter).

NOTE: The rotary exchanger is supplied without a frost

protection system as standard. The type of system is deter-

mined by the ventilation and automation system designer.

A pressure system is recommended. The pressure switch

setting should be 150% of the designed air pressure drop on

the exchanger on the outlet side.

The value of pressure drop is given in the technical data of

the air handling unit.

4.11.1 Technical parametres of rotary drivesr

Detailed data on the technical characteristics of rotor dri-

ves are available in a separate technical documentation:

KLIMOR_DTR_EVO_RR_CS_057.x.x_ issued with the AHU.

4.11.2 Operation of the rotary exchanger

The rotary exchanger should be inspected every 6/12

months. Aluminium lamellas can get dirty. Before clean-

ing rotary exchanger sections, the neighbouring sections

should be secured.

Clean with a vacuum cleaner with a soft suction nozzle on

the side of air inlets or blow through with air in the direction

opposite to the airow in the exchanger. The drive belt of

the rotary exchanger is an operating element and should

be shorten if an incorrect tension is noticed.

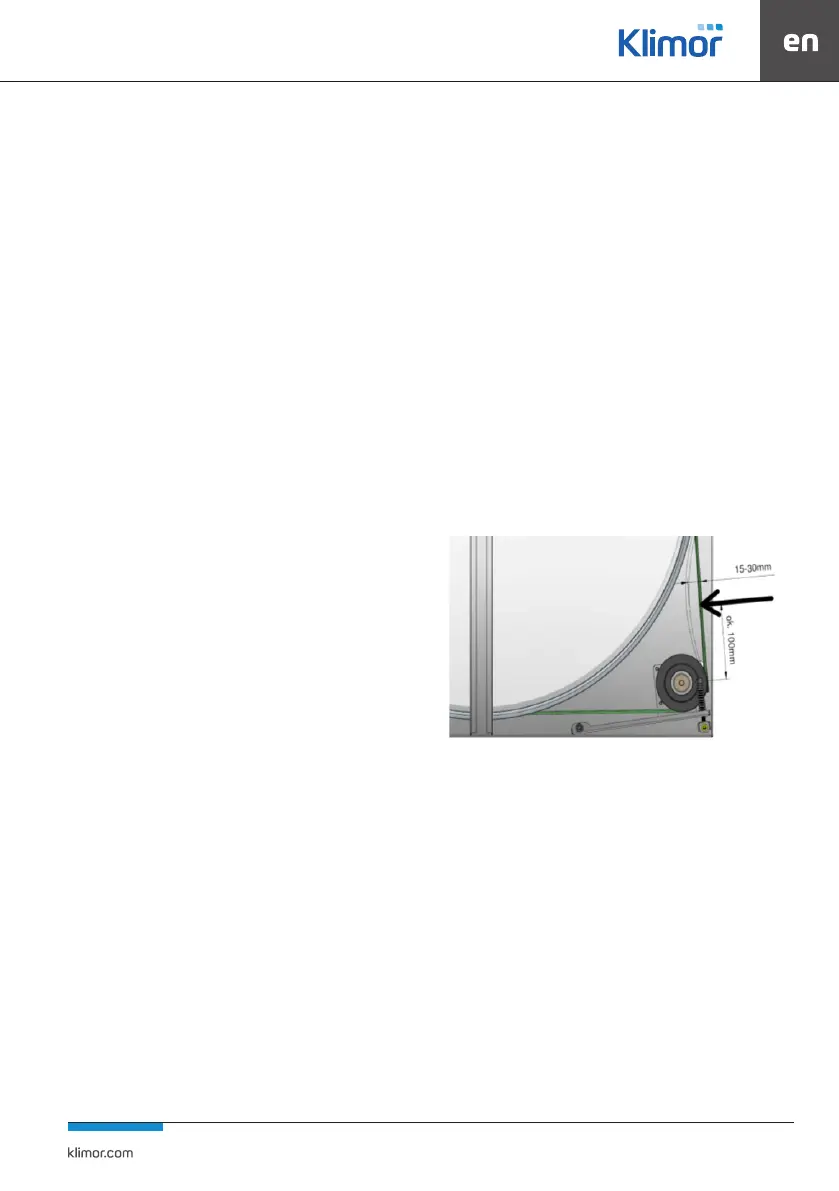

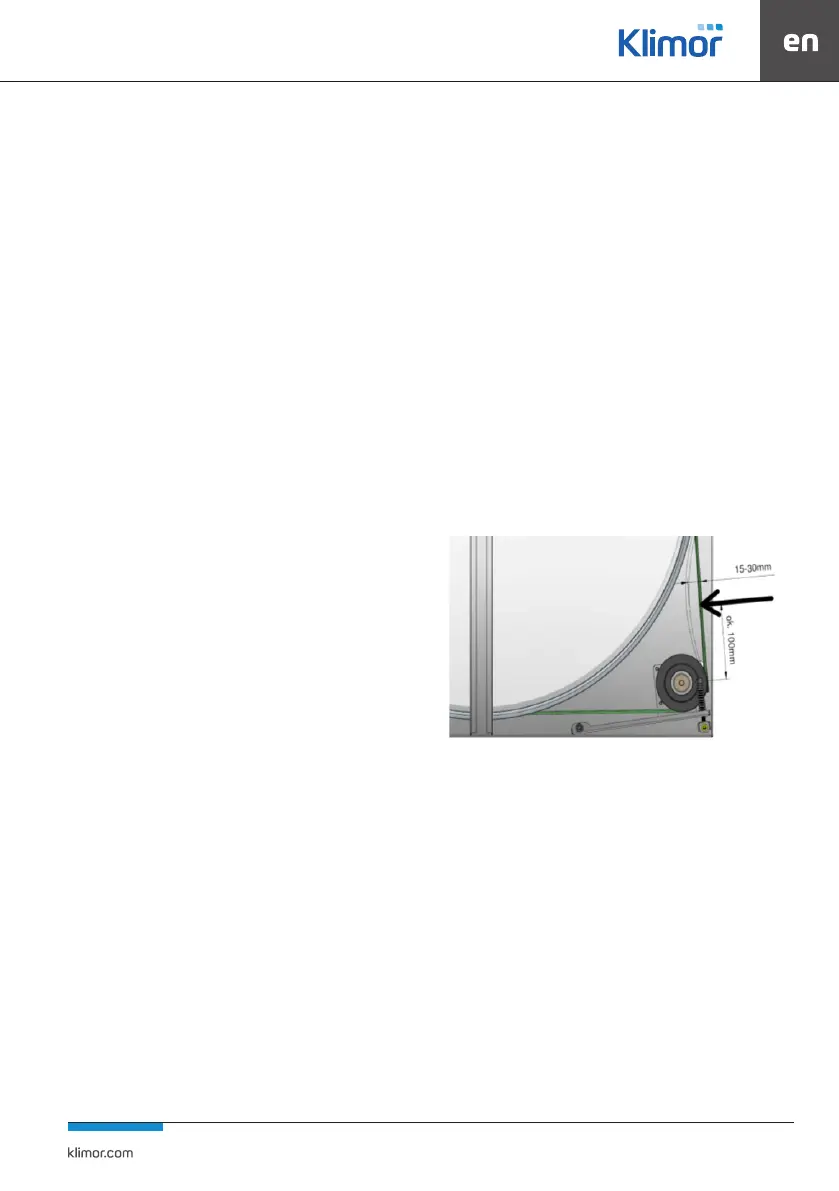

Fig. 75 Regulacja pasa napędowego

The tension of the drive belt must be controlled by pressing

the strap with moderate force with the nger at a distance

of about 100mm from the axis of the pulley. The deeeation

of the belt should be 15-30mm - as in the gure.

In case of greater deection, the belt should be shorte-

ned. For this operation, remove the belt from the pulley,

unscrew the connector (clasp), shorten the belt by the

required number of parcels of length (the graduation is

determined by holes in the belt), attach the clasp, turn

the clasp, put the belt on the pulley and make a deection

attempt.

Loading...

Loading...