74

EVO-S, EVO-H MODULAR AIR HANDLING UNITS

OPERATION AND MAINTENANCE MANUAL

Table 7 Dimensions of glands depending on the size of the unit

Motor power [kW] Size of the gland

< 3

3÷15

15÷30

30

P…11

P…16

P…21

P…29

Before connecting the motor to the installation, check the

resistance of the windings to ensure that they are not dam-

aged by humidity during storage.

Failure to do so may cause damage (combustion) to the

motor at start-up. When connecting motors and other elec-

trical equipment and components, it is essential to observe

the health and safety requirements contained in the rele-

vant standards and regulations for installing and operating

electrical equipment.

The electrical installation should meet the requirements

specied in the following standards and regulations (PN-HD

60364-1:2010; PN-HD 60364-5-54:2011 - Low voltage elec-

trical installations).

If the electrical switchboard is located in a dierent room

than the unit, it is absolutely necessary to install a START-

STOP switch (with interlock) in the room where the unit is

installed (as close to the unit as possible) for service switch-

o of the unit. The service switches, providing the ON/OFF

signal for the unit automatic system, are standard equip-

ment of the unit.

3.5.3 Draining out condensate

In the drip trays of the cooling block, humidier, cross-ow

exchanger and cooling set, there are drain stubs mounted

outside the unit. For AHU sizes 0230 and above, due to their

width, the connections are located on both sides of the unit.

Drain traps should be connected to the stubs to ensure

proper condensate drainage and prevent air suction. Traps

are included in delivery of the unit.

The trap used is an all-purpose device and may work on the

suction (underpressure) and pressing (overpressure) side

of the fan. The only requirement is a correct installation in

terms of the direction of ow on the condensate system -

the correct direction of installation is shown on the lid.

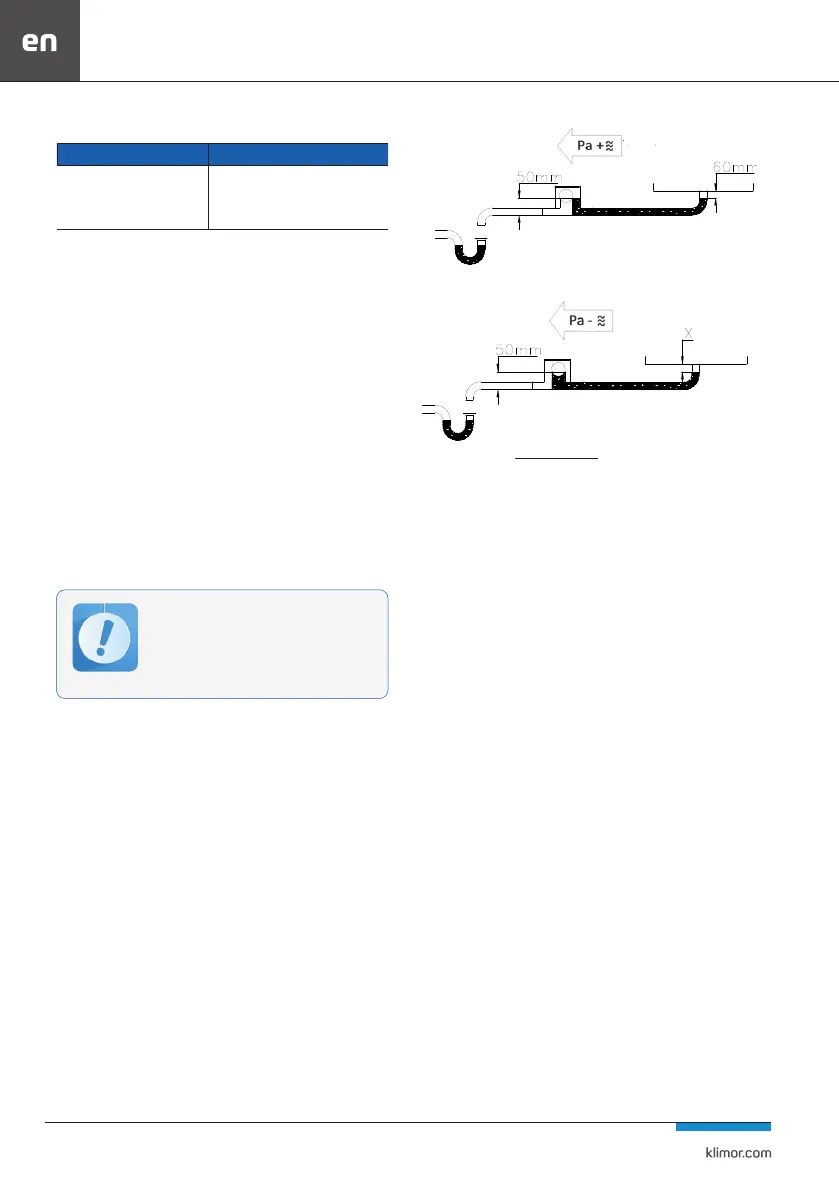

For a trap working on underpressure an appropriately

high terminal should also be made out of supplied PVC

pipes, working out value X where the trap is going to

operate.

For a trap working on overpressure, additionally the lid

should be opened, the black rubber plug removed, and

then the lid should be closed. The siphon trap set is also

equipped with additional installation instructions.

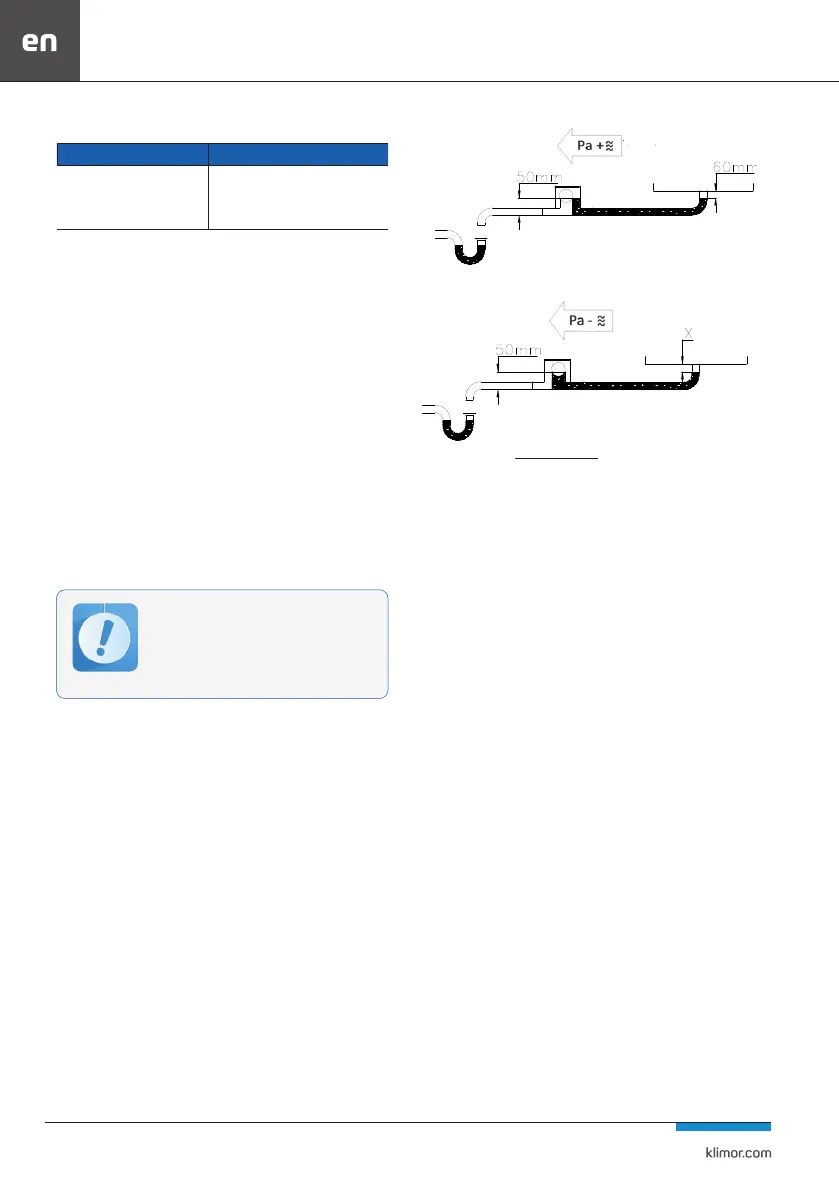

Fig. 37 A trap working on overpressure P+

(

Pa

pressure below atmospheric

)

10

+10mmX=

Fig. 38 A trap working on underpressure P-

3.6 Unit start-up

Start-up and operation of the air handling units may be per-

formed by authorized persons with theoretical and practical

knowledge of a given air conditioning or ventilation system

Before start-up:

1. Check the correctness of connection and tightness of in-

stallations connected to the unit.

2. In the ltering block, remove the foil from the lters (if

new), check cleanliness of the lters and their mounting in

the guides.

3. Check the xing of humidier (if any), heaters and coolers

along with their equipment.

4. In the fan block, check the state of fastening of the fan

unit.

5. Check the condition of electrical connections and the

wiring to avoid rubbing electric wires against moving parts.

6. Check that the fan rotor does not rub against the inlet

funnel mounted on the diaphragm during rotation.

7. Check the electrical connections of the fans depending

on the power supply (3×230V or 3×400V). The type of pow-

er supply for which the fan has been prepared should be

checked in the unit’s KDC. On the motor nameplate, check

the method of motor connection for a given power supply.

Then connect in the required way according to the scheme

in Fig. 39.

8. In case of fans with EC motors, use the scheme shown in

Fig. 40 for single-phase and Fig. 41 for three-phase EC fans

in order to connect them.

All works shown in point 3.5 should be car-

ried out according to individual schemes and

documentation and by employees authori-

zed to perform the above mentioned works.

Additionally, it is necessary to follow the

design and assembly recommendations inc-

luded in point 8.

Loading...

Loading...