85

4.3.5 Operation of passive-active lters

If the G4/ISO COARSE 80% pre-lter needs to be replaced,

check the state of the electrostatic lters. Clean them if you

notice any pollution, but not less frequently than once eve-

ry 6 months.

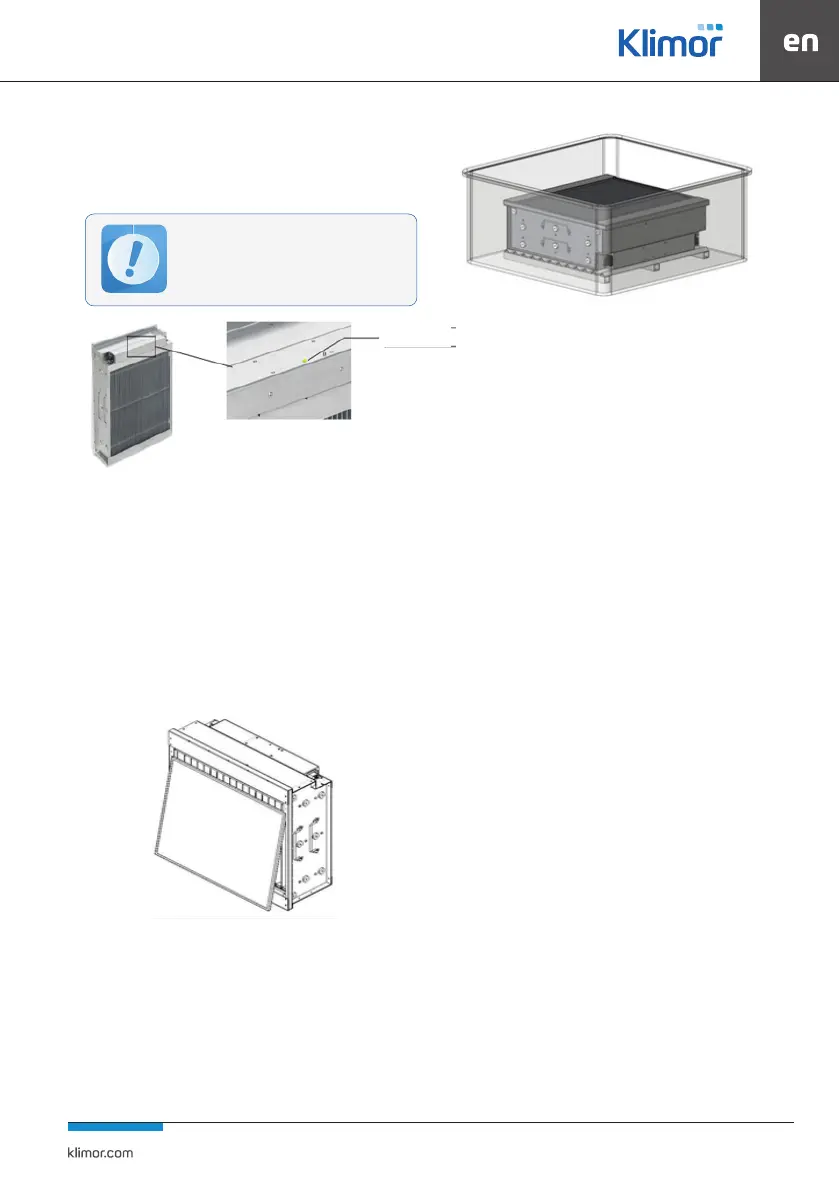

Fig. 57 Filter operation signalling

There is a green signal light in the electrostatic lter (Fig. 57),

which allows to visualize its correct operation.

A regular green signal means that the lter is working

properly, a ashing light means that the lter is faulty.

If the LED is not lit, check the electrical connections (no po-

wer supply).

To carry out correct maintenance, rst remove the pre-lter

from the cell (), lifting it by about one centimetre as shown

in the gure below

Fig. 58 Removing the pre-filter

Recommended materials for lter cleaning:

• Plastic or (INOX) container with bottom lifted to 2-3 cm

for dirt removal

• washing detergent

• gloves and goggles

• suitable clothing

• running water

Fig. 59 Filter cleaning

The cleaning process:

• dip the cell in the container as shown

• Leave it inside for the time suggested by the instructions for

use of the detergent or until the dirt is completely dissolved.

• remove the lter, rinse thoroughly under running water,

being careful not to damage the ionisation wires

• leave the lter to dry, to speed up the drying, you can place

the lter in a dry room with a maximum temperature of 60°C

• The pre-lter should be washed in the same way; during

washing, it should be handled with care to prevent defor-

mation or damage.

During each maintenance, it is recommended to check that

the lters are in good condition.

In the case of an electrostatic cell, the following items sho-

uld be checked:

• high voltage electrodes (anodes, wires)

• aluminium facings

• cathodes

• the high-voltage strip - whether it’s not burnt

• the cleanliness of the housing inside.

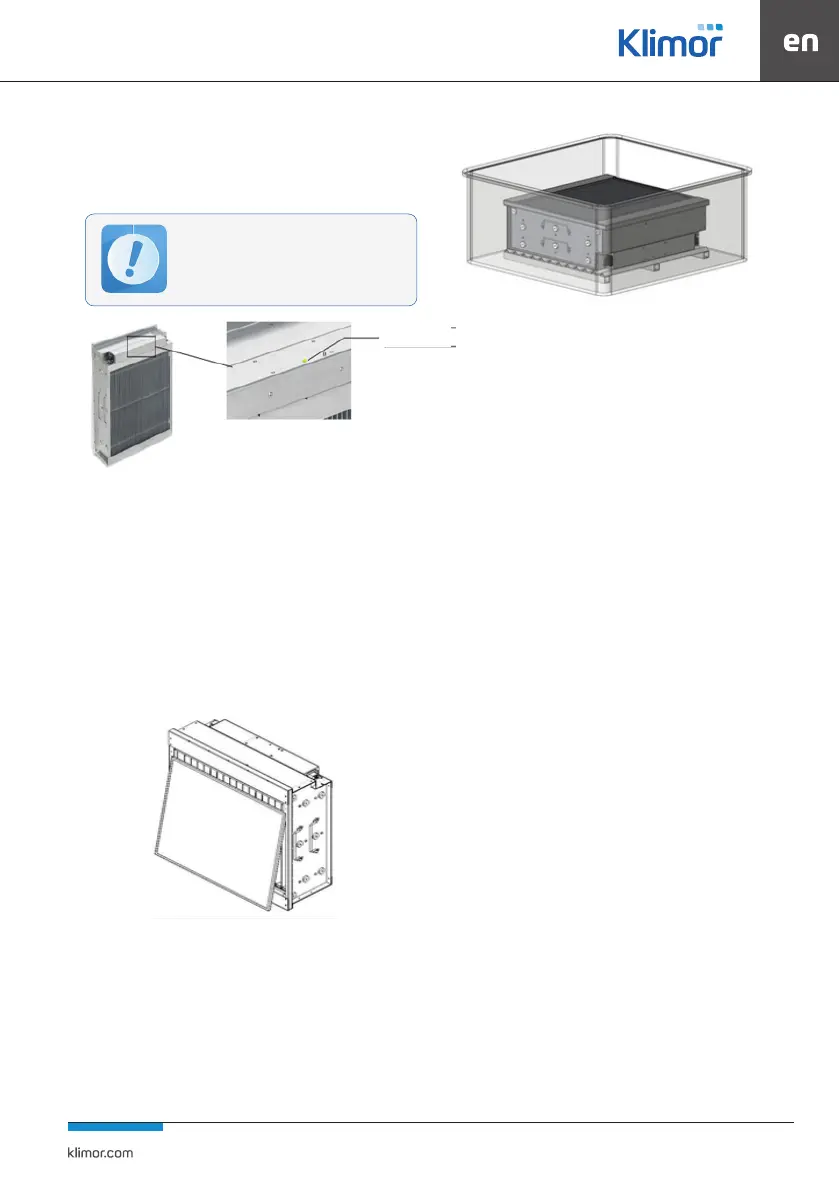

4.4 WH Water Heaters

A standard water heater consists of a galvanized sheet steel

housing and a CuAl package with copper tubes and alumi-

nium ns. The collectors and stubs are made of copper or steel.

The exchanger is equipped with drain and venting plugs.

During installation of the hydraulic system, it is recommen-

ded to supplement the pipes leading to the exchanger with

drain and vent valves.

When connecting the heaters to the supply system, it is ne-

cessary to follow the recommendations from chapter 4.8.1.

Dismantling the water exchanger involves unscrewing the

supply and return pipes, dismantling the casing panel from

the operating side and possibly removing the installation

from the section area. The exchanger can be removed.

In case of access to the exchanger section, also from the

opposite side of the automatic system’s operation, the pipes

are to be unscrewed

The rear cover has to be removed and the exchanger can

be pulled out.

Vertical elements of the exchanger casing that come into

contact with the unit casing are equipped with a self-adhe-

sive seal.

Before opening the inspection board, check

that the power supply of the electronic

motherboard and the electrostatic lter is

disconnected.

LED signal

Loading...

Loading...